Method for preparing single-layer large-area graphene by utilizing metal intercalation

A single-layer graphene, large-area technology, applied in the direction of single-layer graphene, graphene, nano-carbon, etc., can solve the problems of difficult to control layer thickness and many defects, achieve low temperature dependence, simple preparation conditions, repeatable good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) A grade A single crystal 6H-SiC (0001) substrate with a size of 15mm×3mm×330μm was selected as the growth substrate of epitaxial graphene;

[0045] 2) Place the single crystal SiC substrate in a vacuum preparation chamber and heat it to 820K for degassing. The pressure of the vacuum preparation chamber is maintained at 5×10 -10 Torr, the DC power used is 0.5A, and the water vapor and residue adsorbed on the surface of the single crystal SiC are removed after 8 hours of degassing;

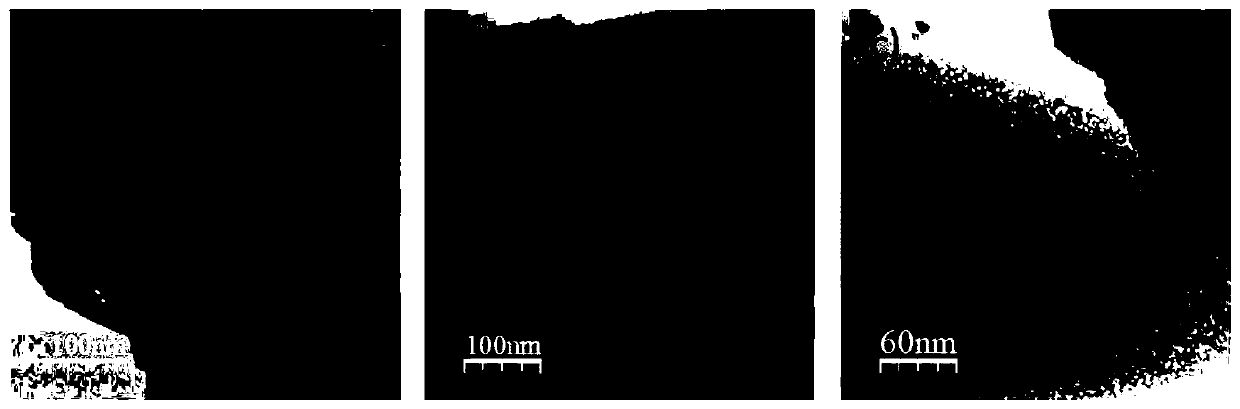

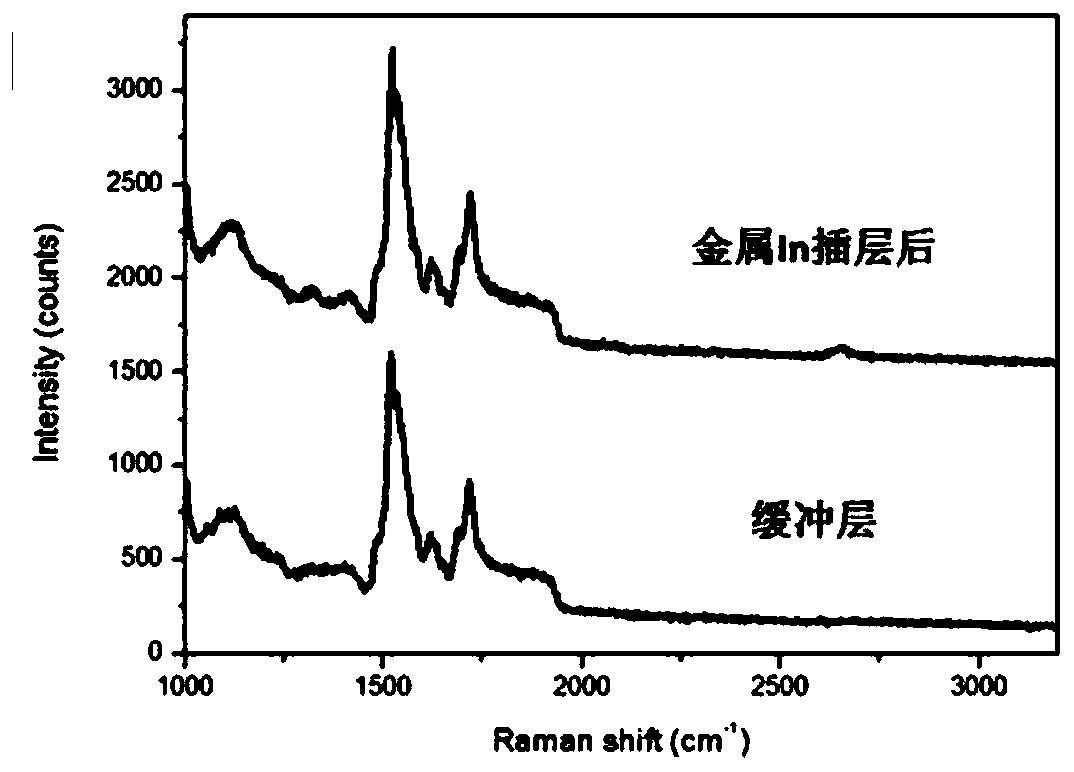

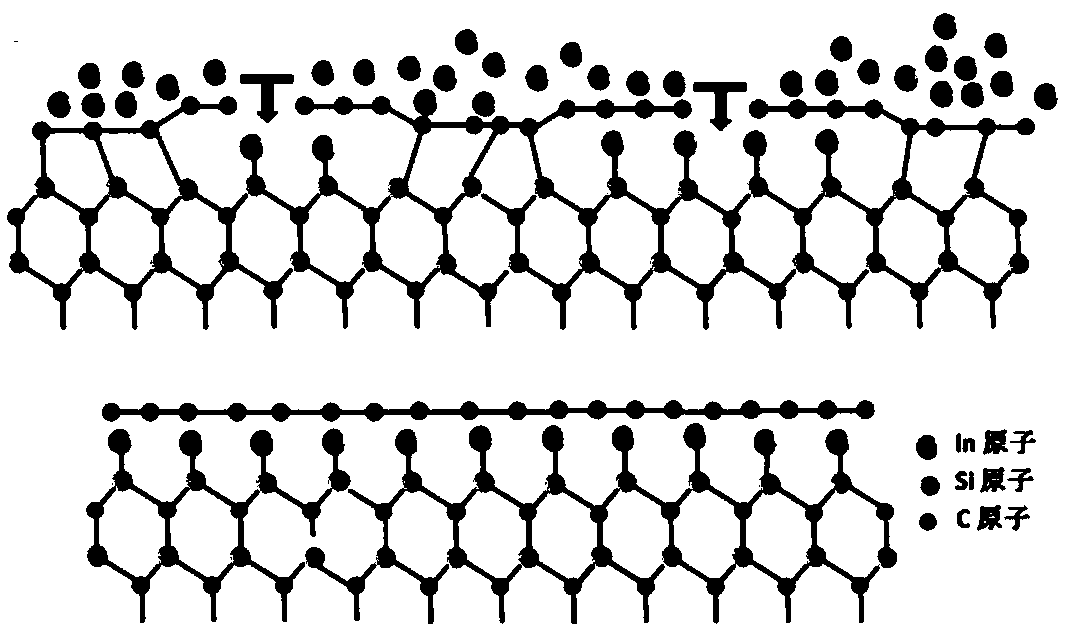

[0046] 3) Raise the temperature of the single crystal SiC substrate obtained in step 2) to 1470K and keep it for 15 minutes, so that a large-area buffer layer is formed on the surface of SiC, and the morphology of the single crystal SiC surface covered by the buffer layer is as follows: figure 1 as shown in (a);

[0047] 4) heating the metal In source in the crucible K~Cell device;

[0048] 5) Maintain the temperature of the single crystal SiC substrate at 80K, open the baffle of the met...

Embodiment 2

[0053] 1) A grade A single crystal 6H-SiC (0001) substrate with a size of 15mm×3mm×330μm was selected as the growth substrate of epitaxial graphene;

[0054] 2) Place the single crystal SiC substrate in a vacuum preparation chamber and heat to 800K to degas, and the pressure of the vacuum preparation chamber is maintained at 5×10 -10 Torr, the DC power used is 0.48A, and after 8 hours of degassing, the water vapor and residue adsorbed on the surface of the single crystal SiC are removed;

[0055] 3) Raise the temperature of the single crystal SiC substrate obtained in step 2) to 1620K and keep it for 5 minutes, so that the SiC surface forms a buffer layer and the single-layer epitaxial graphene coexists on the surface, and the surface of the single crystal SiC covered by the buffer layer and epitaxial graphene looks like Figure 4 as shown in (a);

[0056] 4) heating the metal In source in the crucible K~Cell device;

[0057] 5) Maintain the temperature of the single crysta...

Embodiment 3

[0062] 1) A grade A single crystal 6H-SiC (0001) substrate with a size of 15mm×3mm×330μm was selected as the growth substrate of epitaxial graphene;

[0063] 2) Place the single crystal SiC substrate in a vacuum preparation chamber and heat it to 840K for outgassing. The pressure of the vacuum preparation chamber is maintained at 5×10 -10 Torr, the DC power used is 0.52A, and the water vapor and residue adsorbed on the surface of the single crystal SiC are removed after 8 hours of degassing;

[0064] 3) heating the single crystal SiC substrate obtained in step 2) to 1470K and keeping it for 12 minutes, so that a large-area buffer layer is formed on the SiC surface;

[0065] 4) heating the metal In source in the crucible K~Cell device;

[0066] 5) Maintain the temperature of the single crystal SiC substrate at 80K, open the baffle of the metal beam source, and deposit metal In atoms. During the deposition process, the heating current of the metal In source is 2.8A, the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com