Transmission electron microscope carrier net capable of being produced in batches and preparation method of transmission electron microscope carrier net

A technology for transmission electron microscopy and mass production, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of blank and high cost, and achieve the effect of high yield, low cost and low technical level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

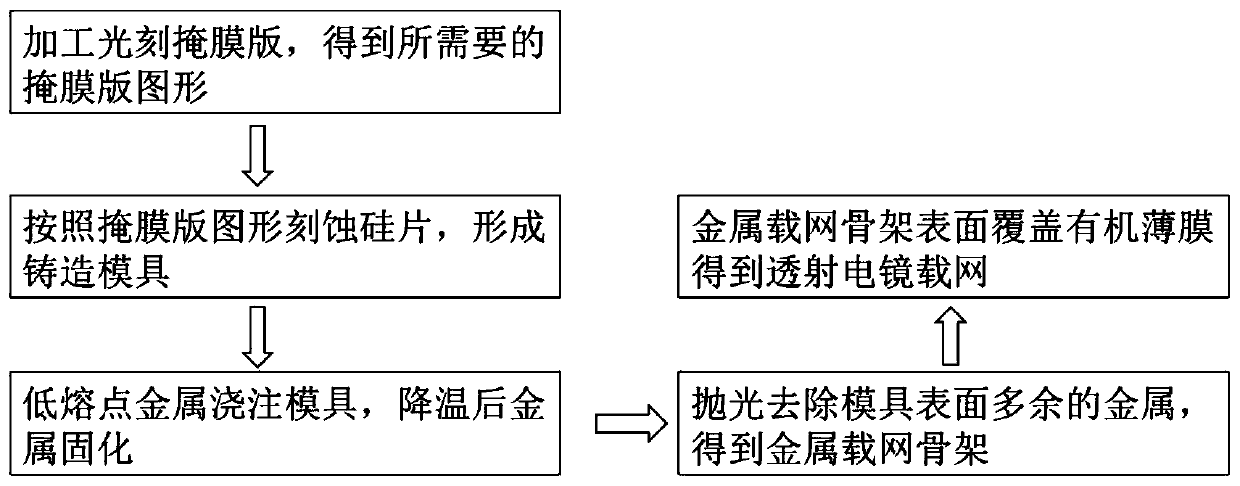

[0032] A preparation method of a mass-produced transmission electron microscope grid, the method comprising the following steps:

[0033] 1) Design and process the photolithographic mask according to the requirements of the transmission electron microscope grid, and obtain a mask pattern with a diameter of 3 mm. The mesh number in the pattern is 200 mesh, and the shape of the mesh is a square hole;

[0034] 2) transfer the mask pattern to the silicon wafer by photolithography process, and etch the mask pattern into the silicon wafer by etching process to form a casting mold, wherein the etching depth is 20 μm;

[0035] 3) Heat the casting mold to 100°C, then melt the low-melting metal bismuth-tin alloy and pour it into the mold, and the metal solidifies after cooling down to room temperature;

[0036] 4) Polishing to remove excess metal on the upper surface after the casting mold is filled, and then use adhesive tape to peel off the cast metal grid skeleton from the casting mo...

Embodiment 2

[0040] A preparation method of a mass-produced transmission electron microscope grid, the method comprising the following steps:

[0041] 1) Design and process the photolithographic mask according to the requirements of the transmission electron microscope grid, and obtain a mask pattern with a diameter of 3 mm. The mesh number in the pattern is 600 mesh, and the mesh shape is a hexagonal hole;

[0042] 2) Transfer the mask pattern to the silicon wafer by photolithography process, and etch the mask pattern into the silicon wafer by etching process to form a casting mold, wherein the etching depth is 30 μm;

[0043] 3) Heat the casting mold to 70°C, then melt the low-melting-point metal tin-indium-bismuth alloy and pour it into the mold, and the metal solidifies after cooling down to room temperature;

[0044] 4) Polishing to remove excess metal on the upper surface after the casting mold is filled, and then use adhesive tape to peel off the cast metal grid skeleton from the ca...

Embodiment 3

[0048] A preparation method of a mass-produced transmission electron microscope grid, the method comprising the following steps:

[0049] 1) Design and process the photolithographic mask according to the requirements of the transmission electron microscope grid, and obtain a mask pattern with a diameter of 3 mm. The mesh number in the pattern is 1000 mesh, and the shape of the mesh is a round hole;

[0050] 2) Transfer the mask pattern to the silicon wafer by photolithography process, and etch the mask pattern into the silicon wafer by etching process to form a casting mold, wherein the etching depth is 40 μm;

[0051] 3) Heat the casting mold to 150°C, then melt the low-melting-point metal lead-tin alloy and pour it into the mold, and the metal solidifies after cooling down to room temperature;

[0052] 4) Polishing to remove excess metal on the upper surface after the casting mold is filled, and then use adhesive tape to peel off the cast metal grid skeleton from the casting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com