Ternary positive electrode material with high volume energy density for lithium ion battery and preparation method

A technology for lithium ion batteries and cathode materials, which is applied in the field of synthesis of high volume energy density single crystal ternary cathode materials for lithium ion batteries, can solve problems such as the influence of capacity and stability, uneven distribution of doping elements, etc. Wide range, the effect of increasing volume energy density, increasing compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

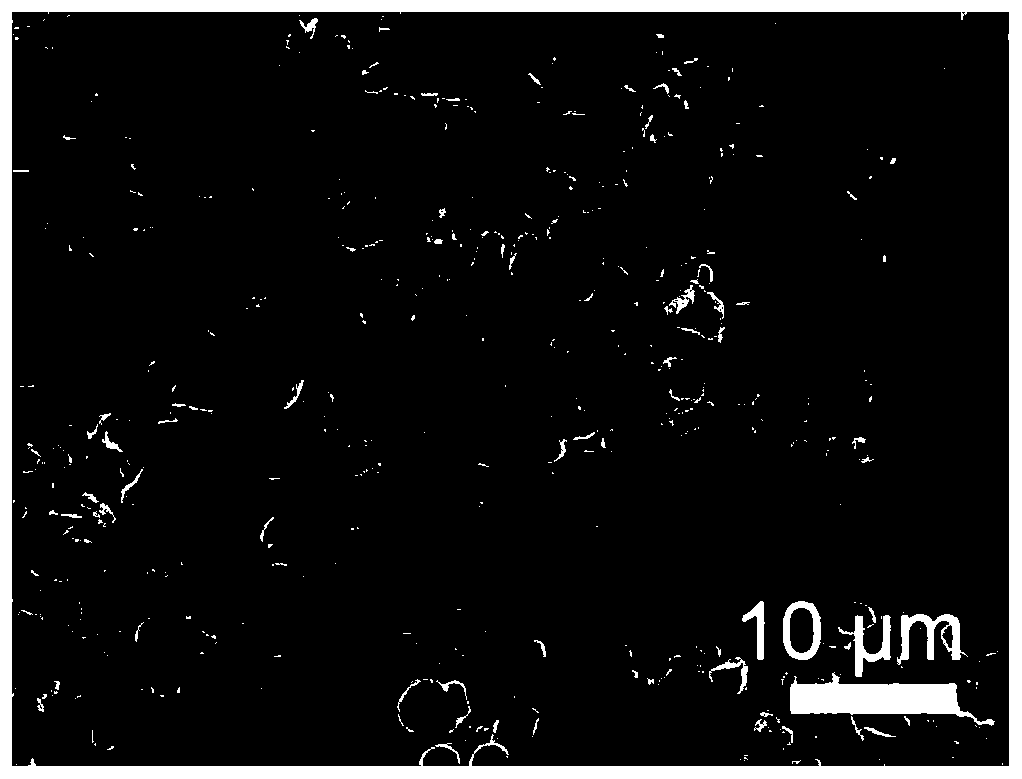

Image

Examples

Embodiment 1

[0043] S1, first set Ni 0.8 co 0.1 mn 0.1 (OH) 2 Precursor, lithium hydroxide monohydrate, aluminum oxide, titanium oxide and boron oxide are mixed with ethanol: water as a mixed solvent of 1:3, and then fully ground with a ball mill and spray-dried to obtain a solid powder to form a uniform mixture. , The molar ratio of lithium hydroxide monohydrate, aluminum oxide, titanium oxide and boron oxide is 1:1.05:0.005:0.01:0.015;

[0044] S2, pre-sintering at 700°C for 5 hours in an atmosphere furnace with an oxygen volume fraction of 99%, and adding titanium isopropoxide as a shape modifier after cooling, wherein the molar ratio of NCM precursor to titanium isopropoxide is 1: 0.005, use a ball mill to mix evenly;

[0045] S3, sintering in an atmosphere furnace with an oxygen volume fraction of 99%, the specific sintering procedure is 5°C·min -1 The heating rate is increased to 500°C and kept for 8 hours; then at 5°C·min -1 The heating rate was raised to 650°C, and kept for 8...

Embodiment 2

[0047] Others are the same as in Example 1, the difference is that the raw material is Ni in S1 0.8 co 0.1 mn 0.1 (OH) 2 The precursor, lithium hydroxide monohydrate, aluminum hydroxide, and titanium oxide are mixed according to the molar ratio of 1:1.05:0.015:0.015, and finally a ternary lithium battery positive electrode material with a primary particle size D50 of about 8.8 μm is obtained.

Embodiment 3

[0049] Others are the same as in Example 1, the difference is that the raw material is Ni in S1 0.8 co 0.1 mn 0.1 (OH) 2 The precursor, lithium hydroxide monohydrate, alumina, and zirconium ethoxide are mixed according to the molar ratio of 1:1.05:0.01:0.02, and finally a ternary lithium battery cathode material with a primary particle size D50 of about 8.2 μm is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com