Ultra-thin flat heat pipe liquid-absorbing core and manufacturing method thereof

A flat-plate heat pipe and liquid-absorbing core technology, applied in the field of heat transfer, can solve the problems of difficult production and utilization, increased gas and liquid flow resistance, high cost, etc. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

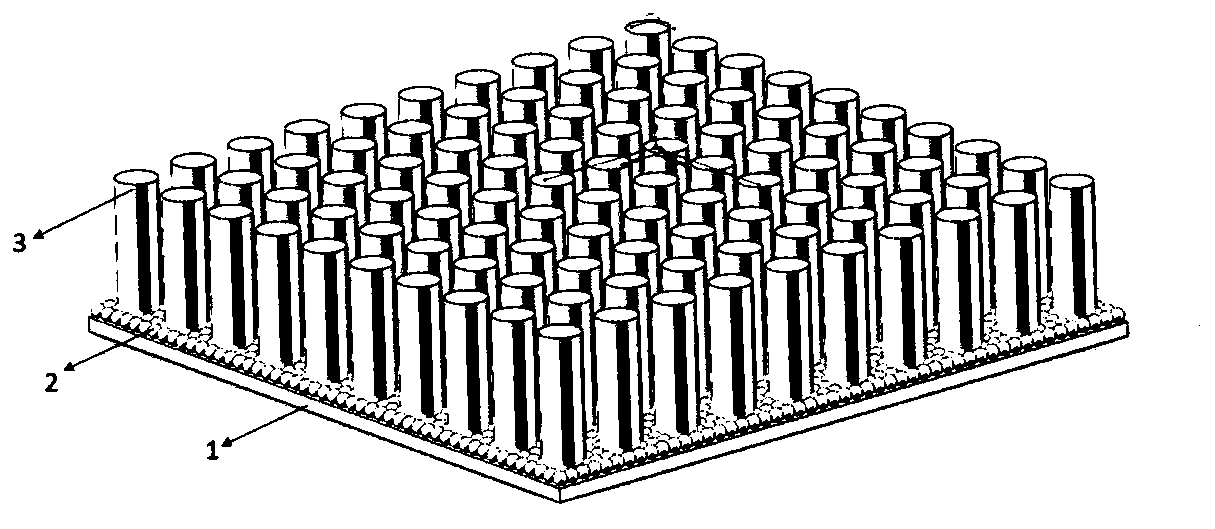

[0045] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0046] The substrate preparation process of the present invention is as follows:

[0047] (1) Selection of the substrate: select a copper foil with a thickness of 100 microns as the thermally conductive substrate;

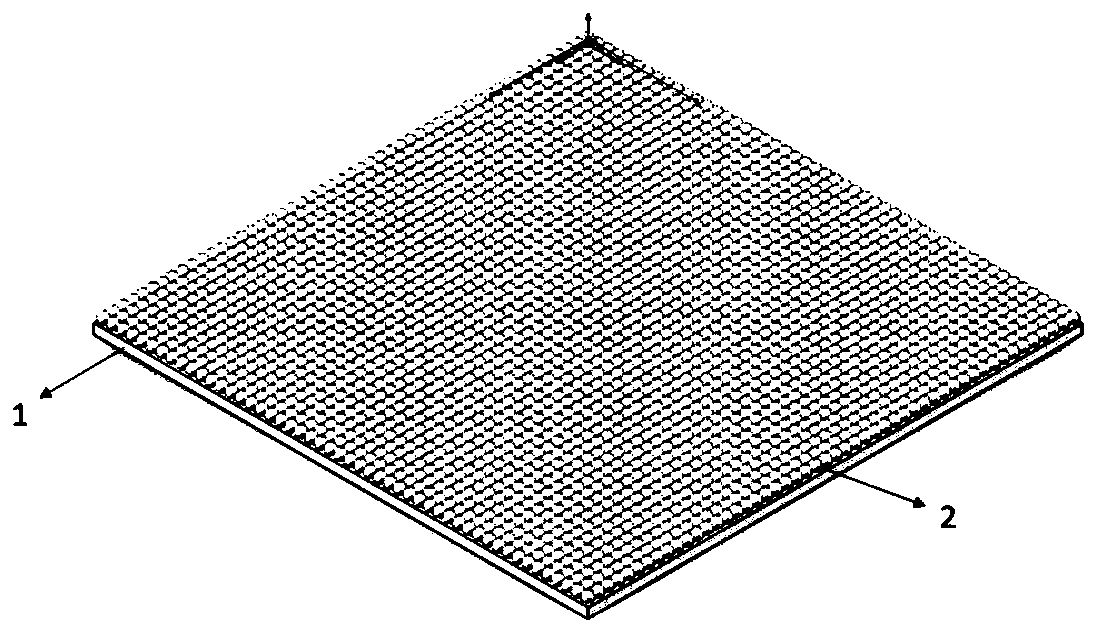

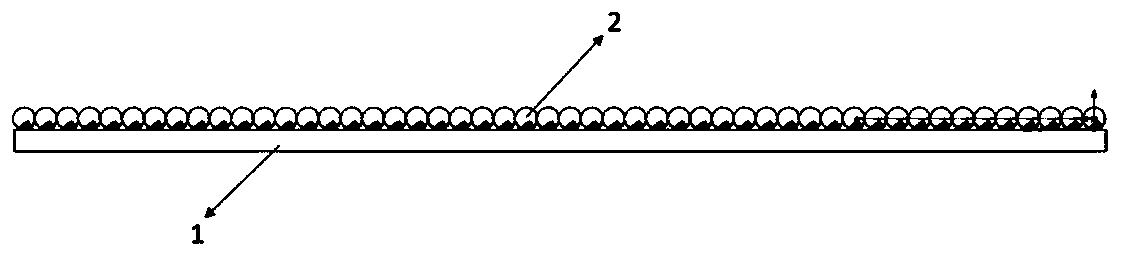

[0048] (2) The preparation process of the ordered structure: first put the copper substrate into the ultrasonic cleaning machine to clean it, and then vertically immerse the copper substrate into the monodisperse microsphere emulsion (nano-sized), and the copper substrate and the emulsion form a meniscus, such as Figure 9 shown. When the solvent is volatilized by heat, the liquid level drops slowly, and the microspheres at the meniscus self-assemble into a periodic structure from top to bottom on the copper substrate under capillary action, and finally obtain a well-ordered crystal colloid, su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com