Ultralight armored product and preparation method thereof

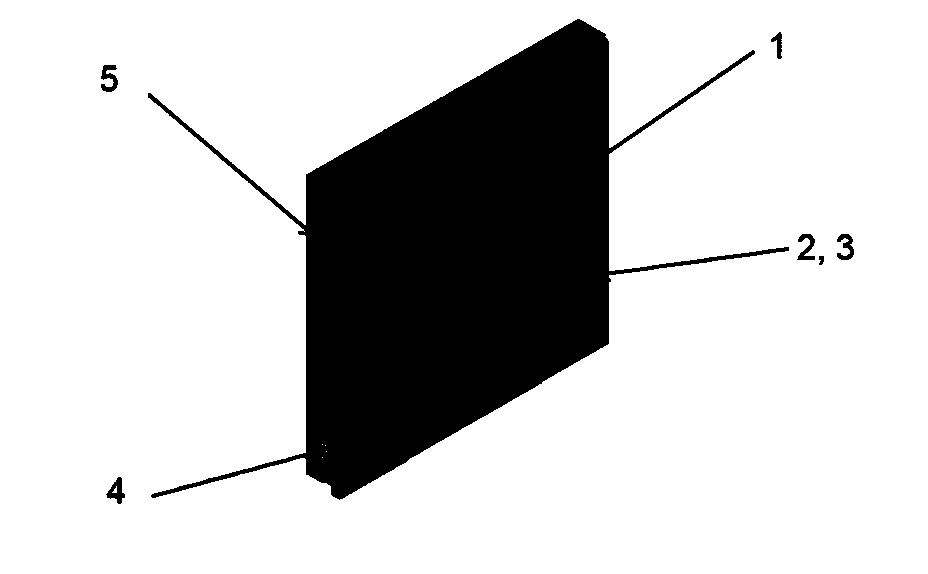

A light armor and product technology, applied in armor, protective equipment, layered products, etc., can solve the problems of large impact deformation, inability to provide structural support, insufficient rigidity, etc., and achieve the effect of improving ballistic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

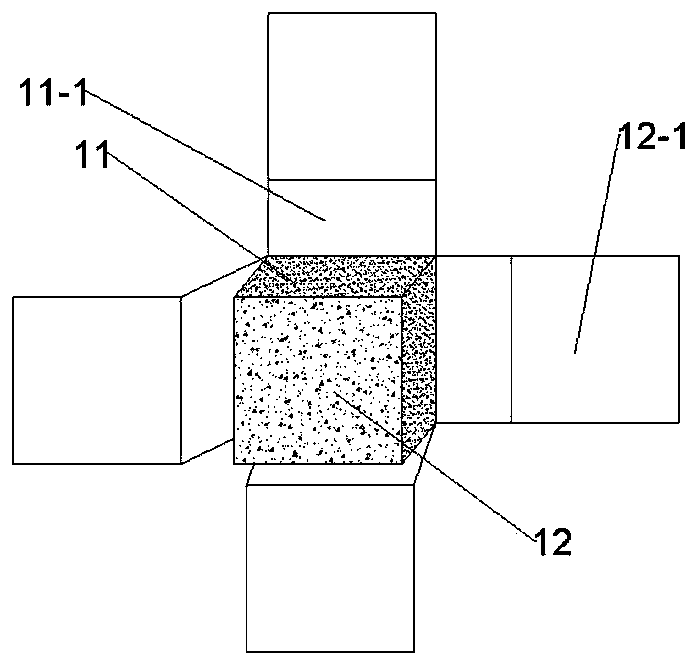

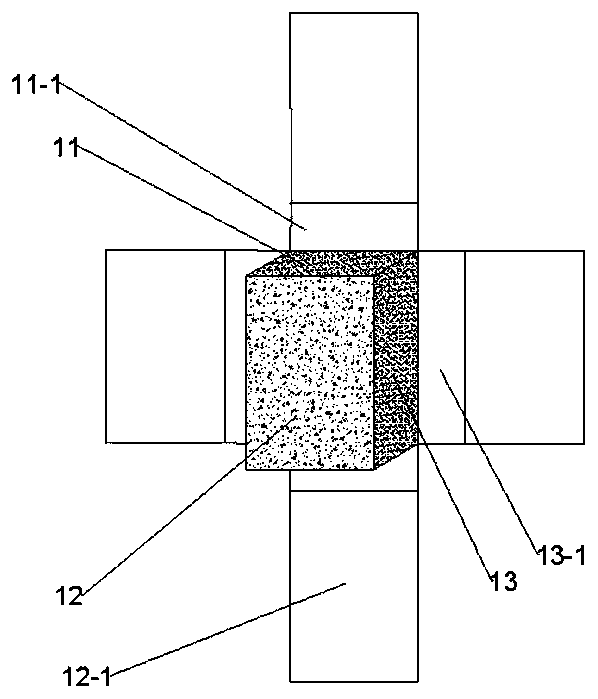

[0073] Select a square AD99 alumina ceramic block with a side length of 50mm, 4.5mm thick, and use a plain aramid fiber cloth with a thickness of 0.2mm to package the ceramic block: first design the fiber cloth cutting drawing, according to figure 2 As shown, the center of the cross-shaped fiber cloth is a 50mm square, and the four branches are a rectangle of 50mm×54.5mm. The aramid fiber cloth is cut on a computer-aided laser cutting machine; the cut fiber cloth is according to figure 2 The shown ceramic block is wrapped on the surface of the small ceramic block to form a package.

[0074] In addition, cut three pieces of 0.2mm thick aramid fiber cloth that meet the appearance size of the armor, and one of the fiber cloths is bonded to a 5mm thick 6061-T6 aluminum alloy plate with epoxy resin (provided by Beijing Iridium Platinum Industry and Trade Co., Ltd.) surface, and then the above-mentioned multiple packaged ceramic small pieces are coated with epoxy resin and bonded to...

Embodiment 2

[0081] Select a square AD99 alumina ceramic block with a side length of 50mm, 5.72mm thick, and use a 0.2mm thick plain weave glass fiber cloth to package the ceramic block: first design the fiber cloth cutting drawing, according to figure 2 As shown, the center of the cross-shaped fiber cloth is a 50mm square, and the four branches are a rectangle of 50mm×55.8mm. Cut the glass fiber cloth on a computer-aided laser cutting machine; cut the fiber cloth according to figure 2 The ceramic nubs are wrapped to form encapsulated ceramic nubs.

[0082] In addition, cut out three pieces of 0.2mm thick glass fiber cloth with the appearance size of the armor, one of which is bonded to the surface of the 6mm thick 6061-T6 aluminum alloy plate with epoxy resin, and then the above-mentioned multiple packaged ceramic small Block coated epoxy bonded to the surface of the fiber cloth.

[0083] The remaining two sheets of glass fiber cloth are covered and bonded (by epoxy resin) to the upper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com