Biodegradable polymer composite with high thermal conductivity and preparation method thereof

A technology of biodegradation and composite materials, which is applied in the field of high thermal conductivity biodegradable polymer composite materials and its preparation, can solve the problems such as the decline of mechanical properties of materials, achieve the improvement of mechanical properties, the preparation method is simple and easy, and the glass transition can be improved The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] S1: 1g of polypropylene carbonate and 25ml of N-N dimethylformamide are ultrasonically stirred for 2 hours to completely dissolve to obtain dispersion A;

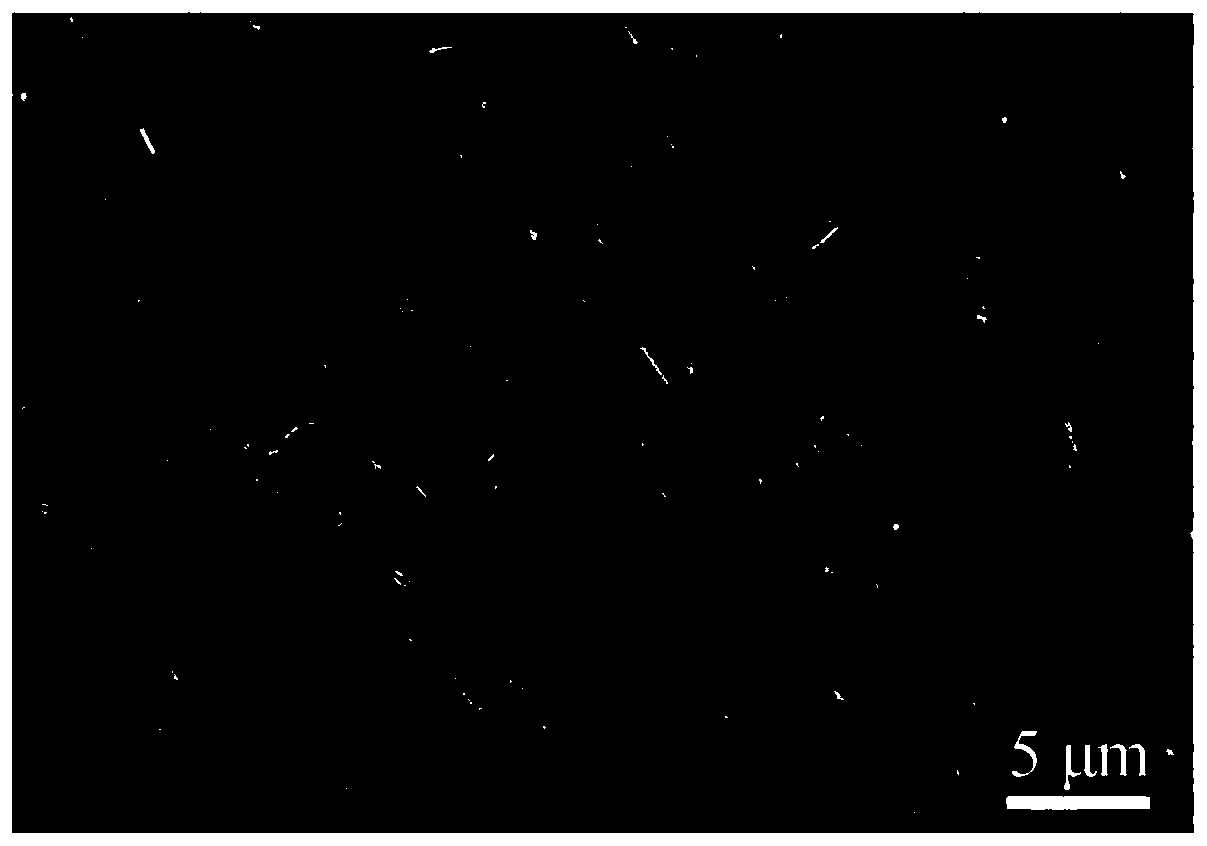

[0034] S2: Disperse 0.4g silicon carbide nanowires in 40ml NN dimethylformamide to obtain a silicon carbide nanowire dispersion with a concentration of 10mg / ml; (mass ratio of the polypropylene carbonate to the thermally conductive nanofiller 100:40)

[0035] S3: Add the silicon carbide nanowire dispersion obtained in step S2 to dispersion A at 2 drops per second, stir for 6 hours to obtain a silicon carbide nanowire-polymer mixture, and add the mixture to deionized water for precipitation To obtain a precipitate, which is washed with deionized water, filtered, dried, and thermoformed to obtain an initial composite material;

[0036] S4: Heat the initial composite material described in step S3 at 100°C for 2 minutes to soften it, and then stretch it to 3 times its initial length and drop to room temperature to fix the temp...

Embodiment 2

[0043] The difference between Embodiment 2 and Embodiment 1 is:

[0044] S1: 1g of polypropylene carbonate and 25ml of tetrahydrofuran were ultrasonically stirred for 2 hours to completely dissolve, and dispersion A was obtained.

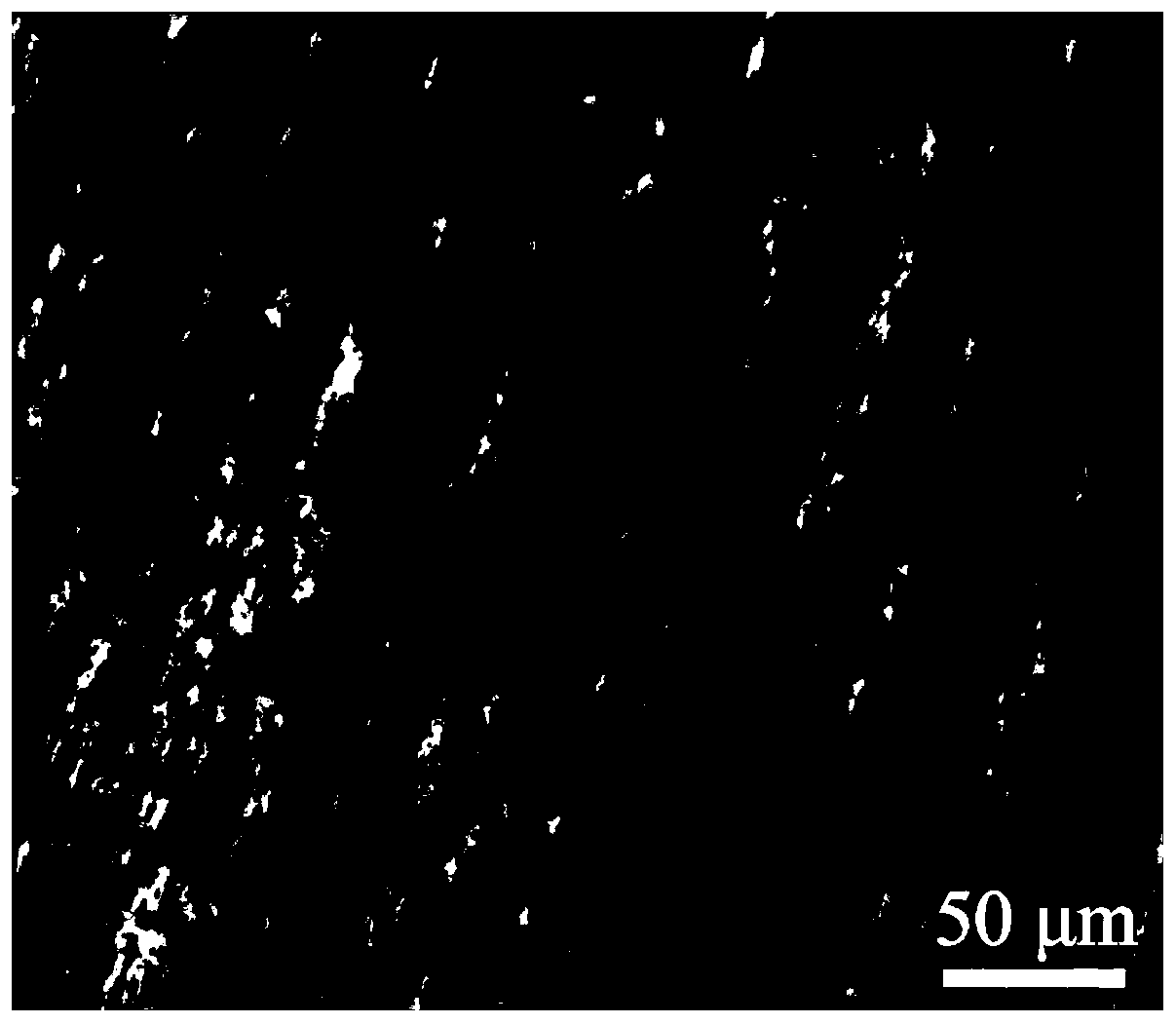

[0045] S2: Disperse 0.3 g of silver nanowires in 42 ml of tetrahydrofuran to obtain a silver nanowire dispersion with a concentration of 7 mg / ml. (The mass ratio of the polypropylene carbonate and the thermally conductive nano filler is 100:30)

[0046] S3: Add the silver nanowire dispersion obtained in step S2 to dispersion A at 2 drops per second, stir for 8 hours to obtain a silver nanowire-polymer mixture, and add the mixture to deionized water for precipitation to obtain Precipitation, where the precipitate is washed with deionized water, filtered, dried, and thermoformed to obtain a composite material;

[0047] S4: Heat the composite material described in step S3 at 60°C for 10 minutes to soften it, and then stretch it to twice its original length an...

Embodiment 3

[0052] The difference between Embodiment 3 and Embodiment 1 is:

[0053] S1: 3g of polypropylene carbonate and 30ml of dimethyl carbonate are ultrasonically stirred for 2 hours to completely dissolve, and dispersion A is obtained.

[0054] S2: Disperse 0.15g of boron nitride nanosheets in 37.5ml of dimethyl carbonate to obtain boron nitride nanosheets with a concentration of 4mg / ml. (The mass ratio of the polypropylene carbonate to the boron nitride nanosheet is 100:20)

[0055] S3: Add the boron nitride nanoplatelet dispersion obtained in step S2 dropwise to the dispersion A, stir for 10 hours to obtain a boron nitride nanoplatelet-polymer mixture, and add the mixture to deionized water to precipitate To obtain a precipitate, which is washed with deionized water, filtered, dried, and thermoformed to obtain a composite material;

[0056] S4: The composite material in step S3 is heated at 60°C for 5 minutes to soften, and then stretched to 1.5 times its original length and reduced to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com