Preparation and application of nanorod array with adjustable resonance wavelength

A nanometer and array technology is applied in the field of preparation of silver nanorod arrays, which can solve the problems of low cost and short detection time, and achieve the effects of simple method, low cost and high sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

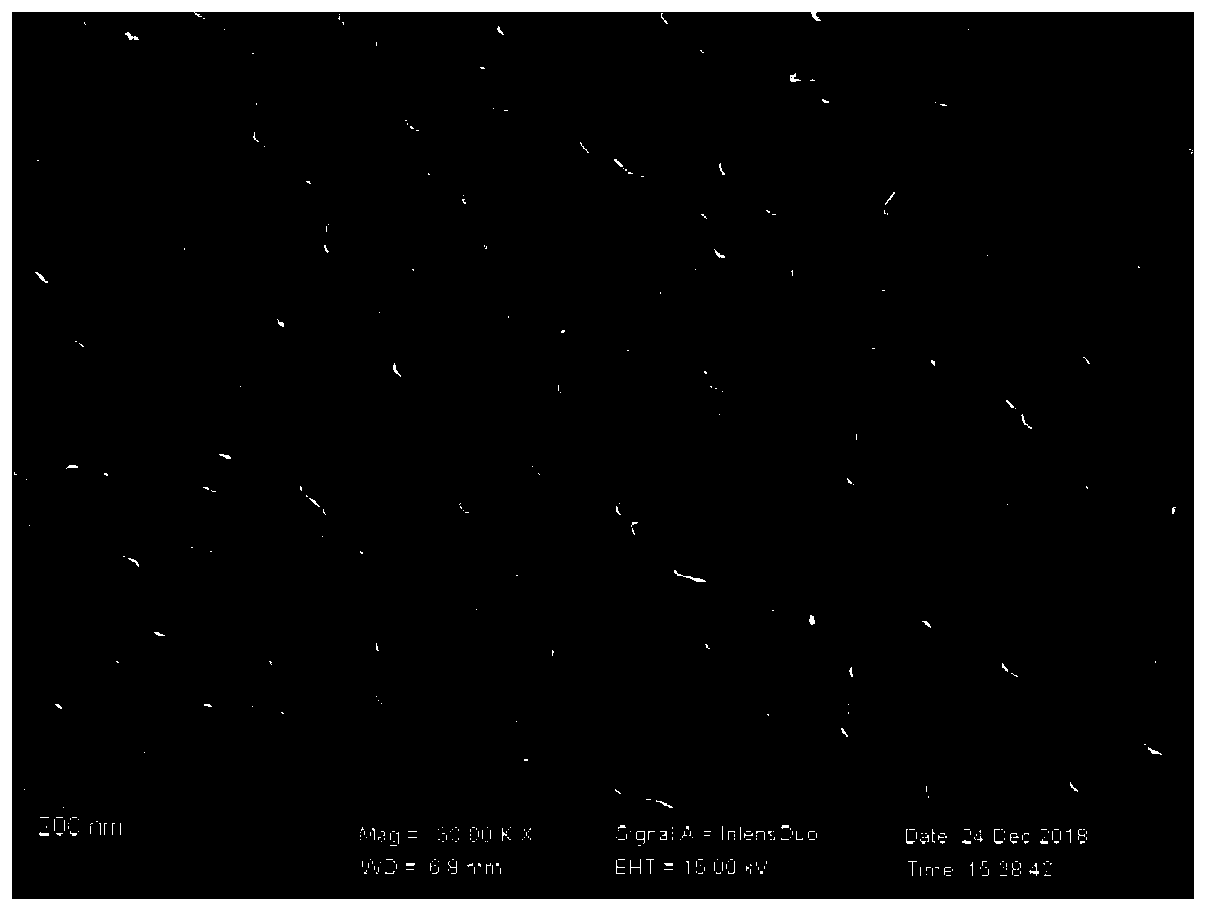

[0038] (1) After the silicon substrate or glass substrate is treated by the "piranha method", the substrate is covered with polystyrene (PS) microspheres of different diameters (50-1000nm);

[0039] (2) fixing the substrate prepared in (1) on the sample stage of the electron beam evaporation coating machine;

[0040] (3) Using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to 3×10 -5 ~2×10 -4 Pa high vacuum;

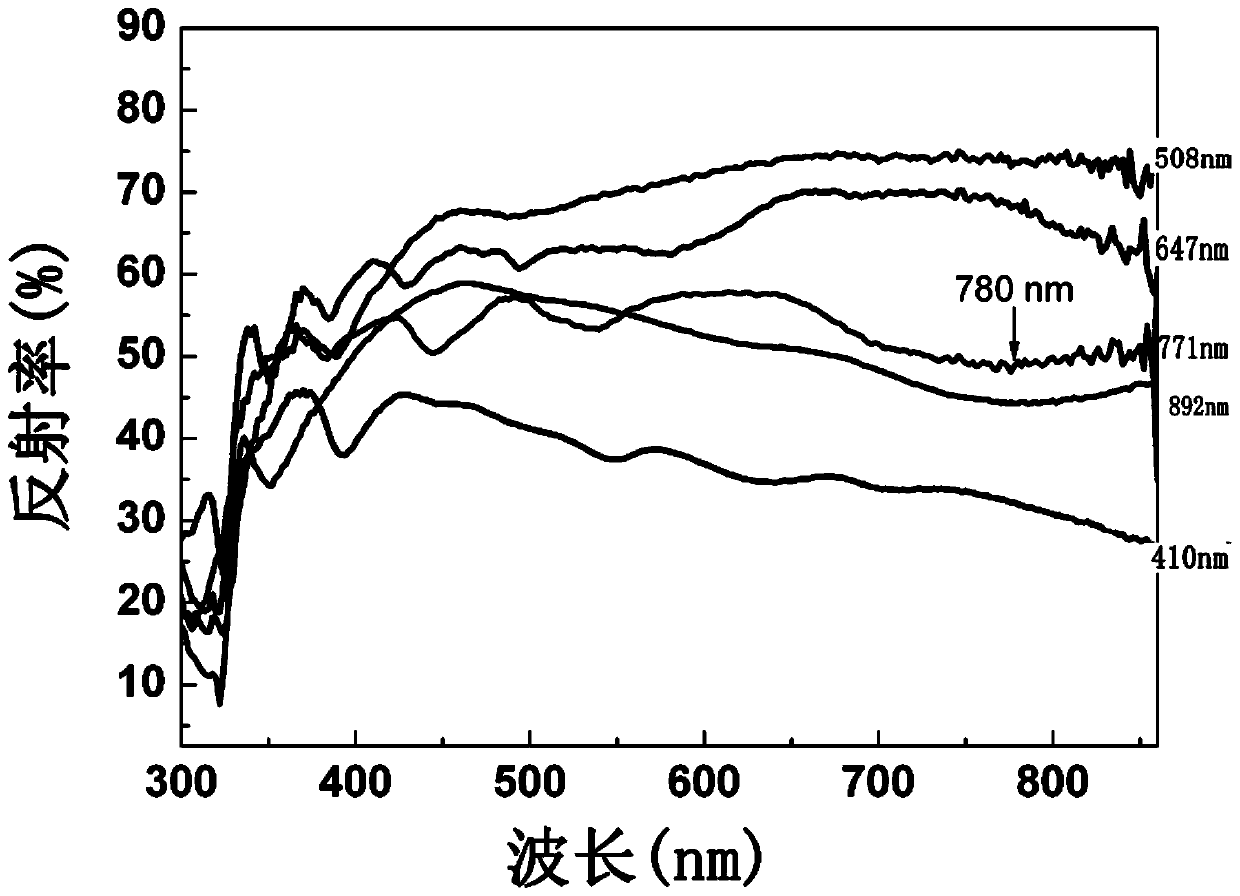

[0041] (4) Adjust the incident angle of the electron beam to 75-85 degrees, and make the sample stage static, grow a silver nanostructure film with a rod length of 647nm on the base of the sample stage, and the top of the nanorod has a plurality of bifurcated structures.

[0042] (5) The plasmon resonance excitation wavelength of the nanorod array can be adjusted by adjusting the length of the silver nanorods, so as to obtain the best enhancement under a specific Raman laser source.

Embodiment 2

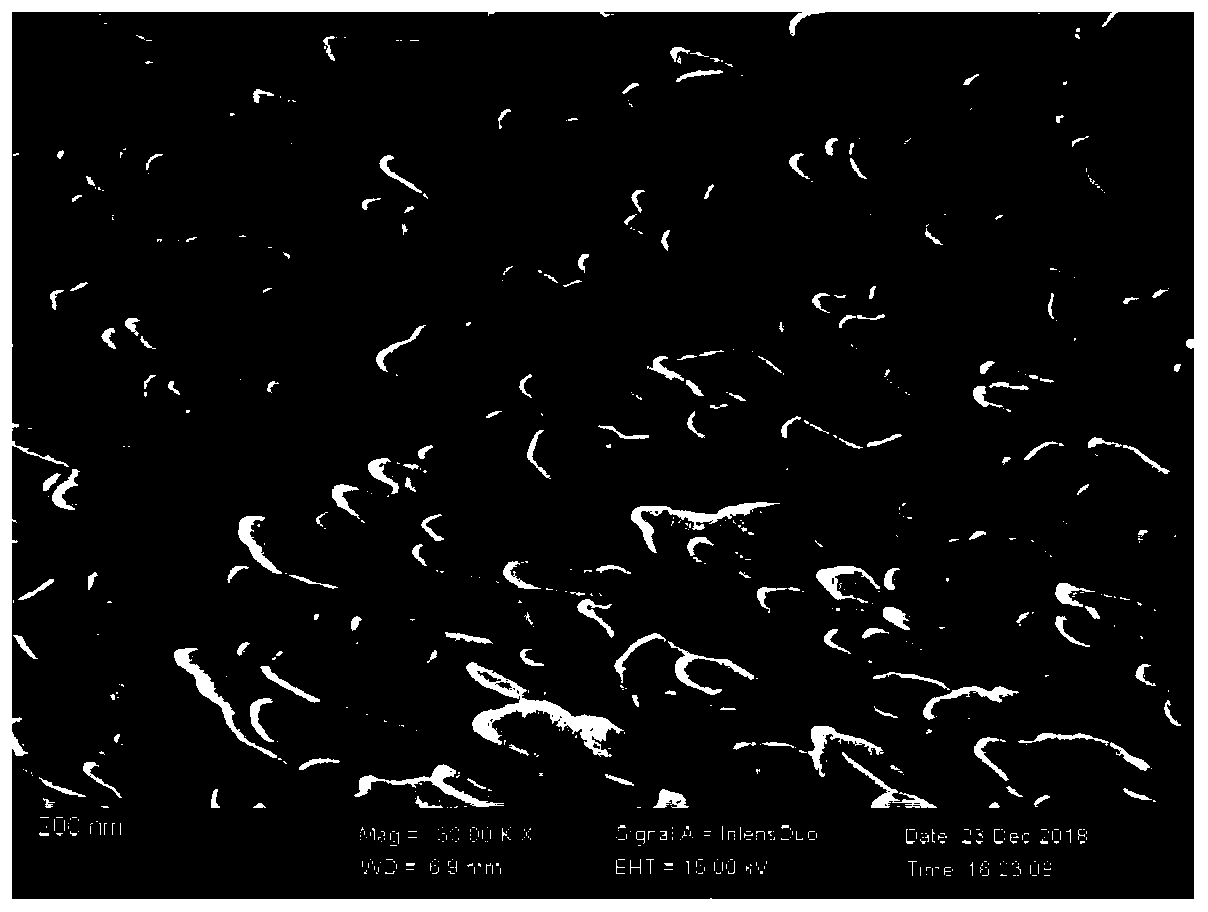

[0044] (1) After the silicon substrate or glass substrate is treated by the "piranha method", the substrate is covered with polystyrene (PS) microspheres with a diameter of 500 nm;

[0045] (2) fixing the substrate prepared in (1) on the sample stage of the electron beam evaporation coating machine;

[0046] (3) Using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to 3×10 -5 ~2×10 -4 Pa high vacuum;

[0047] (4) Adjust the incident angle of the electron beam to 75-85 degrees, and make the sample stage static, grow a silver nanostructure thin film with a rod length of 771 nm on the base of the sample stage, and the top of the nanorod has a plurality of bifurcated structures.

[0048] (5) The plasmon resonance excitation wavelength of the nanorod array can be adjusted by adjusting the length of the silver nanorods, so as to obtain the best enhancement under a specific Raman laser source.

[0049] (6) Mix 200 μL of trace...

Embodiment 3

[0053] (1) After the silicon substrate or glass substrate is treated by the "piranha method", the substrate is covered with polystyrene (PS) microspheres with a diameter of 500 nm;

[0054] (2) fixing the substrate prepared in (1) on the sample stage of the electron beam evaporation coating machine;

[0055] (3) Using metallic silver as the target material, pump the chamber of the electron beam evaporation coating machine to 3×10 -5 ~2×10 -4 Pa high vacuum;

[0056] (4) Adjust the incident angle of the electron beam to 75-85 degrees, and make the sample stage static, grow a silver nanostructure film with a rod length of 892nm on the base of the sample stage, and the top of the nanorod has a plurality of bifurcated structures.

[0057] (5) The plasmon resonance excitation wavelength of the nanorod array can be adjusted by adjusting the length of the silver nanorods, so as to obtain the best enhancement under a specific Raman laser source.

[0058] (6) Mix 200 μL of trace hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com