Grafted antibacterial degradable fresh-keeping film, and preparation method and application thereof

A technology of film and branch type, which is applied in the field of grafted antibacterial and degradable fresh-keeping film and its preparation, and can solve problems such as food poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

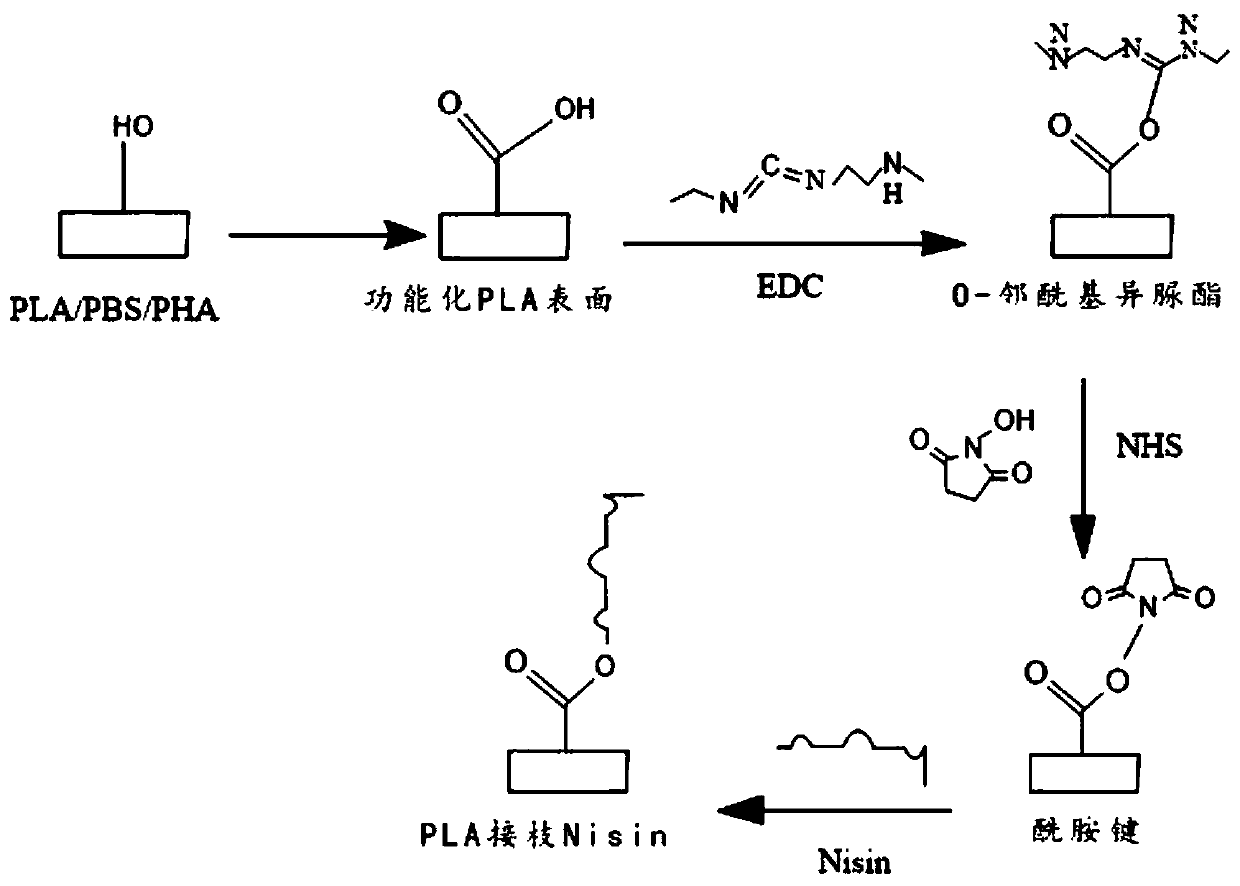

Method used

Image

Examples

Embodiment 1

[0046] PLA (2003D; Nature Works, USA), PHA (H2000; Samsung, South Korea) and PBS (1020MD; Japan Showa Denko Co., Ltd.) were thoroughly mixed according to the mass ratio of 4:3:3 and then extruded through twin-screws. The equipment is blended and extruded, cooled in a water tank, and cut to obtain composite masterbatches of uniform size. After drying in a blast drying oven at 60°C for 2 hours, the resin particles are cast into a film through a plastic extrusion device and a casting machine to obtain the described film. Among them, the temperatures in zone 1-7 of the twin-screw extrusion device are: 140°C, 160°C, 170°C, 175°C, 170°C, 170°C, 170°C, the screw speed is 50r / min, and the film thickness is controlled to be 45μm. The film is designated Film A.

Embodiment 2

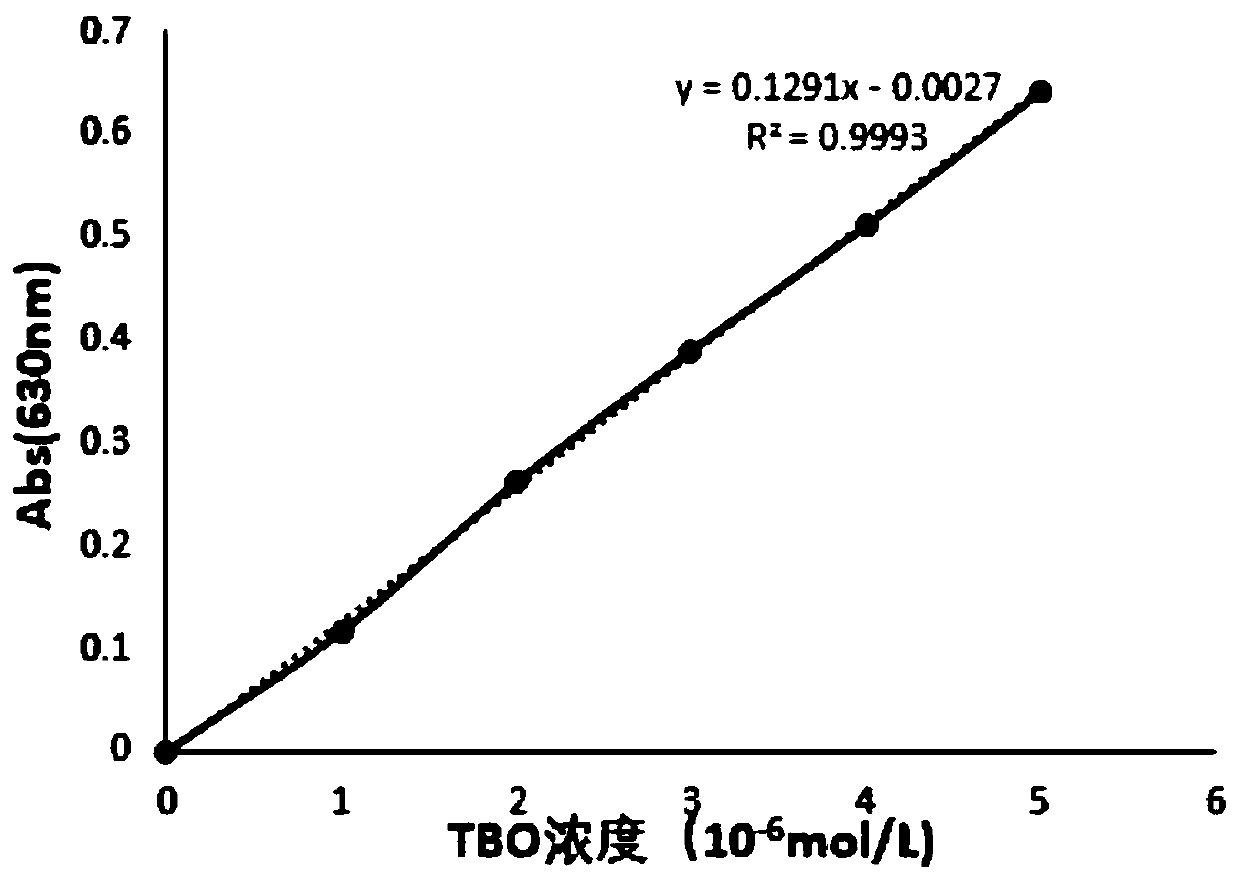

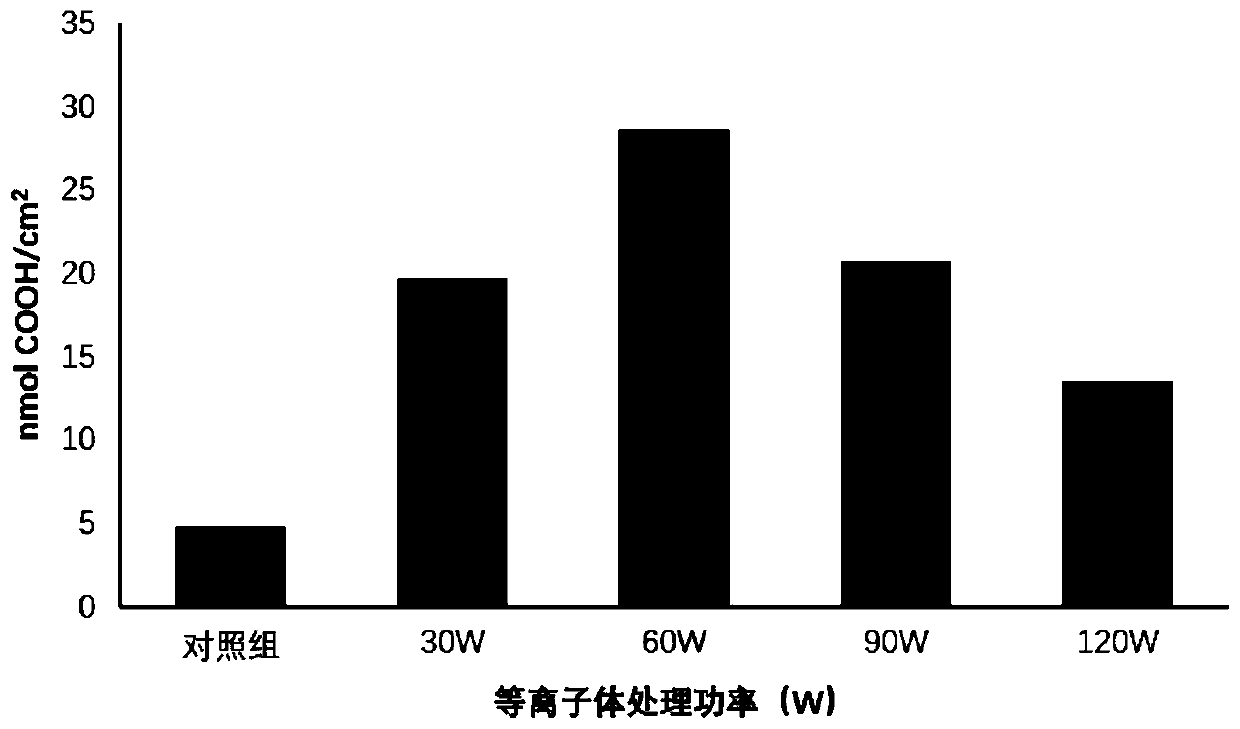

[0048] Film surface modification: The film A was ultrasonically cleaned with propanol, ethanol, and deionized water for 10 minutes, and then placed in a constant temperature blast drying oven at 35°C for 12 hours, and then the dried film was surfaced by a plasma processor at a constant speed. Modification, the power of the plasma processor is 30W, 60W, 90W, 120W, and the plasma speed is controlled at 8cm 2 / s. Depend on image 3 It can be seen that the amount of carboxyl groups on the surface of the film treated with 60W power is the highest, which is 28.6nmol COOH / cm 2 Afterwards, the films were all treated with a plasma power of 60W, and the film treated with a 60W plasma power was designated as film B, and the conjugated solution was prepared immediately.

[0049] Conjugate solution preparation: 5 x 10 -2 mol 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) and 1×10 -2 mol N-hydroxysuccinimide (NHS) was reacted in 1L 0.1mol / L buffer solution morpholineet...

Embodiment 3

[0052] Put film C into a beaker containing 1L nisin solution with a concentration of 5mg / mL, then place the beaker on a magnetic stirrer heated to 60°C and stir for 2h, and rinse the film with 1L deionized water after completion , then ultrasonically cleaned with deionized water for 10 minutes, and finally dried with clean air for 24 hours. Obtain the graft type antibacterial and degradable fresh-keeping film, which is denoted as food packaging film D. Nisin was purchased from Sinopharm Chemical Reagent Co., Ltd. Weigh 5g of nisin, dissolve it in 1L of distilled water at room temperature, stir to dissolve, and obtain a 5mg / L bacteriocin solution. The volume ratio of the single surface area of the film to the conjugated solution is 10cm 2 / mL, the volume ratio of the single surface area of the film to the nisin solution is 10cm 2 / mL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com