Preparation method of high-temperature-resistant red polyimide film

A technology of polyimide film and high temperature resistance, which is applied in the field of preparation of high temperature resistant red polyimide film. Effect of coloring effect, reduction of thermal decomposition rate, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

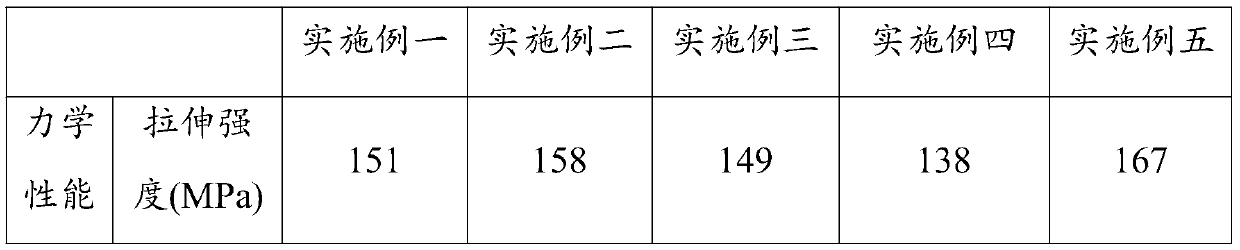

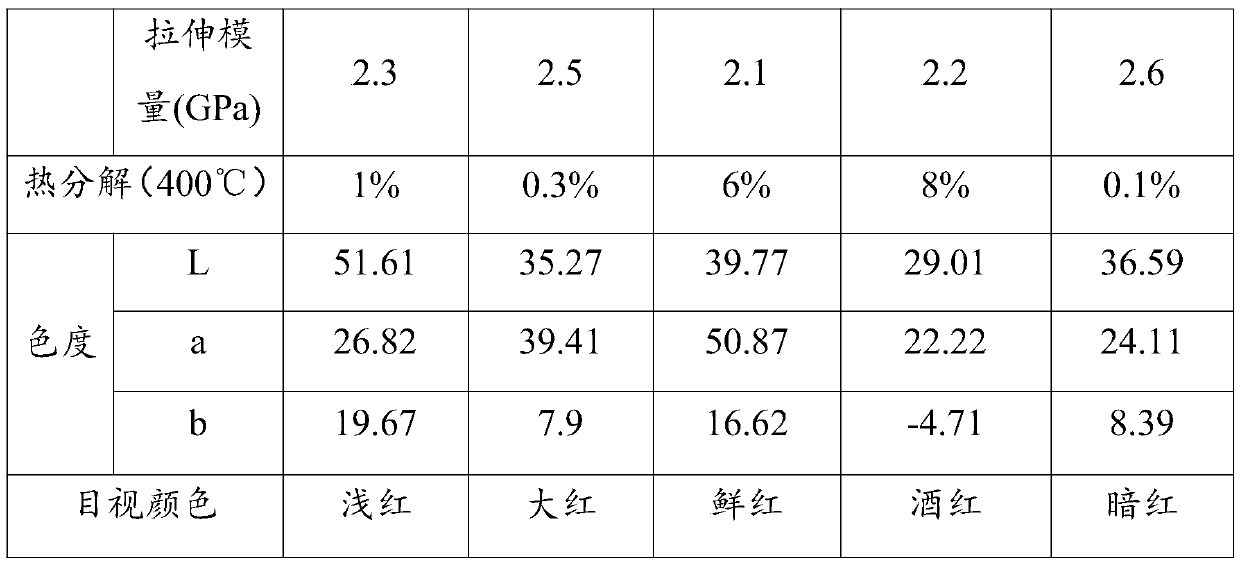

Examples

Embodiment 1

[0027] The preparation method of the red polyimide film provided by the invention comprises the use of diketopyrrolopyrrole organic red pigment DPP red, the heat stabilizer is p-phenol, and the coupling agent is γ-aminopropyltriethoxysilane , the aromatic diamine monomer is 4,4'-diaminodiphenyl ether, the aromatic dianhydride is pyromellitic dianhydride, and the weight ratio of the organic red pigment in the polyamic acid is 0.6%. Phenol accounts for 5% of the organic red pigment, and γ-aminopropyltriethoxysilane accounts for 1% of the organic red pigment.

[0028] Treat p-phenol and γ-aminopropyltriethoxysilane in N-methylpyrrolidone with ultrasonic stirring at room temperature for 5 minutes, then add organic red pigment and ultrasonically stir for 60 minutes, so that the red pigment is evenly dispersed in N-methylpyrrolidone pyrrolidone solvent. In the remaining dimethylformamide, add 4,4'-diaminodiphenyl ether, stir to dissolve, add the treated red pigment solution into th...

Embodiment 2

[0030] The preparation method of the red polyimide film provided by the invention comprises the use of organic red pigment DPP red, the heat stabilizer is p-phenol, the coupling agent is γ-aminopropyltriethoxysilane, aromatic diamine mono The body is 4,4'-diaminodiphenyl ether, the aromatic dianhydride is pyromellitic dianhydride, the weight ratio of the organic red pigment in the polyamic acid is 4%, and the para-phenol occupies 4% of the organic red pigment. 10%, γ-aminopropyltriethoxysilane accounts for 5% of the organic red pigment.

[0031] Treat p-phenol and γ-aminopropyltriethoxysilane in N-methylpyrrolidone with ultrasonic stirring at room temperature for 5 minutes, then add organic red pigment and ultrasonically stir for 60 minutes, so that the red pigment is evenly dispersed in N-methylpyrrolidone pyrrolidone solvent. In the remaining dimethylformamide, add 4,4'-diaminodiphenyl ether, stir to dissolve, add the treated red pigment solution into the dissolved amine so...

Embodiment 3

[0033] The preparation method of the red polyimide film provided by the invention comprises the use of an azo organic red pigment permanent red FR, the heat stabilizer is p-phenol, the coupling agent is γ-aminopropyltriethoxysilane, aromatic The aromatic diamine monomer is 4,4'-diaminodiphenyl ether, the aromatic dianhydride is pyromellitic dianhydride, the organic red pigment accounts for 3% by weight in the polyamic acid, and the para-phenol occupies 5% of the organic red pigment, and γ-aminopropyltriethoxysilane accounts for 1% of the organic red pigment.

[0034] Treat p-phenol and γ-aminopropyltriethoxysilane in dimethylacetamide with ultrasonic stirring at room temperature for 5 minutes, then add organic red pigment and ultrasonically stir for 60 minutes, so that the red pigment is evenly dispersed in N-methyl pyrrolidone solvent. In the remaining dimethylformamide, add 4,4'-diaminodiphenyl ether, stir to dissolve, add the treated red pigment solution into the dissolved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com