A kind of preparation method of natural graphite slurry

A technology of natural graphite and slurry, which is applied in the direction of graphite, conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, etc., can solve the unstable batch performance of graphite negative electrodes, poor cycle performance of graphite negative electrodes, Problems such as particle morphology and particle size distribution are not uniform, so as to avoid the settlement of large particles and reduce the effect of edges and corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

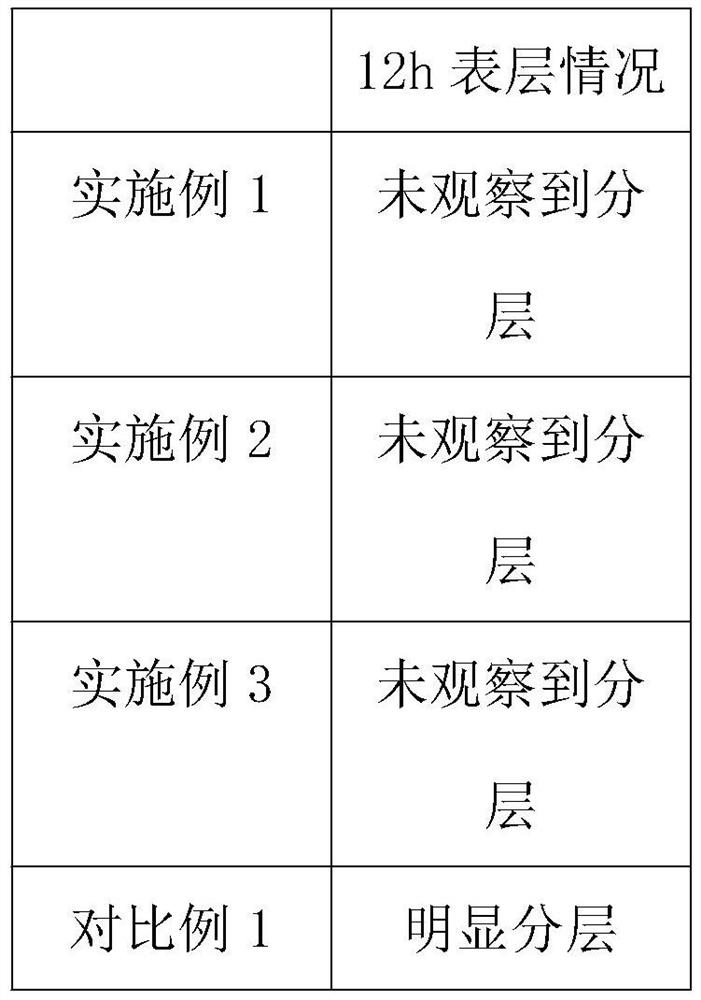

Examples

Embodiment 1

[0030] 1) The natural graphite material is sequentially passed through a screen with a mesh diameter of 25 microns, 20 microns, 17 microns and 12 microns, and the natural graphite raw materials are separated according to the particle size range, and the natural graphite with a particle size distribution between 20-25 microns Ink is used as the first material, natural graphite with particle size distribution between 17-20 microns is used as the second material, natural graphite with particle size distribution between 12-17 microns is used as the third material, and particle size distribution is between 12 Natural graphite below micron is used as the fourth material;

[0031] 2) The first material is sieved under high pressure, and the sieve size is 28 microns;

[0032] 3) the second material is sieved under high pressure, and the sieve size is 22 microns;

[0033] 4) The third material is sieved under high pressure, and the sieve size is 18 microns;

[0034] 5) The fourth mat...

Embodiment 2

[0041] 1) The natural graphite material is sequentially passed through a screen with a mesh diameter of 25 microns, 20 microns, 17 microns and 12 microns, and the natural graphite raw materials are separated according to the particle size range, and the natural graphite with a particle size distribution between 20-25 microns Ink is used as the first material, natural graphite with particle size distribution between 17-20 microns is used as the second material, natural graphite with particle size distribution between 12-17 microns is used as the third material, and particle size distribution is between 12 Natural graphite below micron is used as the fourth material;

[0042] 2) The first material is sieved under high pressure, and the sieve size is 30 microns;

[0043] 3) the second material is sieved under high pressure, and the sieve size is 24 microns;

[0044] 4) The third material is sieved under high pressure, and the sieve size is 20 microns;

[0045] 5) The fourth mat...

Embodiment 3

[0052] 1) The natural graphite material is sequentially passed through a screen with a mesh diameter of 25 microns, 20 microns, 17 microns and 12 microns, and the natural graphite raw materials are separated according to the particle size range, and the natural graphite with a particle size distribution between 20-25 microns Ink is used as the first material, natural graphite with particle size distribution between 17-20 microns is used as the second material, natural graphite with particle size distribution between 12-17 microns is used as the third material, and particle size distribution is between 12 Natural graphite below micron is used as the fourth material;

[0053] 2) The first material is sieved under high pressure, and the sieve size is 29 microns;

[0054] 3) the second material is sieved under high pressure, and the sieve size is 23 microns;

[0055] 4) The third material is sieved under high pressure, and the sieve size is 19 microns;

[0056] 5) The fourth mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com