Die-casting aluminum alloy electroplating pretreatment process

A technology of electroplating pretreatment and casting aluminum alloy, which is applied in the direction of metal material coating process, etc., can solve the problems of affecting the electroplating process, low work efficiency, high labor cost, etc., and achieve the goal of saving raw material costs, reducing equipment investment, and reducing labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

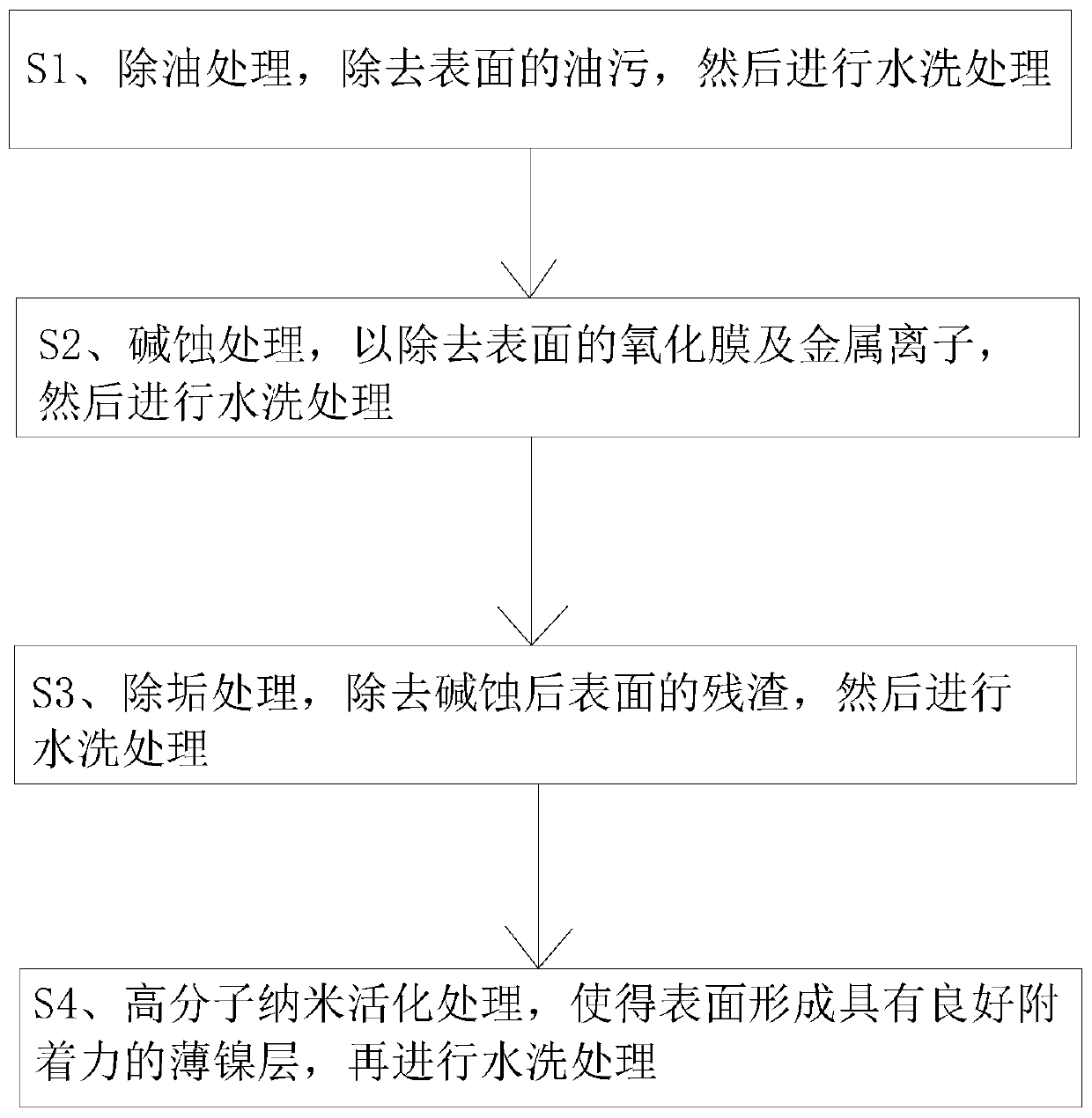

[0018] see figure 1 As shown, the present invention relates to a pretreatment process for die-casting aluminum alloy electroplating, comprising the following steps:

[0019] S1, degreasing treatment, use a degreasing agent to perform degreasing treatment on the die-casting aluminum alloy parts, remove the oil stains on the surface, and then perform water washing treatment;

[0020] S2. Alkali etching treatment, the die-casting aluminum alloy parts are placed in an alkaline solution for alkaline etching treatment to remove the oxide film and metal ions on the surface, and then washed with water;

[0021] S3, descaling treatment, using a descaling agent to perform descaling treatment on the die-casting aluminum alloy parts, remove the residue on the surface after alkali corrosion, and then perform water washing treatment;

[0022] S4. Activation treatment. Place the die-casting metal alloy parts in an activation solution with a pH value of 5.5-6.6 at room temperature for 10-30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com