Resistance heating forming method of carbon fiber reinforced high-performance thermoplastic composite material

A technology that enhances thermoplasticity and composite materials. It is applied in the field of composite material molding. It can solve the problems of low energy utilization, low efficiency, and long heating time, and achieve the effects of short molding cycle, simple process, and high energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

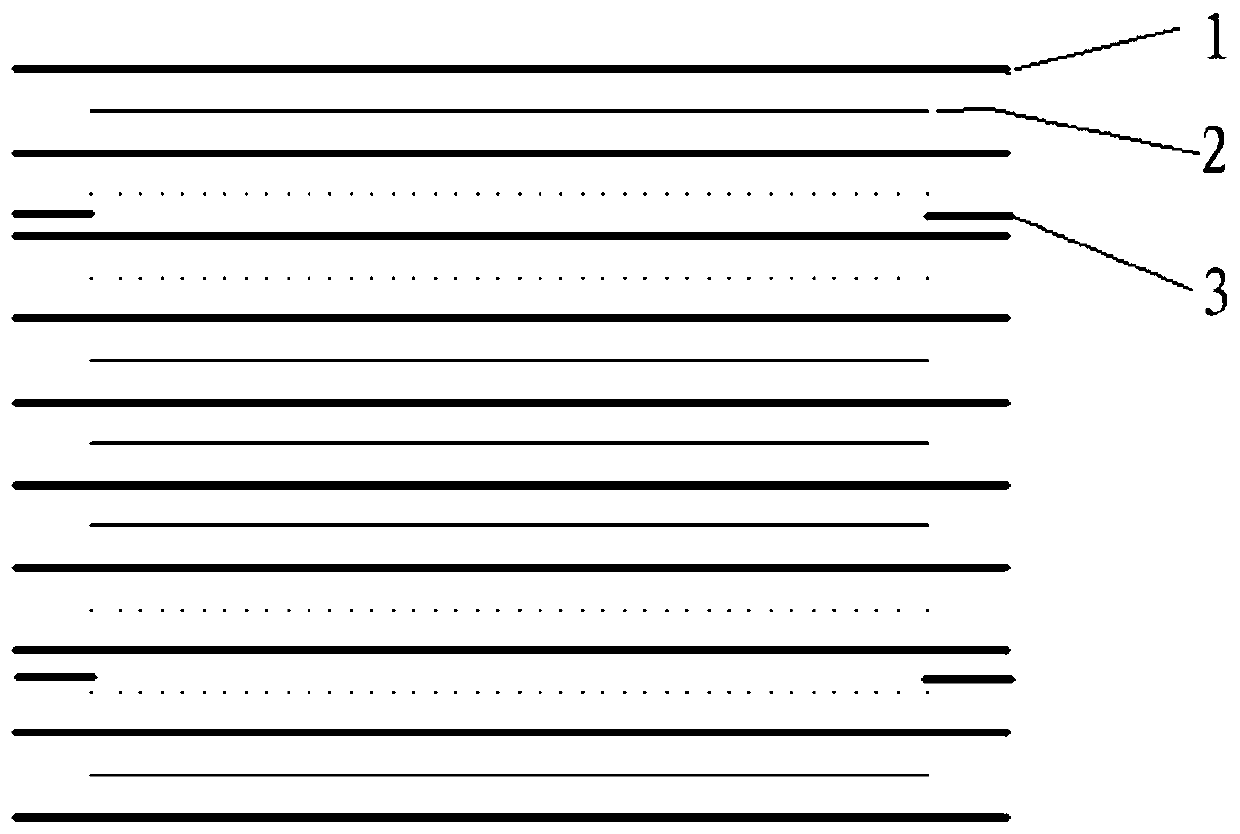

Image

Examples

Embodiment 1

[0040] The resistance heating forming method of CCF3011 carbon fiber plain weave fabric / polyamide film composite material comprises the following steps:

[0041] Blank: prepare 220mm×200mm, area density 200g / m 2 12 sheets of CCF3011 carbon fiber plain weave fabric, the size is 200mm×200mm, the surface density is 92g / m 2 , 26 pieces of polyamide film with a thickness of 0.05mm, leaving a 200mm×10mm area at each end of the carbon fiber fabric length direction as the electrode area, and aligning them in the center according to the order of two layers of resin film and one layer of carbon fiber fabric. Get the green body. A layer of polytetrafluoroethylene release cloth is placed on the upper surface and the lower surface of the green body, and then fixed with clips to facilitate electrode installation.

[0042] Install electrodes: Cut 2 pieces of copper foil of 230mm×10mm×0.065mm as the positive and negative electrodes, and place them in the electrode area at both ends of the c...

Embodiment 2

[0049] The resistance heating forming method of T300 carbon fiber fabric / polyphenylene sulfide powder composite material comprises the following steps:

[0050] Billet: cutting size is 330mm×260mm, area density is 200g / m 2 27 layers of T300 carbon fiber fabric, weigh 164g of polyphenylene sulfide powder according to the weight ratio of carbon fiber fabric and polyphenylene sulfide powder of 64:36, and divide it into 26 parts with a particle size of 0.070mm. A 260mm×20mm area is left at both ends of the carbon fiber fabric in the length direction as an electrode area for laying electrodes, and is protected with cardboard to avoid contamination with powder. First lay a layer of polytetrafluoroethylene release cloth on the rigid formwork, and then evenly disperse 1 part of polyphenylene sulfide powder on the carbon fiber fabric. The area of the resin powder is 290mm×260mm, and then lay the second layer of carbon fiber The fabric and resin powder are placed in this order to obt...

Embodiment 3

[0058] The resistance heating forming method of T700 multiaxial carbon fiber fabric / polyimide powder composite material comprises the following steps:

[0059] Billet: cutting size is 300mm×270mm, surface density is 300g / m 2 30 layers of T700 multi-axial carbon fiber fabric, weigh 486g of polyimide powder according to the weight ratio of carbon fiber fabric and polyimide powder of 60:40, and divide it into 29 parts with a particle size of 0.180mm. An area of 270mm×25mm is left at both ends of the carbon fiber fabric in the length direction as an electrode area for laying electrodes, and is protected by cardboard to avoid contamination with powder. First lay a layer of polytetrafluoroethylene release cloth on the rigid formwork, then evenly disperse 1 part of polyimide powder on the carbon fiber fabric, the area of the resin powder is 250mm×270mm, and then lay the second layer of carbon fiber The fabric and resin powder are placed in this order to obtain the green body, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com