A construction method of continuous composite beam

A construction method and technology of composite beams, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of easy cracking, high stress, low service life, etc., to increase crack resistance, increase service life, prevent Effect of quality accident or safety accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

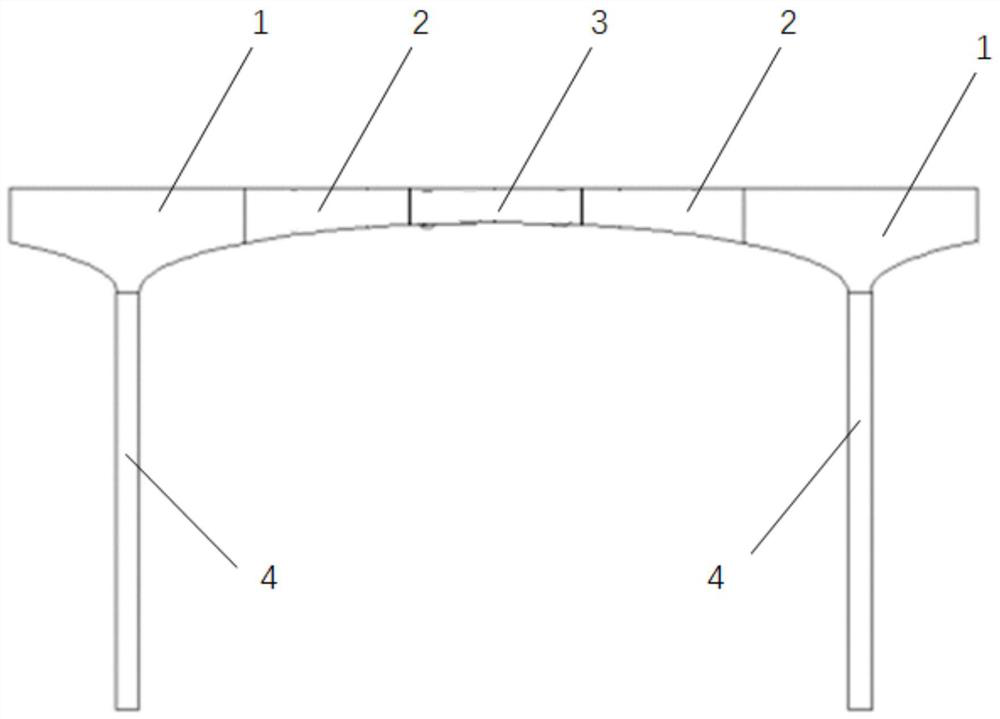

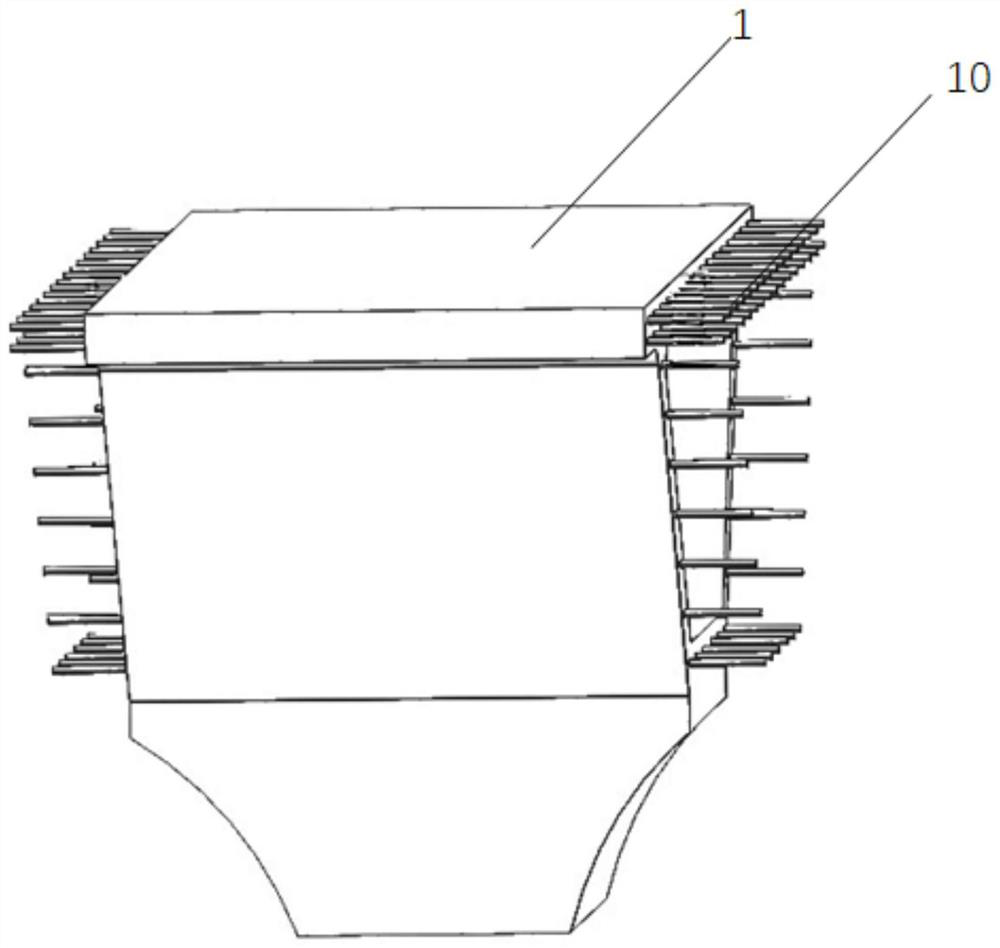

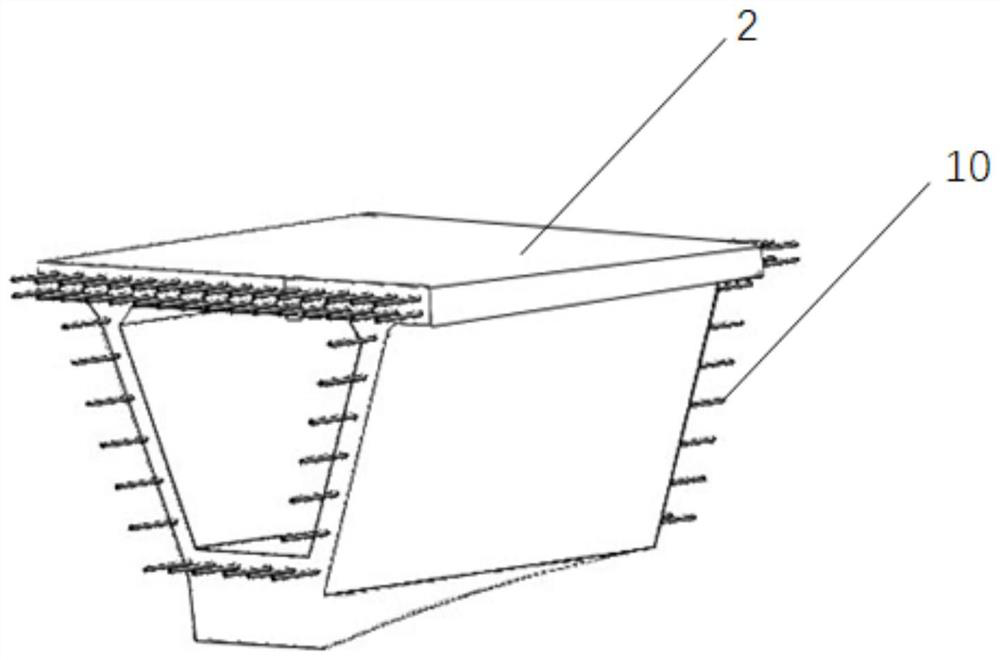

[0060] A construction method for a continuous composite beam, comprising the following steps:

[0061] Step [1]: Make prefabricated bridge pieces. In this embodiment, a total of three specifications of prefabricated bridge pieces are provided, namely No. 1 prefabricated bridge piece 1, No. 2 prefabricated bridge piece 2 and No. ③ prefabricated bridge piece 3, and the size of the prefabricated bridge piece is set according to the specific conditions of the bridge. The concrete pouring process is set in the beam prefabrication field for industrial production, and the prefabricated bridge pieces are constructed using the pretensioning method. In this embodiment, the diameter of the steel bar of the prefabricated bridge piece is 20cm, and 35cm of prestressed tendons 10 are reserved on the left and right sides. Leave 30cm ~ 40cm of prestressed tendons. The prestressed tendons of the bridge deck are provided with two layers, and the prestressed tendons of the lower layer are arran...

Embodiment 2

[0069] This embodiment is basically the same as the technical solution of the first embodiment, the difference is that between steps [6] and [7], a link of applying adhesive to the cross-section of the prefabricated bridge piece is added. Remove the loose concrete at the section of the prefabricated bridge piece, remove impurities such as oil stains and dust, and dry the concrete at the section of the prefabricated bridge piece, and then apply adhesive on the section of the prefabricated bridge piece. The adhesive used in this embodiment The invention is a chemical concrete mixture made by mixing epoxy resin and cement, and belongs to the commonly used binder in the prior art. The adhesive is applied evenly, the thickness is controlled between 0.5mm and 1mm, and the bonding strength between the adhesive and the concrete is greater than that of the concrete. In order to stabilize the adhesive on the section of the prefabricated bridge sheet, after applying the adhesive, apply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com