Double-sided anti-reflection film lens coating processing technology

A technology of anti-reflection film and double-sided reflection, applied in optical components, optics, instruments, etc., can solve problems such as difficulty, visual field ripple, wavelength shift, and reduce reflectivity, etc., to achieve low production cost, film The effect of excellent firmness and excellent firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

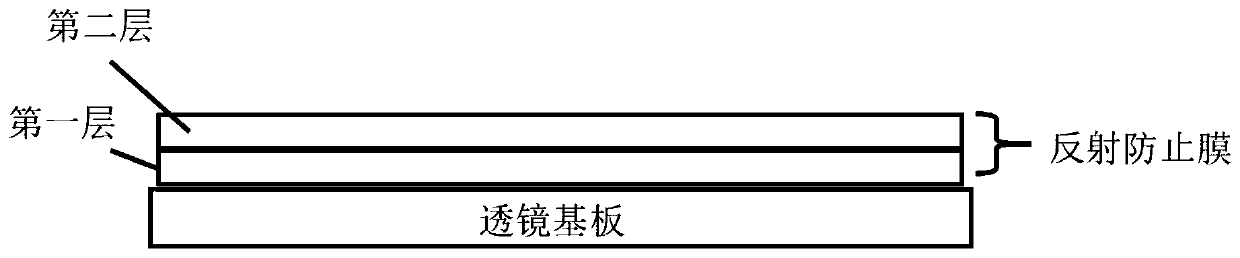

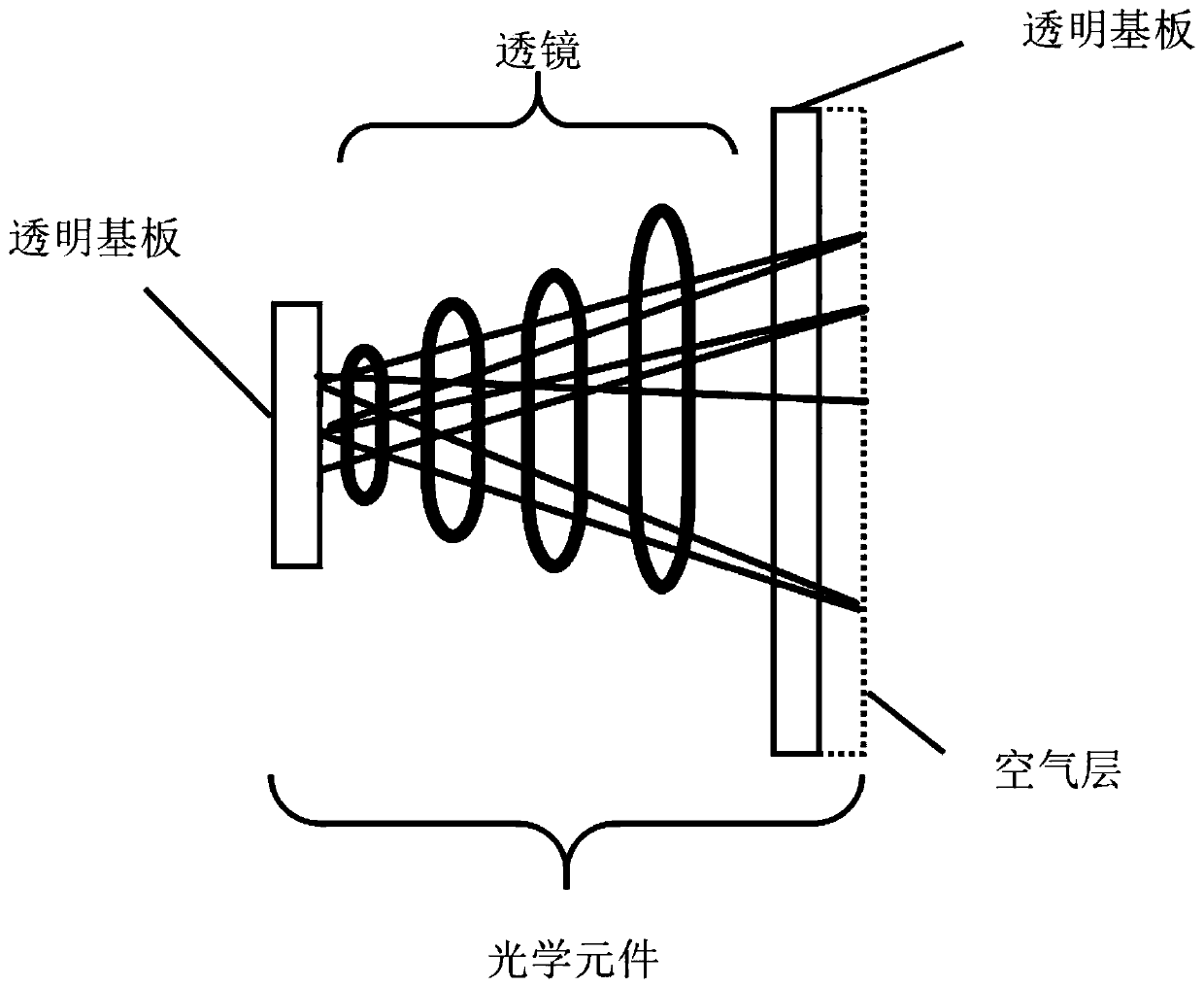

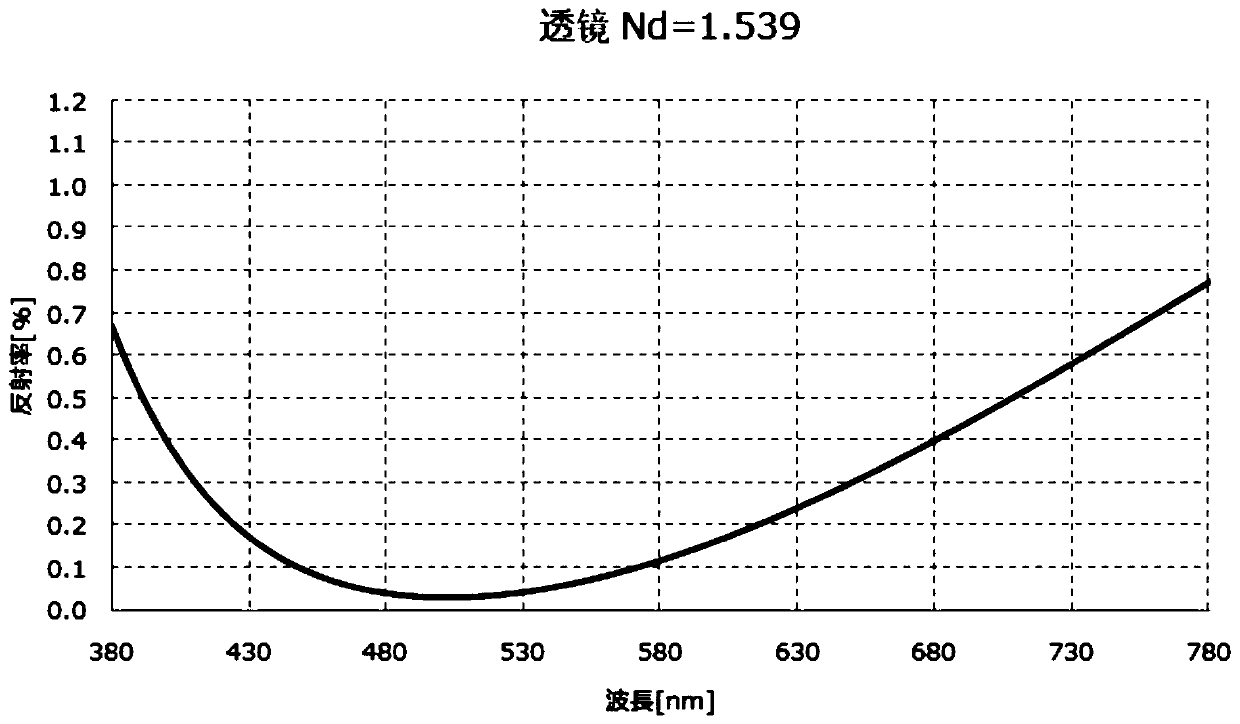

[0041] Embodiment: a kind of double-sided anti-reflection film lens coating process, such as Figure 1-5 shown, including the following steps:

[0042] S1: Fix the lens on the fixture;

[0043] (1) The base is rotated by the working motor, and the worktable and the base are fixed;

[0044] (2) The lens is placed on the suction hole groove, and the size of the suction hole groove is set according to the size of the lens. After adjustment, the edge of the lens is just embedded in the suction hole groove;

[0045] (3) The working table adopts the principle of vacuum adsorption, so that the lens is firmly adsorbed on the suction hole groove, and the height of the suction hole groove is controlled between 5mm-10mm;

[0046] S2: Drop ink on the surface of the lens so that the surface of the lens is completely covered by ink;

[0047] S3: Control the rotation speed by the motor to maintain the thickness of the coating layer on the surface of the lens at high speed and uniformity; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical film thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com