Electric control impedance deploying chip based on radio frequency micro electro mechanical structure and microwave system

A micro-electromechanical structure, microwave system technology, applied in impedance networks, circuits, electrical components, etc., can solve problems such as requiring regular maintenance, restricting efficiency improvement, and difficult to achieve phase shift, achieving multi-channel work, improving adaptability, The effect of improving the working bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

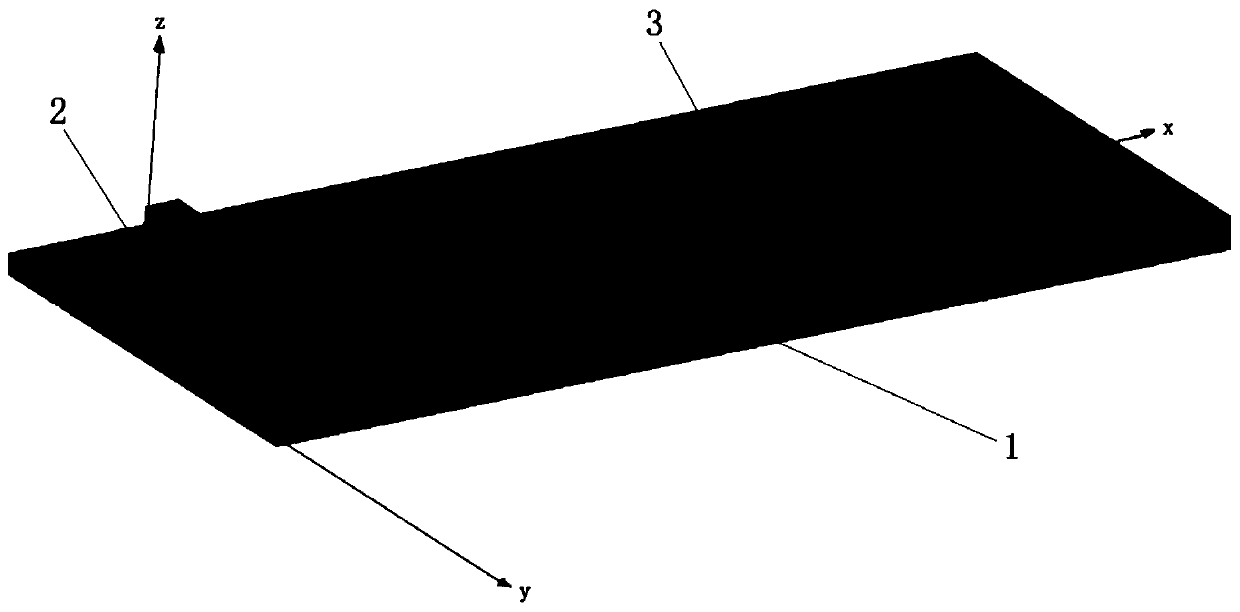

[0046] Such as figure 1 with 2 As shown, an electronically controlled impedance adjustment chip based on a radio frequency micro-electromechanical structure includes a chip substrate 1 and a MEMS impedance adjustment device, and the MEMS impedance adjustment device is designed and manufactured on the chip substrate 1; the MEMS impedance adjustment device includes A motor-type impedance adjuster or a switch-type impedance adjuster; the motor-type impedance adjuster includes a micro-electromechanical device 2 and a central conductor 3, and the micro-electromechanical device 2 includes a micro-motor with a radio-frequency micro-electromechanical structure and a microwave probe, so The micro motor drives the microwave probe to move along the axial direction of the central conductor 3 or along the vertical direction of the central conductor 3 .

[0047] The above-mentioned electronically controlled impedance adjustment chip is designed and processed on the substrate of the bare ch...

Embodiment 2

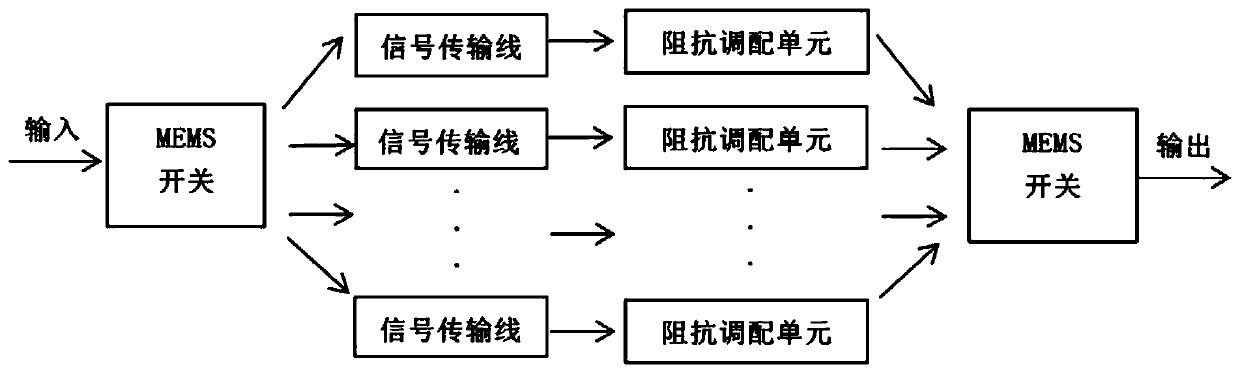

[0058] Such as figure 2 As shown, on the basis of Embodiment 1, another structural type for realizing the MEMS impedance adjuster——switch-type impedance adjuster is proposed. The switch-type impedance adjuster includes a MEMS switch, a signal transmission line, and an impedance adjustment unit. A MEMS switch is respectively arranged at the signal input and output ends, and several groups of signal transmission lines are connected in parallel between the two MEMS switches to form an impedance adjustment unit in series. components; the impedance adjusting unit is the motor-type impedance adjuster, or / and an adjustable resistor-inductance-capacitance array, or / and an adjustable active transistor array.

[0059]When the MEMS impedance adjuster adopts a switch-type impedance adjuster structure, several groups of signal transmission lines and impedance adjustment units can be connected in parallel between two MEMS switches, and each group of signal transmission lines and impedance ...

Embodiment 3

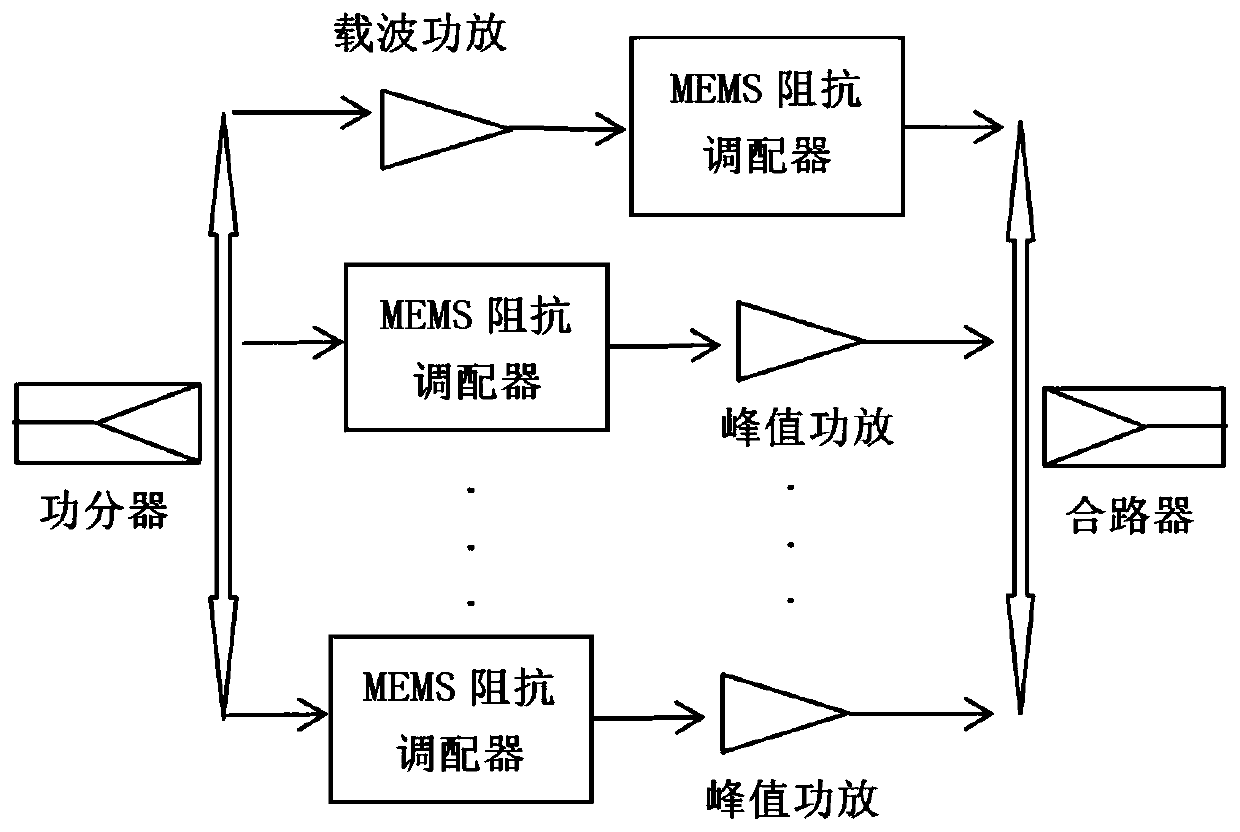

[0064] Such as image 3 As shown, on the basis of Embodiments 1 and 2, an electronically controlled impedance modulation microwave system based on radio frequency micro-electromechanical structure is realized, including a Doherty power amplifier microwave system or a TR transceiver module and a phased array microwave system; The Doherty power amplifier microwave system includes a power splitter, a combiner, a carrier power amplifier, a peak power amplifier, and a MEMS impedance adjuster; a carrier power amplifier and several peak power amplifiers are connected in parallel between the power splitter and the combiner. One MEMS impedance adjuster is connected in series between the carrier power amplifier and the combiner, and one MEMS impedance adjuster is connected in series between each peak power amplifier and power splitter.

[0065] The above-mentioned Doherty power amplifier microwave system replaces the 1 / 4 wavelength transmission line in the prior art with the MEMS impeda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com