Efficient sewage treatment system

A technology of sewage treatment system and sewage treatment tank, which is applied in water/sewage treatment, light water/sewage treatment, water/sewage treatment equipment, etc. Sewage treatment components clogging and other problems, to achieve the effect of reducing workload, scientific and reasonable structure, and reducing the possibility of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

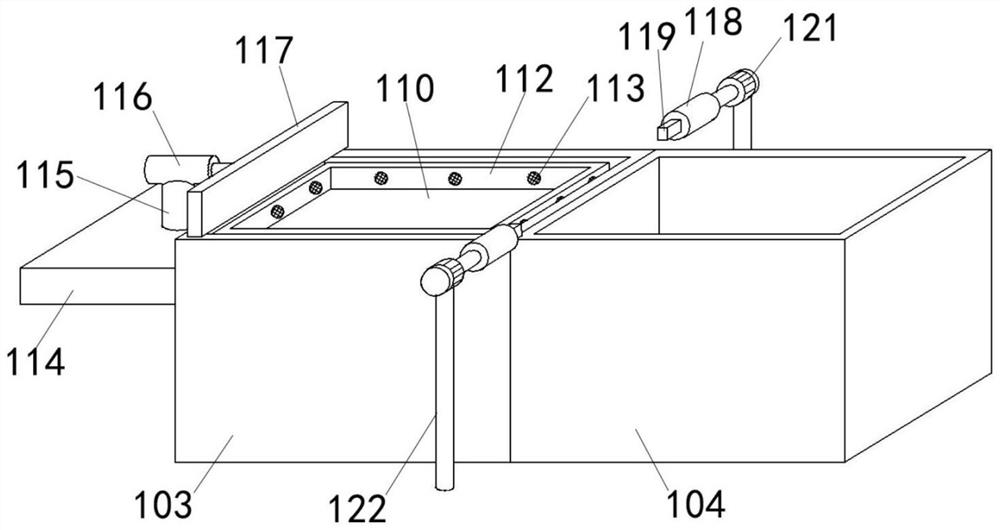

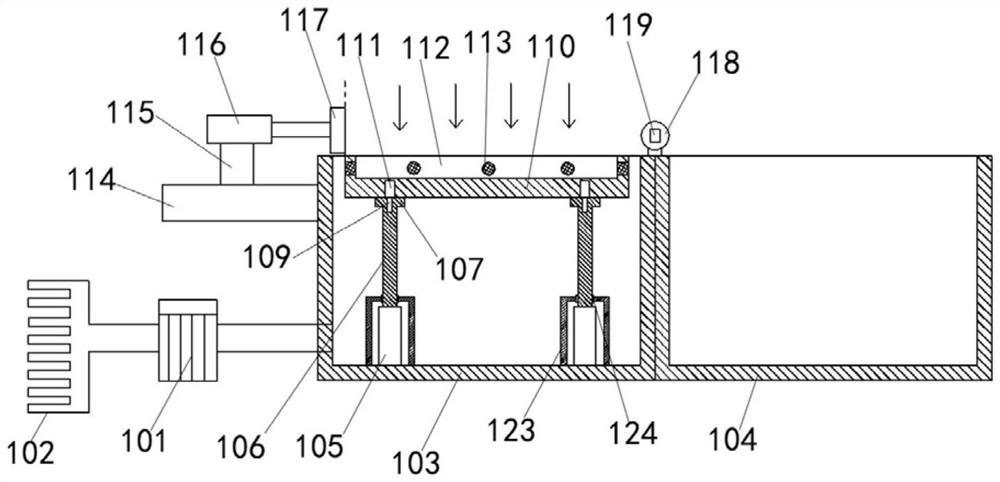

[0040] Example: such as Figure 1-5 As shown, a high-efficiency sewage treatment system includes a floating object cleaning device 100 and a visible light catalytic treatment device 200. After the floating object is cleaned by the floating object cleaning device 100, the sewage is sent to the visible light catalytic processing system by a booster pump 101 through each branch pipe 102. The sewage treatment tank 5 of the treatment device 200, the floating object cleaning device 100 includes a sewage transfer tank 103 and a floating object collection tank 104, at least two pneumatic cylinders 105 are fixedly connected to the bottom of the sewage transfer tank 103, and the output shaft 106 upper end of each pneumatic cylinder The contact plate 107 is fixed, and the contact plate 107 is provided with a positioning hole 109 for the insertion of the positioning shaft 108. The positioning shaft 108 is driven by the first electric telescopic rod 111 embedded in the collecting plate 110;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com