Production method of gel polymer electrolyte porous membrane

A gel polymer and production method technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, electrochemical generator, etc., can solve the problems of incapable of industrialization and mass production, and achieve high production efficiency and high porosity , good structural consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

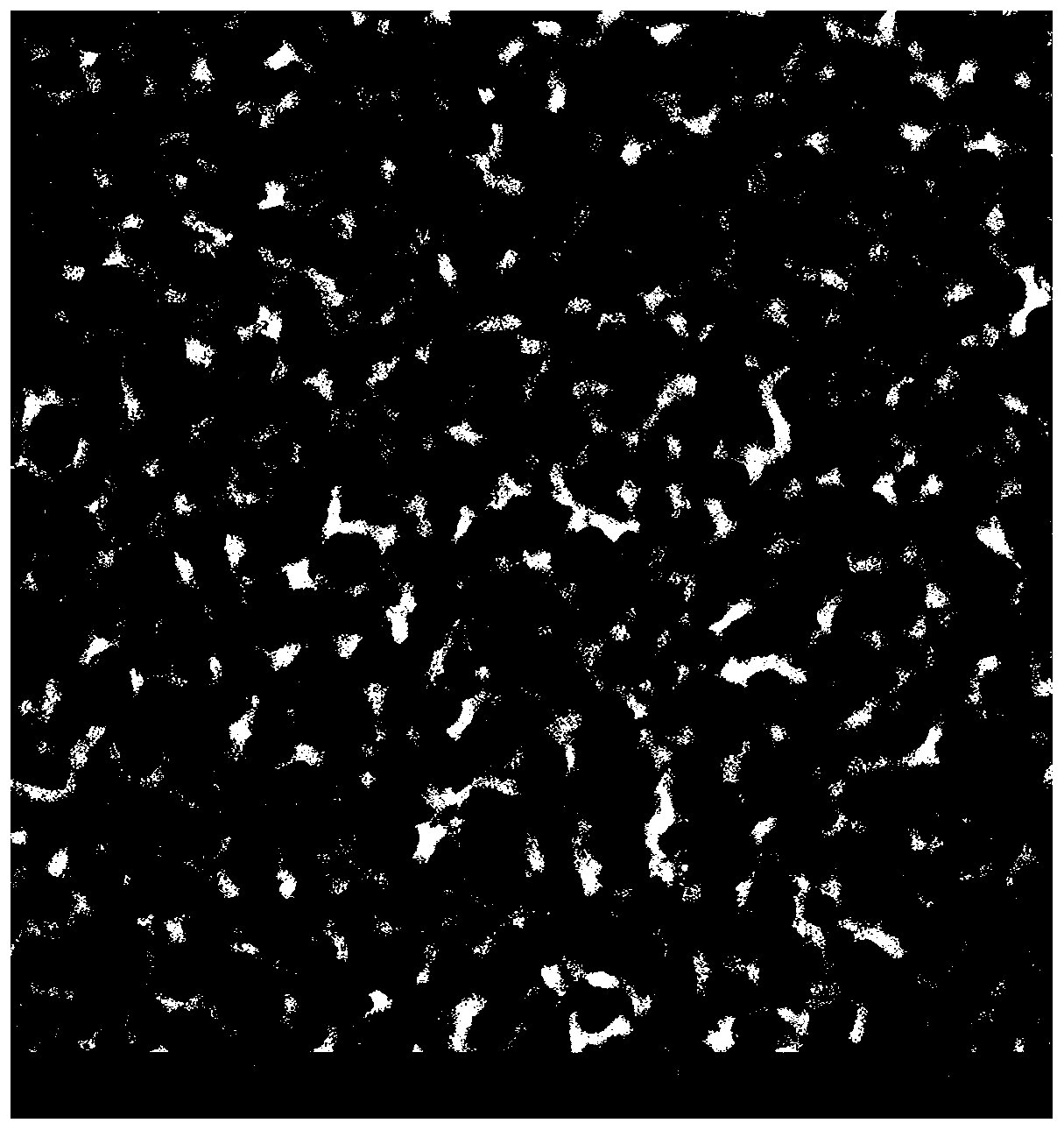

Image

Examples

Embodiment 2

[0058] Embodiment 2, embodiment 2 of the present invention provides a kind of production method of gel polymer electrolyte porous membrane, and its difference with embodiment 1 is, used solvent and non-solvent are DMF and glycerol, both mass ratio 85:15, wherein, the temperature of the first oven is 120°C, and the baking time is 7 minutes; the temperature of the second oven is 130°C, and the baking time is 4 minutes; the temperature of the third oven is 140°C, and the baking time is The time is 7 minutes.

Embodiment 3

[0059] Embodiment 3, embodiment 3 of the present invention provides a kind of production method of gel polymer electrolyte porous membrane, and its difference with embodiment 1 is that used solvent and non-solvent are DMF and n-butanol, and the mass ratio of both is 90:10, wherein the temperature of the first oven is 110°C, and the baking time is 5 minutes; the temperature of the second oven is 120°C, and the baking time is 7 minutes; the temperature of the third oven is 130°C, and the baking time is 5 minutes. It is 7min.

Embodiment 4

[0060] Embodiment 4, embodiment 4 of the present invention provides a kind of production method of gel polymer electrolyte porous membrane, and its difference with embodiment 1 is, used solvent and non-solvent are DMAc and ethylene glycol, both mass ratio It is 90:10, wherein, the temperature of the first oven is 110°C, and the baking time is 2 minutes; the temperature of the second oven is 120°C, and the baking time is 5 minutes; the temperature of the third oven is 130°C, and the baking time is 2 minutes. The time is 7 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com