Long-acting antibacterial fabric rich in silver ion fibers and preparation method of long-acting antibacterial fabric rich in silver ion fibers

An antibacterial fabric, silver ion technology, applied in the direction of cellulose/protein conjugated rayon, fiber chemical characteristics, chemical method to produce bast fiber, etc. problem, to achieve the best antibacterial performance, antibacterial long-term stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

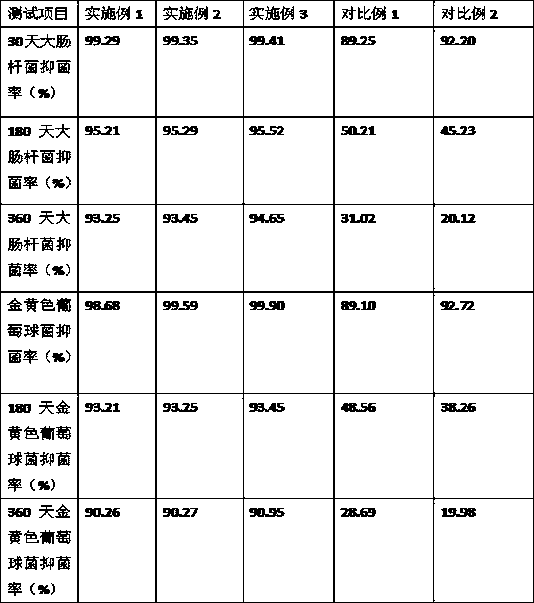

Examples

preparation example Construction

[0048] Preparation of pretreated oak bark fibers:

[0049] (1) Mix oak bark and citric acid solution with a mass fraction of 10% in a mass ratio of 1:10, put them into a beaker, heat up to 60-70°C, heat-preserve and soak for 1-2 hours, and the soaking process ends Finally, take out the oak bark of pickling treatment;

[0050] (2) After the acid leached oak bark is naturally dried, beat it repeatedly with a wooden hammer for 40-50 minutes, rinse it with water for 3-5 times, put it in an oven, heat it up to 100-110°C, and dry it for 10-50 minutes. 12h, obtain the degummed oak bark fiber;

[0051] (3) Prepare an aqueous solution of N-methylmorpholine with a mass fraction of 30%, mix the aqueous solution of N-methylmorpholine with the above-mentioned degummed oak bark fiber at a mass ratio of 15:1, and put it into an ultrasonic oscillator, Ultrasonic oscillation reaction at a frequency of 35-40 kHz for 1-2 hours, and pretreated oak bark fibers were obtained after the reaction; ...

example 1

[0061] Preparation of pretreated oak bark fibers:

[0062] (1) Mix oak bark and citric acid solution with a mass fraction of 10% in a mass ratio of 1:10, put them into a beaker, heat up to 60°C, and soak for 1 hour. After soaking, take out the acid soaked oak bark;

[0063] (2) After the acid leached oak bark was dried naturally, it was repeatedly beaten with a wooden hammer for 40 minutes, rinsed with water for 3 times, put into an oven, heated to 100°C, and dried for 10 hours to obtain degummed oak bark fiber;

[0064] (3) Prepare an aqueous solution of N-methylmorpholine with a mass fraction of 30%, mix the aqueous solution of N-methylmorpholine with the above-mentioned degummed oak bark fiber at a mass ratio of 15:1, and put it into an ultrasonic oscillator, Ultrasonic oscillation reaction at a frequency of 35kHz for 1h, and pretreated oak bark fibers were obtained after the reaction;

[0065] Preparation of premodified oak bark fibers:

[0066] Mix the above-mentioned...

example 2

[0074] Preparation of pretreated oak bark fibers:

[0075] (1) Mix oak bark and citric acid solution with a mass fraction of 10% in a mass ratio of 1:10, put them into a beaker, heat up to 65°C, and soak for 1 hour. After soaking, take out the acid soaked oak bark;

[0076] (2) After the acid leached oak bark was dried naturally, it was repeatedly beaten with a wooden hammer for 45 minutes, rinsed with water for 4 times, put into an oven, heated to 105°C, and dried for 11 hours to obtain degummed oak bark fiber;

[0077] (3) Prepare an aqueous solution of N-methylmorpholine with a mass fraction of 30%, mix the aqueous solution of N-methylmorpholine with the above-mentioned degummed oak bark fiber at a mass ratio of 15:1, and put it into an ultrasonic oscillator, Ultrasonic oscillation reaction at a frequency of 38kHz for 2h, and pretreated oak bark fibers were obtained after the reaction;

[0078] Preparation of premodified oak bark fibers:

[0079] Mix the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com