Replacement process for lifting steel wire rope of vertical shaft multi-rope friction lifter

A technology of friction hoist and steel wire rope, which is applied in the direction of lifting equipment, transportation and packaging in mines, to achieve the effects of saving construction time, light weight and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

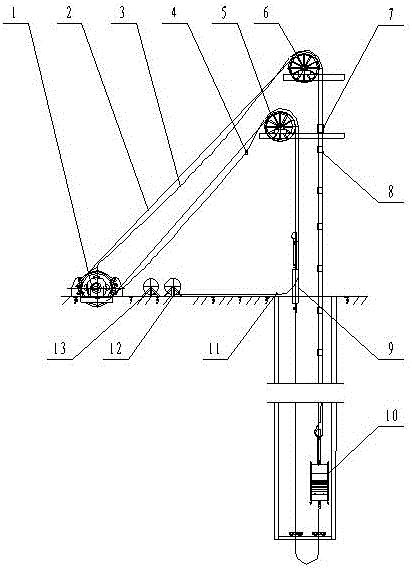

[0030] Usually, the balance weight 9 and the cage 10 are suspended by four old ropes 2 side by side. In order to ensure safety, the old ropes 2 can be quickly replaced, and four new ropes 3 can be carried at the same time; the new ropes 3 are connected with the wedge-shaped rope loop. When , the outermost two wedge-shaped rope loops can be connected first, and then the middle two wedge-shaped rope loops can be connected.

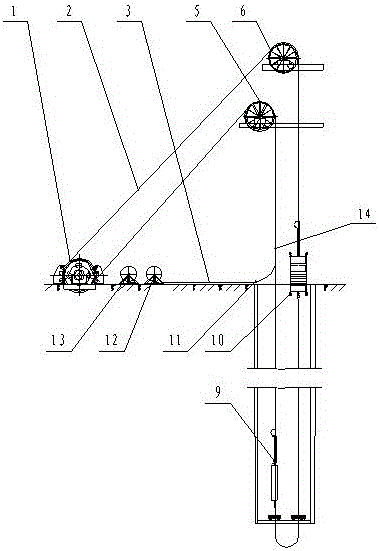

[0031] like figure 1 and Image 6 As shown, first place the new rope reel 12 and the old rope reel 13 at the appropriate position on the side of the counterweight 9 at the upper wellhead, stop the cage 10 at the upper wellhead position, and pass the head of the new rope 3 on the upper wellhead through the side of the counterweight 9 The guide wheel 11 is used to connect the traction rope 14 with the new rope 3 and the old rope 2 by the method of reverse pick-up to complete the preparation work.

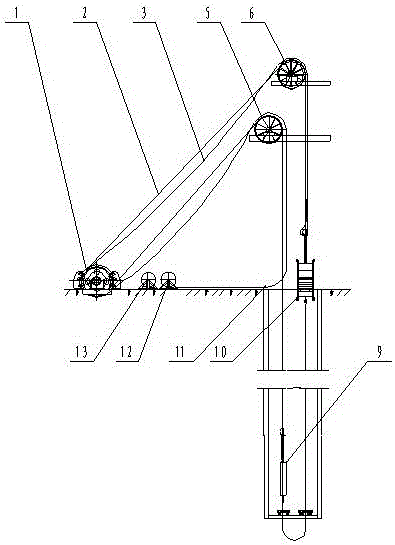

[0032] like figure 2 As shown, the four new ropes 3 are br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com