A preparation method of polytetrafluoroethylene@phenolic resin core-shell composite particles

A technology of polytetrafluoroethylene and composite particles, which is applied in the preparation of microspheres, microcapsule preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 A method for preparing polytetrafluoroethylene@phenolic resin core-shell composite particles, comprising the following steps:

[0030] (1) Mix 5 mL of polytetrafluoroethylene emulsion with a solid content of 60% and 58 mL of deionized water, and ultrasonically disperse for 10 minutes to prepare a polytetrafluoroethylene aqueous emulsion.

[0031] (2) Dissolve 0.03g of fluorine-containing surfactant in 10mL of deionized water, and disperse ultrasonically for 10min to obtain a surfactant dispersion.

[0032] (3) Mix the resorcinol aqueous solution with a mass concentration of 3.85%, the formaldehyde with a volume concentration of 5.66%, and the sodium hydroxide solution with a mass concentration of 0.3% in an equal volume ratio (10mL) to obtain a mixed solution.

[0033] (4) After mixing the polytetrafluoroethylene aqueous emulsion and the dispersion of the surfactant FC-134, after mechanically stirring for 30 minutes, inject the mixed solution into the constant...

Embodiment 2

[0043] Example 2 A method for preparing polytetrafluoroethylene@phenolic resin core-shell composite particles, comprising the following steps:

[0044] (1) Mix 3 mL of polytetrafluoroethylene emulsion with a solid content of 60% and 40 mL of deionized water, and ultrasonically disperse for 10 minutes to prepare a polytetrafluoroethylene aqueous emulsion.

[0045] (2) Dissolve 0.01 g of fluorine-containing surfactant in 10 mL of deionized water, and disperse ultrasonically for 10 min to obtain a surfactant dispersion.

[0046] (3) Mix the resorcinol aqueous solution with a mass concentration of 3.85%, the formaldehyde with a volume concentration of 5.66%, and the sodium hydroxide solution with a mass concentration of 0.3% in an equal volume ratio (10mL) to obtain a mixed solution.

[0047] (4) After mixing the polytetrafluoroethylene aqueous emulsion and the dispersion liquid of the surfactant, after mechanically stirring for 30 minutes, inject the mixed solution into the const...

Embodiment 3

[0049] Example 3 A method for preparing polytetrafluoroethylene@phenolic resin core-shell composite particles, comprising the following steps:

[0050] (1) Mix 5 mL of polytetrafluoroethylene emulsion with a solid content of 60% and 58 mL of deionized water, and ultrasonically disperse for 10 minutes to prepare a polytetrafluoroethylene aqueous emulsion.

[0051] (2) Dissolve 0.03g of fluorine-containing surfactant in 10mL of deionized water, and disperse ultrasonically for 10min to obtain a surfactant dispersion.

[0052] (3) Mix the resorcinol aqueous solution with a mass concentration of 3.85%, the formaldehyde with a volume concentration of 5.66%, and the sodium hydroxide solution with a mass concentration of 0.3% in an equal volume ratio (10mL) to obtain a mixed solution.

[0053] (4) After mixing the polytetrafluoroethylene aqueous emulsion and the dispersion liquid of the surfactant, after mechanically stirring for 30 minutes, inject the mixed solution into the constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

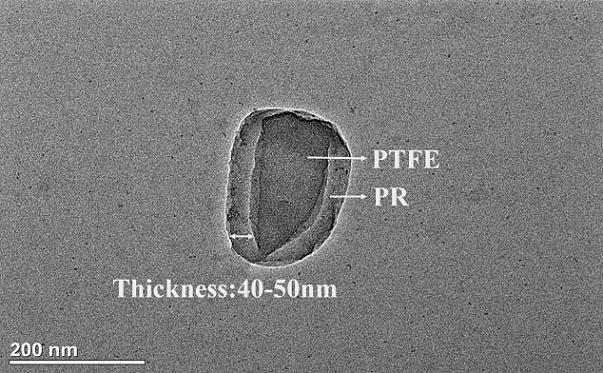

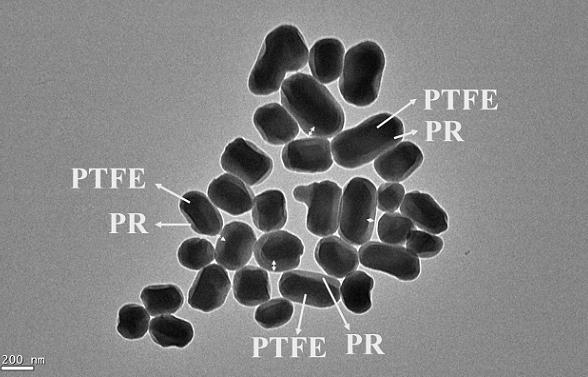

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com