Graphite-phase carbon nitride material for catalytic reduction of p-nitrophenol as well as preparation method and application of graphite-phase carbon nitride material

A technology of graphite phase carbon nitride and p-nitrophenol, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high catalyst cost and unsuitability for large-scale production, and achieve Conducive to adsorption, multiple active sites, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

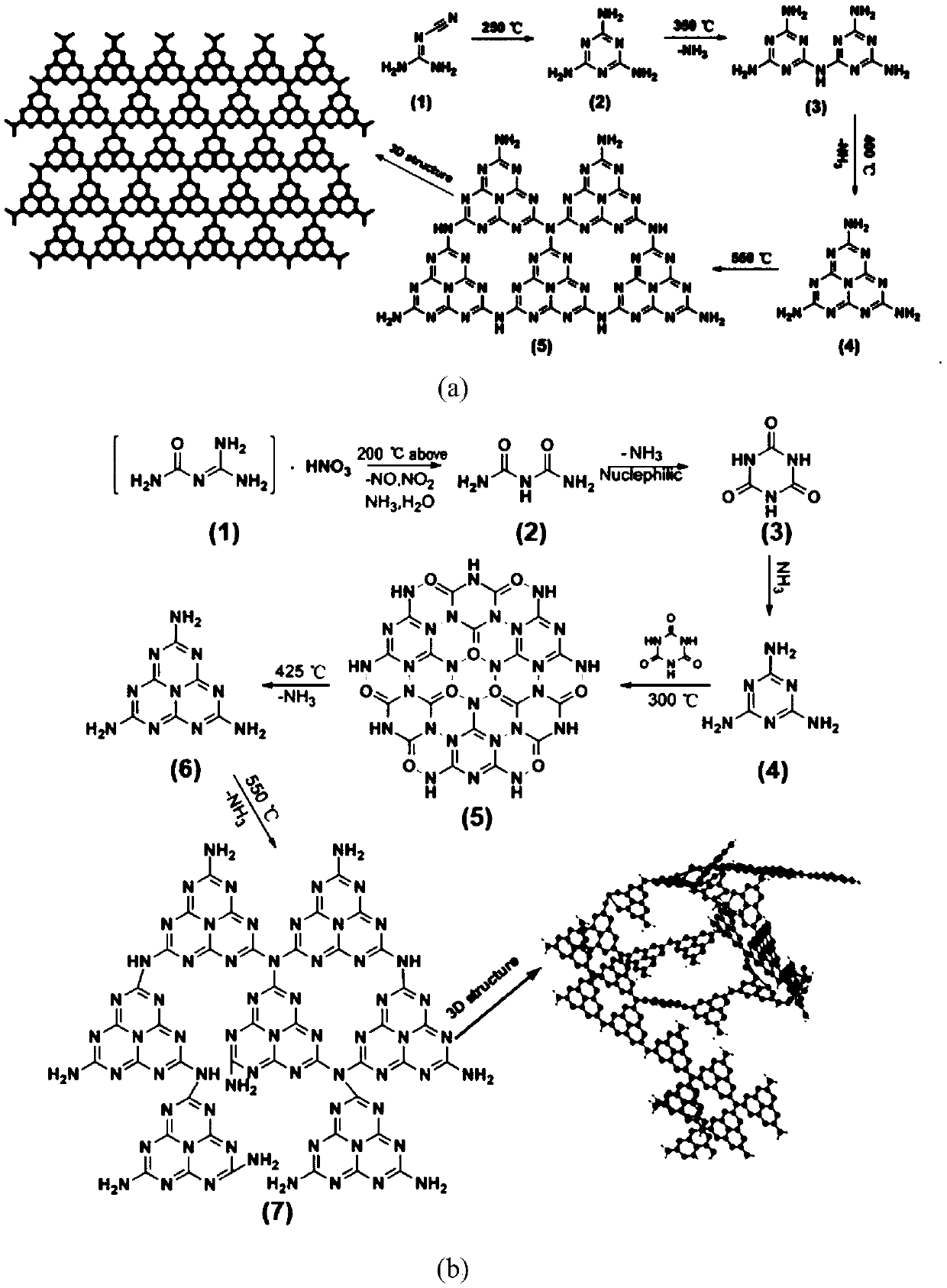

[0021] The preparation steps of graphite phase carbon nitride of the present invention and catalytic reduction process are as follows:

[0022] In the first step, dicyandiamide is dissolved in deionized water, heated and stirred at 40-45 °C for 30-60 min;

[0023] In the second step, slowly drop concentrated nitric acid with a volume ratio of 1:5 to 8 into the solution of the first step, and stir for 120-180 min;

[0024] In the third step, the reaction solution in the second step is cooled and crystallized in a mixed solution of ice and water, dried at 50-60° C., and dried to obtain amidinourea nitrate;

[0025] The fourth step is to roast the amidinourea nitrate obtained in the third step at 550±10° C. for 2-4 h to prepare graphite phase carbon nitride;

[0026] The fifth step, weigh an appropriate amount of graphite phase carbon nitride in the catalytic tube, add p-nitrophenol ( p- NP) and reducing agent sodium borohydride (NaBH 4 ), the reaction was carried out at room ...

Embodiment 1

[0029] In the first step, 2 g of dicyandiamide was dissolved in 40 mL of deionized water, heated and stirred at 40°C for 60 min;

[0030] In the second step, slowly drop concentrated nitric acid (5mL) with a volume ratio of 1:8 into the solution of the first step, and stir for 120 min;

[0031] In the third step, the reaction solution in the second step is cooled and crystallized in a mixed solution of ice and water, dried at 60° C., and dried to obtain amidinourea nitrate;

[0032] In the fourth step, calcining the amidinourea nitrate obtained in the third step at 550±10°C for 4 h to obtain graphitic carbon nitride 5H-CN;

[0033] The fifth step, weigh 1 mg 5H-CN in the catalytic tube, add 25mLH 2 O. 25mL p- NP (20mg / L)

[0034] and 25 mg NaBH 4 , react at room temperature.

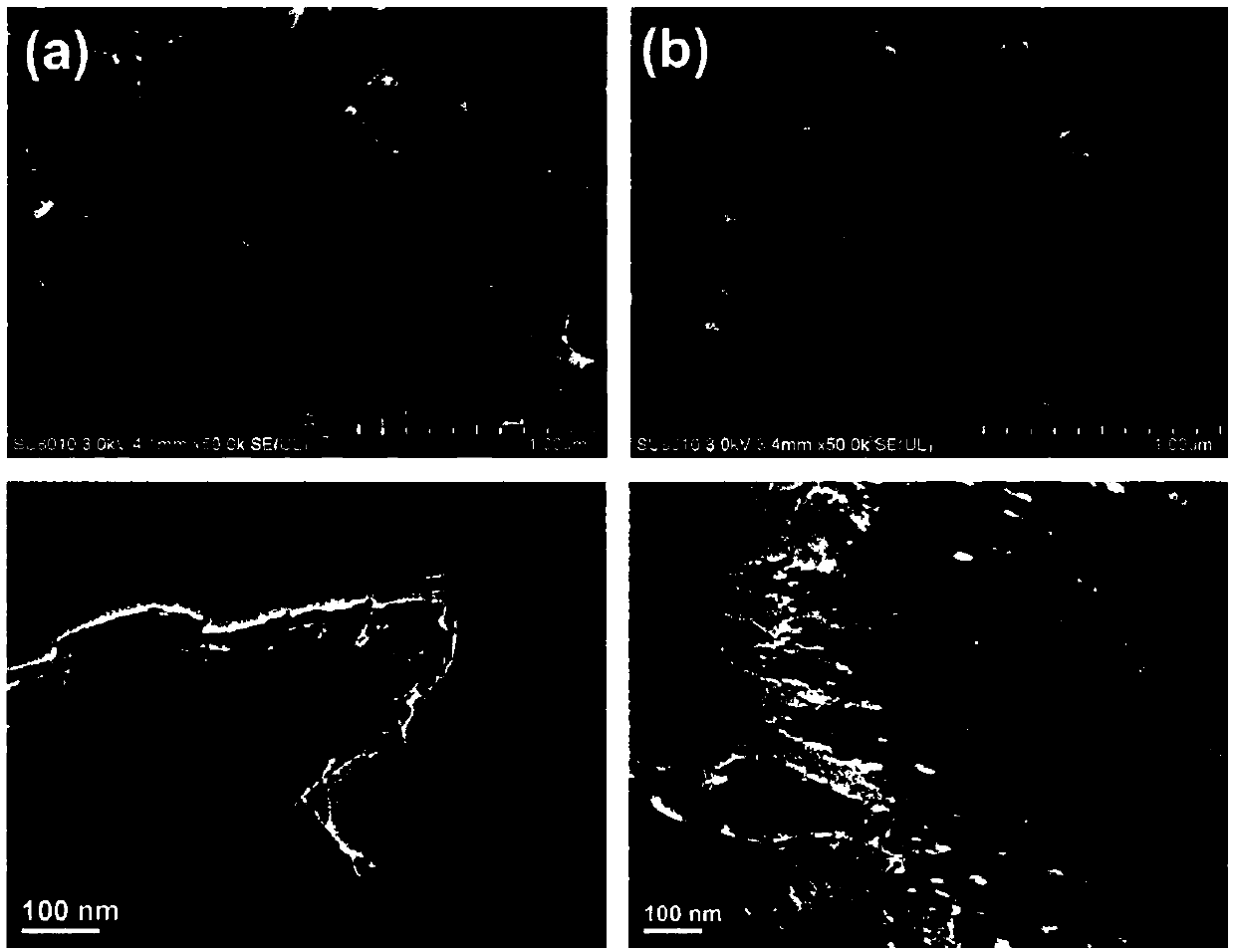

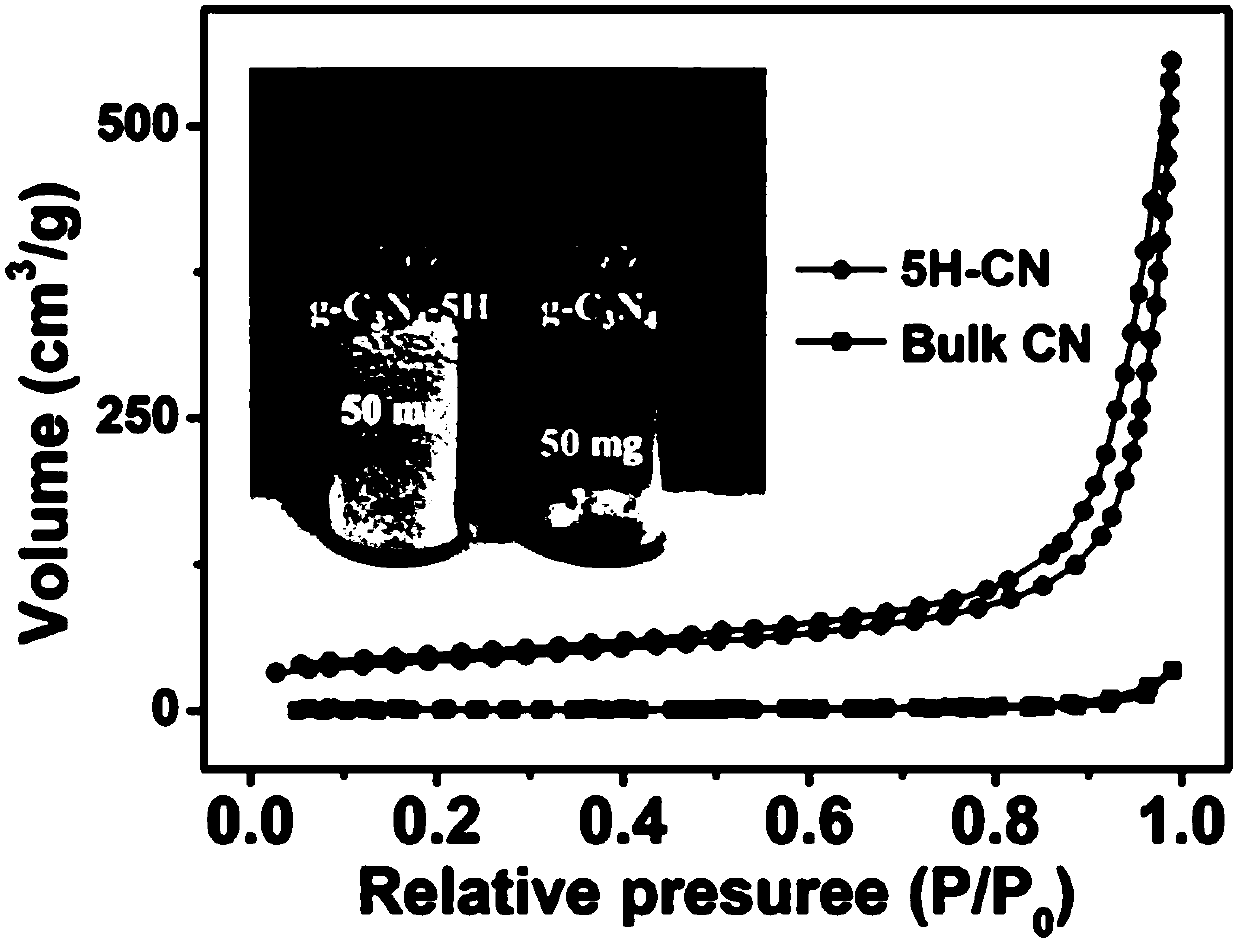

[0035] The prepared 5H-CN, its field emission scanning electron microscope and transmission electron microscope such as figure 2 As shown, BET as image 3 shown.

[0036] Catalytic reduction of ...

Embodiment example 2

[0038] In the first step, 2 g of dicyandiamide was dissolved in 40 mL of deionized water, heated and stirred at 45 °C for 30 min;

[0039] In the second step, slowly drop concentrated nitric acid (8 mL) with a volume ratio of 1:5 into the solution of the first step, and stir for 180 min;

[0040] In the third step, the reaction solution in the second step is cooled and crystallized in the ice-water mixture, and dried at 50°C;

[0041] In the fourth step, the amidinourea nitrate obtained in the third step was calcined at 550 °C for 2 h to prepare graphitic carbon nitride 8H-CN.

[0042] The fifth step, weigh 1 mg8H-CN in the catalytic tube, add 25mLH 2 O. 25mL p- NP (20mg / L)

[0043] and 25 mg NaBH 4 , react at room temperature.

[0044] The result is as Figure 4 Shown, room temperature catalytic reduction p- After 14 min of reaction, the reduction rate of NP reached 90.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com