Thermo-oxidative aging-resistant low-precipitation MCA flame-retardant PA66 composite material and application thereof

A technology of PA66 and composite materials, which is applied in the field of heat-resistant oxygen aging and low-precipitation MCA flame-retardant PA66 composite materials. Effect of Flame Retardant Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

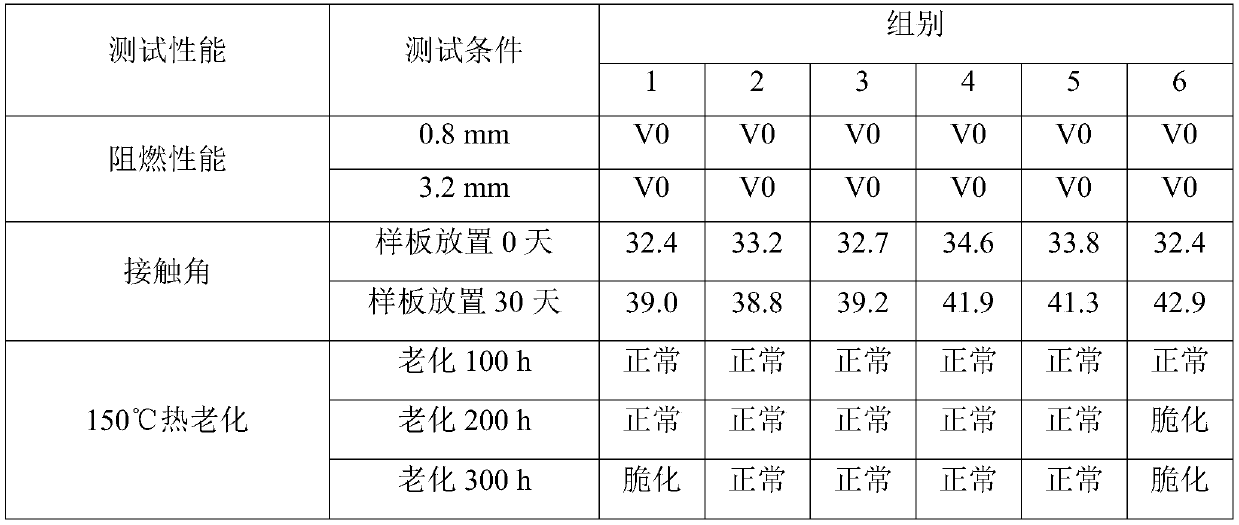

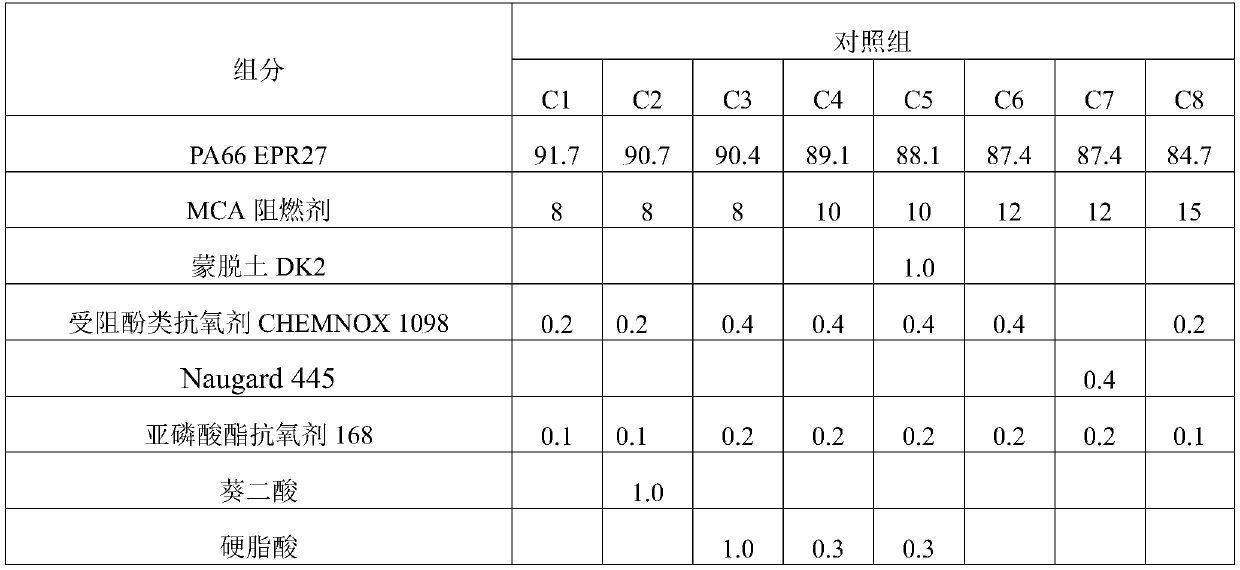

Examples

Embodiment 1

[0041] Example 1 Preparation of heat-resistant oxygen aging low-precipitation MCA flame-retardant PA66 composite material

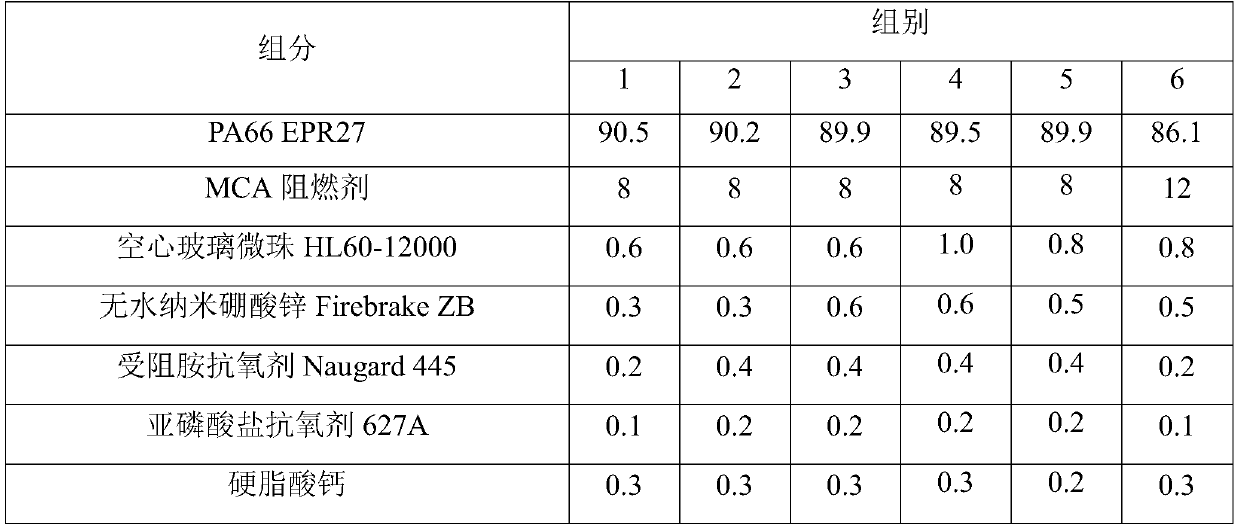

[0042] Weigh the raw materials of Groups 1 to 6 according to Table 1 below, and extrude and granulate them through a twin-screw extruder. Among them, the premixed PA66 resin, MCA flame retardant, antioxidant, flame retardant stabilizer and boric acid The zinc mixture is added from the main feeding port of the twin-screw extruder, and the hollow glass microspheres are added from the side feeding port of the extruder. Adjust the processing technology so that the hollow glass microspheres are evenly dispersed and less broken during processing; the mixture is melted, blended and extruded by a twin-screw extruder, then cooled, air-dried, and pelletized to obtain heat-resistant, oxygen-aging and low-precipitation MCA flame-retardant PA66 composite material.

[0043] Table 1: Raw material components and dosage (unit: kg) used to prepare the MCA flame-retardant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com