Preparation method and application of camellia oil extract

A technology of extract and camellia oil, which is applied in the field of preparation of camellia oil extract, can solve problems such as poor hair absorption effect, underutilization of Camellia oleifera fruit nutrients, and poor hair damage effect, so as to improve the dissolution rate and improve biological Activity and stability, effect of promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

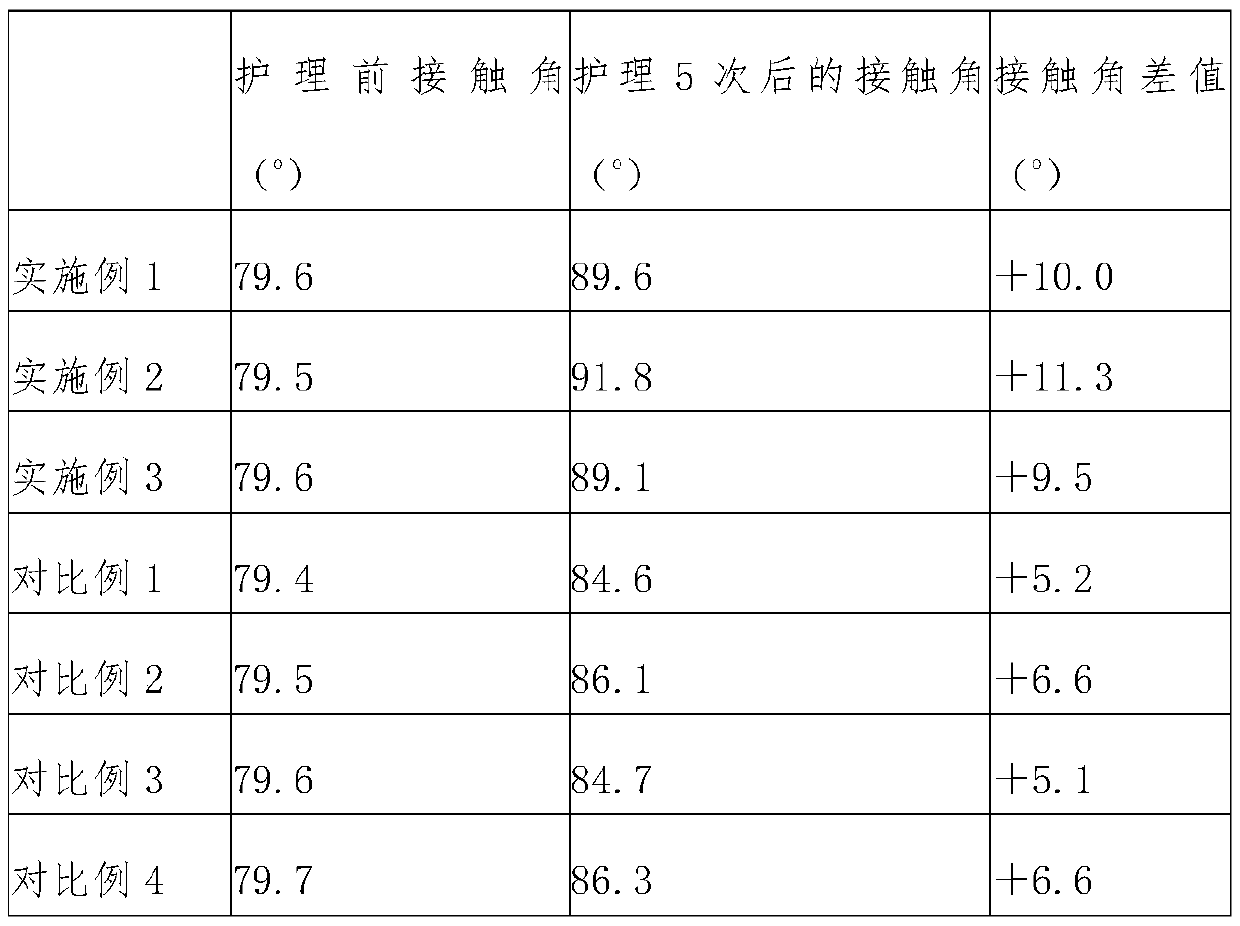

Examples

Embodiment 1

[0026] A preparation method of camellia oil extract, specifically comprising the following steps:

[0027] (1) Pulverization: take tea oil seeds and pulverize them into powder, add 30% of the treatment solution by mass and mix evenly, after compacting, first refrigerate at -4°C for 10h, then use 200°C steam for 30min, cool, and make get tea seed powder;

[0028] (2) Primary extraction: mix the tea seed powder and the organic acid extract in a mass ratio of 1:2, extract in a water bath at 40-45°C for 1 hour, and filter to obtain extract A and filter residue A;

[0029] (3) Secondary leaching: add alkaloid extract to the filter residue A and mix at a mass ratio of 1:5, extract in a water bath at 30-40°C for 2 hours, and filter with a filter press to obtain extract B and filter residue B;

[0030] (4) Composite fermentation treatment: take the filter residue B, add its mass 0.01w% bacterial solution 1 and mix, and ferment at 35-40°C for 12 hours to obtain the primary fermentati...

Embodiment 2

[0040] A preparation method of camellia oil extract, specifically comprising the following steps:

[0041] (1) Pulverization: Take camellia oil seeds and pulverize them into powder, add 32% of the treatment liquid by mass and mix evenly, after compacting, first refrigerate at -4°C for 11h, then use 200°C steam for 30min, cool, and make get tea seed powder;

[0042] (2) Primary extraction: mix the tea seed powder and the organic acid extract in a mass ratio of 1:3, extract 1.2 in a water bath at 40-45°C, and filter to obtain extract A and filter residue A;

[0043] (3) Secondary leaching: add alkaloid extract to filter residue A and mix at a mass ratio of 1:5, extract in a water bath at 30-40°C for 2.5 hours, and filter with a filter press to obtain extract B and filter residue B;

[0044] (4) Composite fermentation treatment: take the filter residue B, add its mass 0.012w% bacterial solution 1 and mix evenly, ferment at 35-40°C for 11 hours to obtain the primary fermentation...

Embodiment 3

[0054] A preparation method of camellia oil extract, specifically comprising the following steps:

[0055] (1) Pulverization: crush tea oil seeds into powder, add 40% of the mass of the treatment liquid and mix evenly, after compaction, first refrigerate at -2°C for 12h, then steam at 220°C for 20min, cool, and make get tea seed powder;

[0056] (2) Primary extraction: mix the tea seed powder and the organic acid extract in a mass ratio of 1:4, extract in a water bath at 40-45°C for 1.5 hours, and filter to obtain extract A and filter residue A;

[0057] (3) Secondary leaching: add alkaloid extract to the filter residue A and mix according to the mass ratio of 1:6, extract in a water bath at 30-40°C for 3 hours, and filter with a filter press to obtain the extract B and filter residue B;

[0058] (4) Composite fermentation treatment: take the filter residue B, add its quality 0.015w% bacterial liquid 1 and mix evenly, ferment at 35-40°C for 10 hours to obtain the primary fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com