A kind of method for preparing boron phosphide with high thermal conductivity by molten salt method

A technology of high thermal conductivity and molten salt method, applied in chemical instruments and methods, heat exchange materials, inorganic chemistry, etc., can solve the problems of difficult control of product morphology, lower BP thermal conductivity, high heat risk, etc., and achieve BP composition Uniform and single, good crystal morphology, and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a method for preparing boron phosphide with high thermal conductivity by molten salt method, which is carried out in the following steps:

[0031] 1. Clean the BN crucible and ultrasonically treat it, then dry it for later use; mix 1g of magnesium powder, 1g of boron phosphate and 1g of sodium chloride evenly, and place it in the crucible;

[0032] 2. Put the BN crucible in step 1 into the reaction furnace, pass in Ar gas and raise the temperature to 750°C at a heating rate of 3°C / min and keep it for 1h;

[0033] 3. Take the sample obtained in step 2 out of the reactor, soak it in concentrated hydrochloric acid at room temperature for 30 minutes, heat it in a water bath to 60°C for 30 minutes, then wash it with deionized water until PH = 7, and dry it to obtain BP.

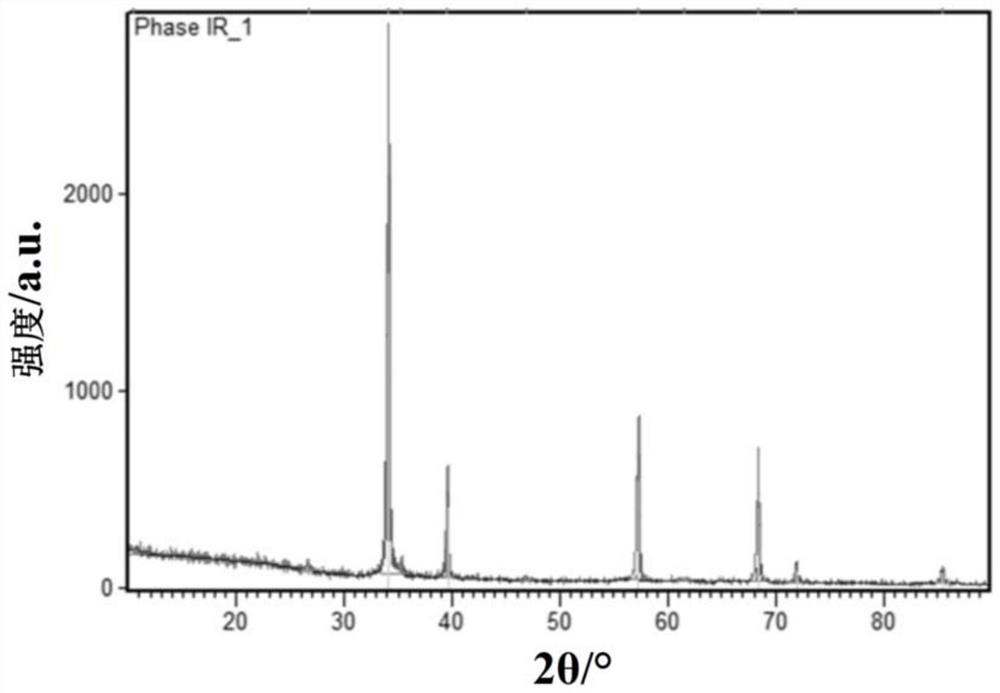

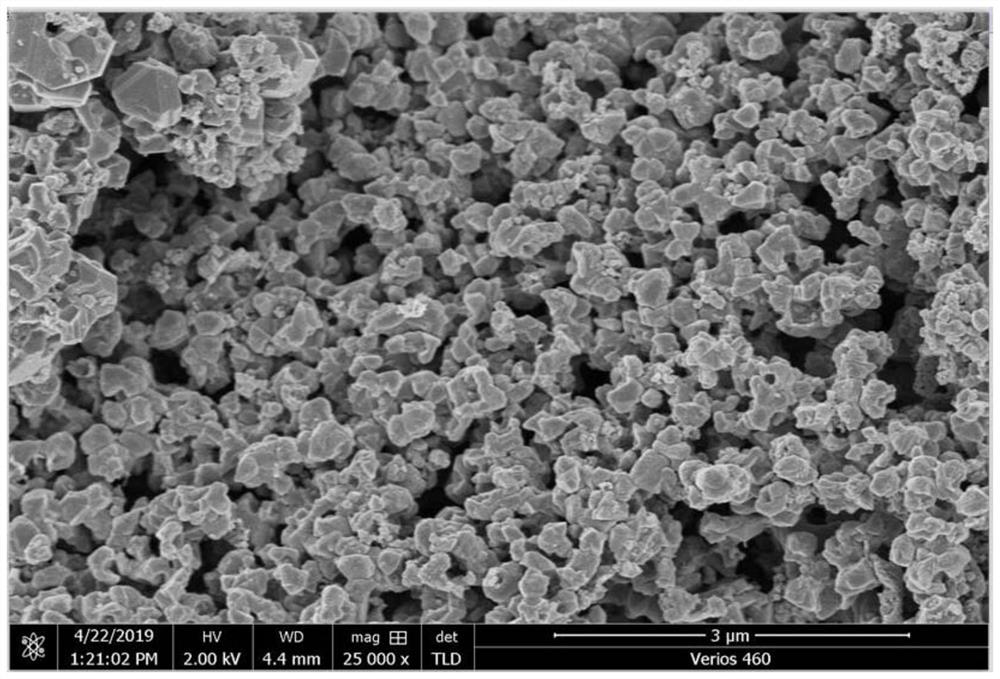

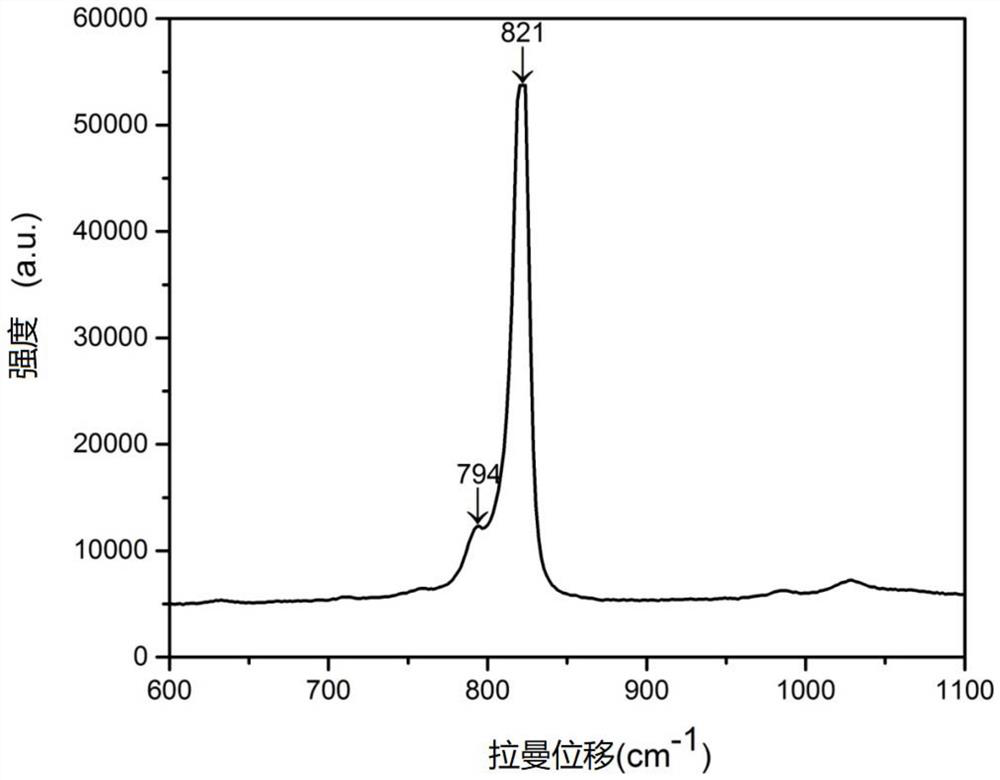

[0034] see figure 1 As shown in the xrd diagram, the chemical composition of the prepared BP is uniform, without B 12 P 2 The formation of other impurities, and the BP peak inten...

Embodiment 2

[0038] In this embodiment, a method for preparing boron phosphide with high thermal conductivity by molten salt method is carried out according to the following steps:

[0039] 1. Clean the BN crucible and ultrasonically treat it, then dry it for later use; mix 2g of magnesium powder, 1g of boron phosphate and 2g of sodium chloride evenly, and place them in the crucible;

[0040]2. Put the BN crucible in step 1 into the reaction furnace, feed Ar gas and raise the temperature to 850°C at a heating rate of 4°C / min for 3 hours;

[0041] 3. Take the sample obtained in step 2 out of the reaction kettle, soak it in concentrated hydrochloric acid at room temperature for 50 minutes, and heat it in a water bath to 60°C for 50 minutes, then wash it with deionized water until PH=7, and dry it to obtain BP.

Embodiment 3

[0043] In this embodiment, a method for preparing boron phosphide with high thermal conductivity by molten salt method is carried out according to the following steps:

[0044] 1. Clean the BN crucible and ultrasonically treat it, then dry it for later use; mix 3g of magnesium powder, 1g of boron phosphate and 1g of potassium chloride evenly, and place them in the crucible;

[0045] 2. Put the BN crucible in step 1 into the reaction furnace, feed Ar gas and raise the temperature to 850°C at a heating rate of 5°C / min for 6 hours;

[0046] 3. Take the sample obtained in step 2 out of the reactor, soak it in concentrated hydrochloric acid at room temperature for 70 minutes, heat it in a water bath to 60°C for 70 minutes, then wash it with deionized water until PH=7, and dry it to obtain BP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com