A kind of composite metal oxide solid base catalyst, preparation method and application

A solid base catalyst and composite metal technology, applied in the field of composite metal oxide solid base catalyst and preparation, can solve the problems of difficult separation of catalyst and product, environmental pollution, etc., achieve excellent oxygen storage/release capacity, reduce pollution degree, The effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Solid base catalyst K 2 O / CeO 2 @ZrO 2 Preparation of (KCZ)

[0043] (1) The composite metal oxide solid base catalyst K 2 O / CeO 2 @ZrO 2 The preparation steps of (KCZ) are as follows:

[0044] a, molar ratio n(Ce):n(Zr)=0.05:1, weigh 12g ZrOCl 2 ·8H 2 O and 0.8gCe (NO 3 ) 3 ·6H 2 The mixed solution was prepared in 100ml of water and transferred to a three-necked flask. Under the condition of a water bath at 30°C, the mixture was continuously stirred and slowly dripped with ammonia water, adjusted to pH 11, and continued to be stirred for 8h to fully react. After ultrasonication, aging, suction filtration and drying, rinse Cl with distilled water - , to obtain the precursor;

[0045] b. Put the prepared carrier precursor in 0.5mol / L KNO under the condition of water bath at 75℃ 3 Immerse in the solution for 12h, filter, dry, and calcinate at 700°C for 6h to obtain a solid base catalyst KCZ. KCZ is measured by ICP-AES. 2 The O loading was 5% (wt.%...

Embodiment 2

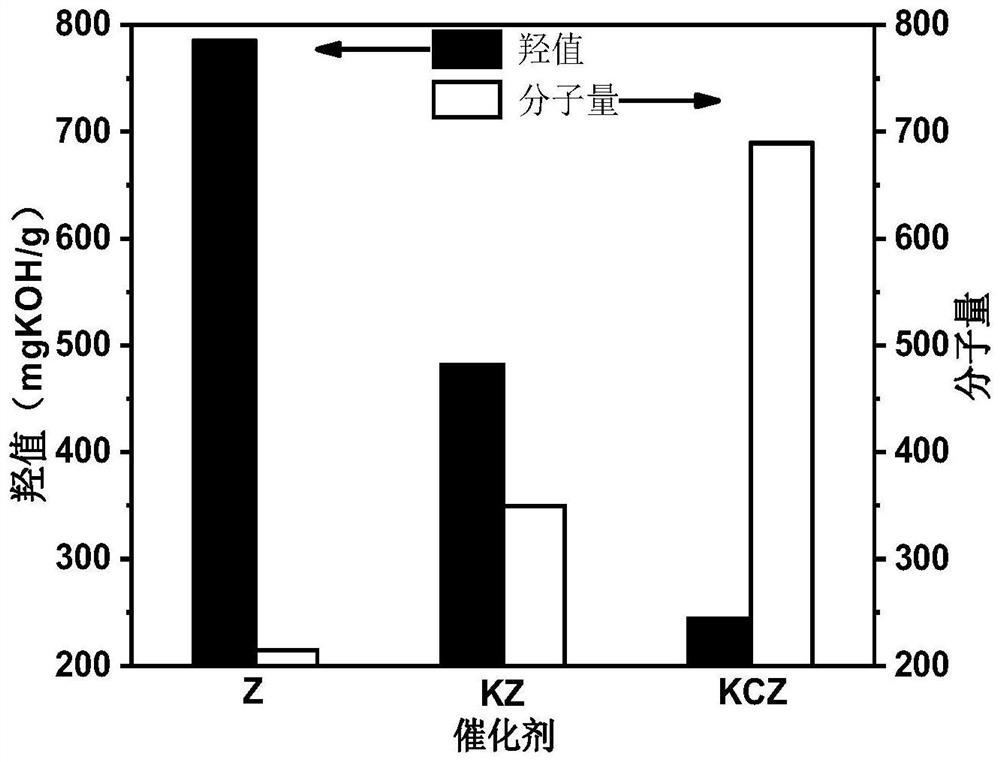

[0052] Example 2: Polypropylene glycol synthesis

[0053] The reactants glycerol, propylene oxide and catalyst were placed in a high-pressure reaction kettle. Before the reaction, a sufficient amount of nitrogen was introduced to replace the air in the kettle, and the reaction was polymerized for 6h under the conditions of an initial pressure of 2MPa, a temperature of 180°C, and a rotation speed of 350r / min. Wherein the raw material mass ratio m (glycerol): m (propylene oxide)=0.1:1, respectively use the catalyst prepared by embodiment 1, comparative example 1-2, catalyze the synthesis of polypropylene glycol, the usage amount of the catalyst is m ( catalyst): m (propylene oxide) = 0.06:1.

[0054] Filtration: The reacted product is taken out from the kettle and separated by suction filtration. In the first step, a double-layer medium-speed qualitative filter paper is used for filtration, and the pore size of the filter paper is 30-50 μm; in the second step, a double-layer sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com