Single-arc shaver profiling template

A razor and profiling technology, which is applied in the direction of copying process control systems, metal processing equipment, manufacturing tools, etc., can solve problems such as shaving concaves and not meeting the requirements of drawings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

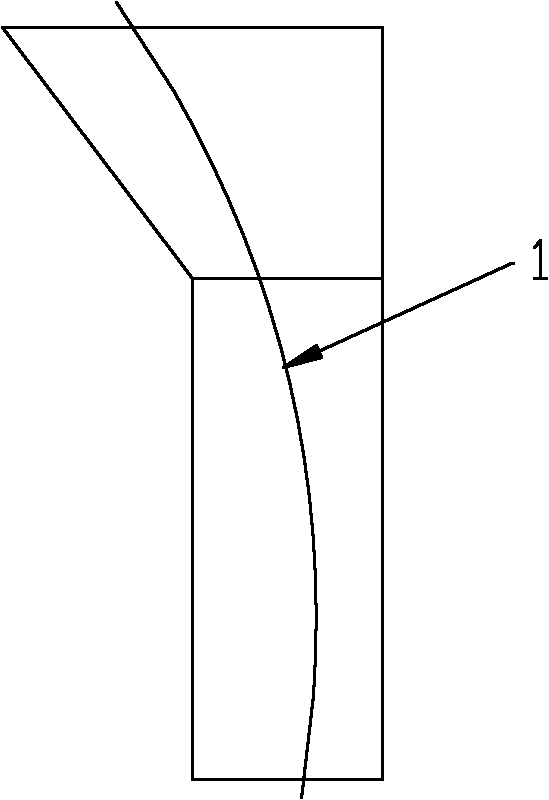

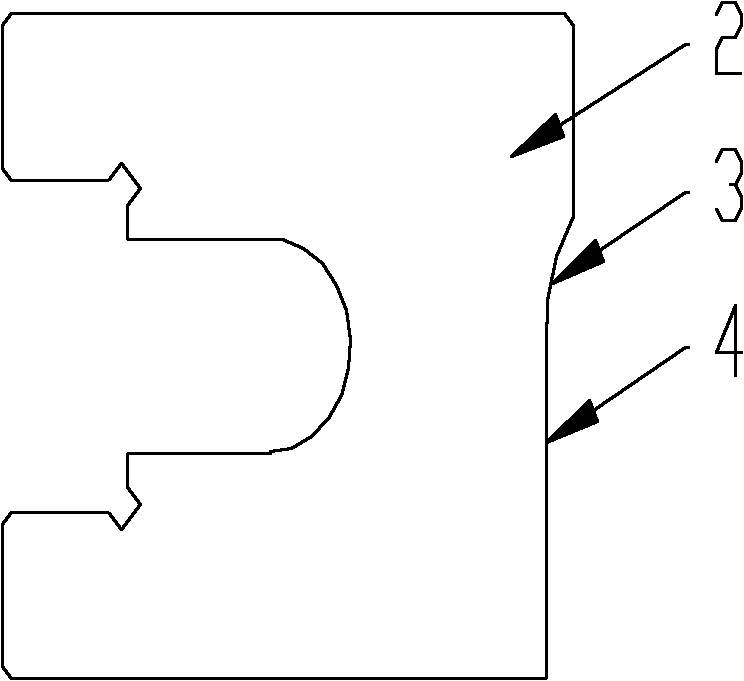

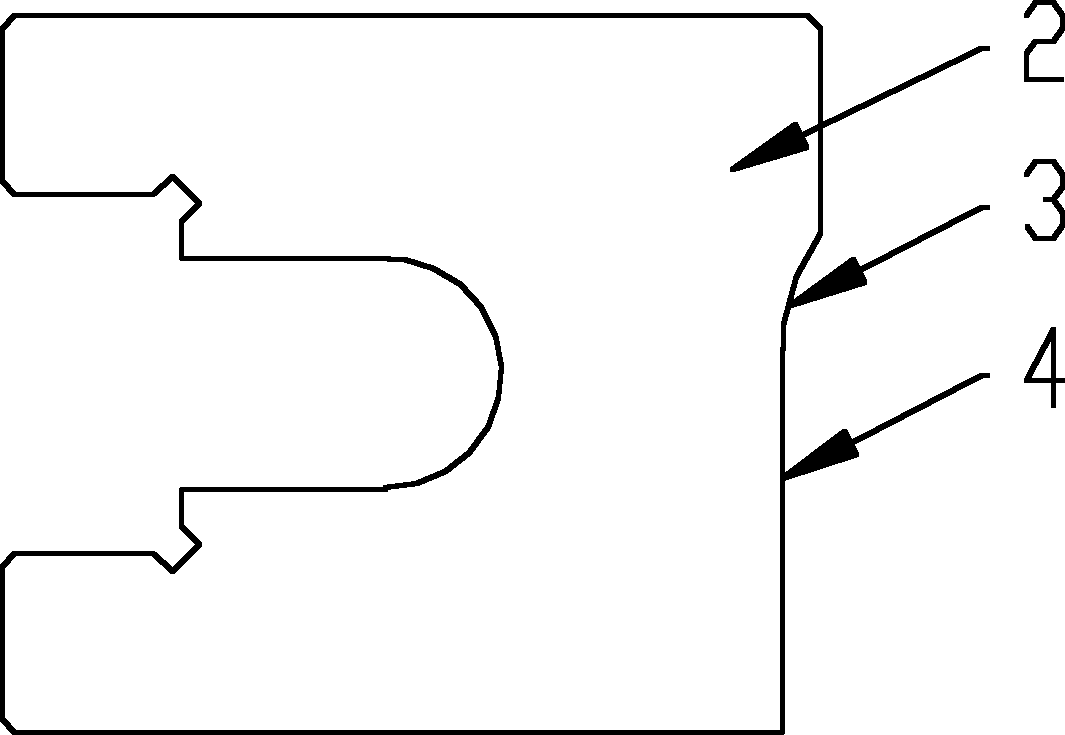

[0009] Such as figure 2 As shown, the curve of the single-arc razor template is designed so that one end is curved 3 and the other end is straight 4, and a single-arc razor template 2 that meets the design requirements is made by a special grinding method. Install the single-arc razor template 2 on the M7125 gear grinding machine for grinding wheel dressing, and then sharpen the shaving knife. The gear is shaved with a sharpened shaving knife, and the tooth shape inspection meets the requirements of the finished tooth shape line 1 of the product drawing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com