High-strength steel and hard aluminum alloy combined body spraying phosphorization technology

A hard aluminum alloy and high-strength steel technology, which is applied in the field of spray phosphating process of high-strength steel and hard aluminum alloy combination, can solve the problem of affecting product tactical performance index and storage period, large difference in film quality on the surface of different metals, Difficulty in the same tank, synchronous spraying and phosphating film formation, etc., to achieve the effect of promoting the improvement of the surface technology level, easy film formation, and improving the quality of surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

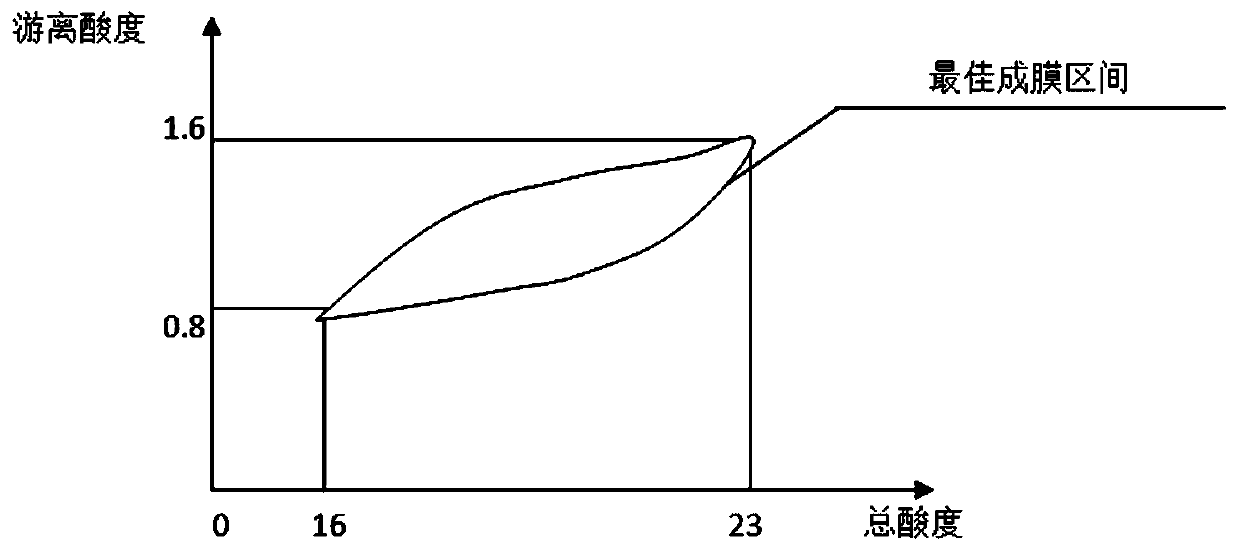

[0036] The alloy steel with a hardness of 42HRC-47HRC and a material of 30CrMnSiA and a hard aluminum alloy 2A12 sample are riveted together, and after degreasing and surface conditioning treatment, spray phosphating treatment in a bath composed of the following composition: Zn 2+ : 4000PPm, Mn 2+ : 500PPm, Fe 2+ : 400PPm, MoO 4 2- : 300PPm, NO 3 - : 9000PPm, PO 4 3- : 12000PPm, SO 4 2- : 400PPm. Composite accelerator (the ratio of fluorosilicate and cobalt salt is 2:1) 900PPm, composite accelerator (the ratio of nitrite and nitro compound is 3:1) 300PPm. Free acidity (Fa): 0.8 points, total acidity (Ta): 18 points, Ta / Fa=22.5; bath temperature: 40°C, pump gauge pressure: 0.04MPa, nozzle spray density 130L / m 2 Min, spray time 3min.

[0037] Under these conditions, the color of the obtained high-strength steel film layer is light gray to dark gray, and the phosphating film layer of hard aluminum alloy is light gray;

[0038] a. Phosphating film weight: 2.4g / m, coppe...

Embodiment 2

[0043] The alloy steel with a hardness of 41HRC-46HRC and a material of 30CrMnSiA and a hard aluminum alloy 2A12 sample are riveted together, and after degreasing and surface conditioning treatment, spray phosphating treatment in a bath composed of the following composition: Zn 2+ : 5000PPm, Mn 2+ : 700PPm, Fe 2+ : 500PPm, MoO 4 2- : 400PPm, NO 3 - : 12000PPm, PO 4 3- : 15000PPm, SO 4 2- : 550PPm. Composite accelerator (the ratio of fluorosilicate and cobalt salt is 2:1) 1200PPm, composite accelerator (the ratio of nitrite and nitro compound is 3:1) 450PPm. Free acidity (Fa): 1.2 points, total acidity (Ta): 22 points, Ta / Fa=18; bath temperature: 44°C, pump gauge pressure: 0.07MPa, nozzle spray density 170L / m 2 min, spray time 6min.

[0044] Under these conditions, the color of the obtained high-strength steel film layer is light gray to dark gray, and the phosphating film layer of hard aluminum alloy is light gray;

[0045] a. Phosphating film weight: 4g / m2, copper...

Embodiment 3

[0050] The alloy steel with a hardness of 42HRC-47HRC and a material of 30CrMnSiA and a hard aluminum alloy 2A12 sample are riveted together, and after degreasing and surface conditioning treatment, spray phosphating treatment in a bath composed of the following composition: Zn 2+ : 6000PPm, Mn 2+ : 800PPm, Fe 2+ : 600PPm, MoO 4 2- : 500PPm, NO 3 - : 15000PPm, PO 4 3- : 18000PPm, SO 4 2- : 700PPm. Composite accelerator (the ratio of fluorosilicate and cobalt salt is 2:1) 1500PPm, composite accelerator (the ratio of nitrite and nitro compound is 3:1) 600PPm. Free acidity (Fa): 1.6 points, total acidity (Ta): 26 points, Ta / Fa=16.3; bath temperature: 48°C, pump gauge pressure: 0.09MPa, nozzle spray density 190L / m 2 min, spray time 4min.

[0051] Under these conditions, the color of the obtained high-strength steel film layer is light gray to dark gray, and the phosphating film layer of hard aluminum alloy is light gray;

[0052] a. Phosphating film weight: 3.7g / m, cop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com