Conditioning agent for heavy metal contaminated soil and preparation method thereof

A technology for polluted soil and heavy metals, applied in the field of conditioners and preparations of heavy metal polluted soils, can solve problems such as unsuitability for large-scale polluted soil treatment, threats to residents and ecological environment, toxic organic matter pollution, etc., and achieves improvement of soil physical and chemical properties, The effect of improving water retention and ventilation performance and pH value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

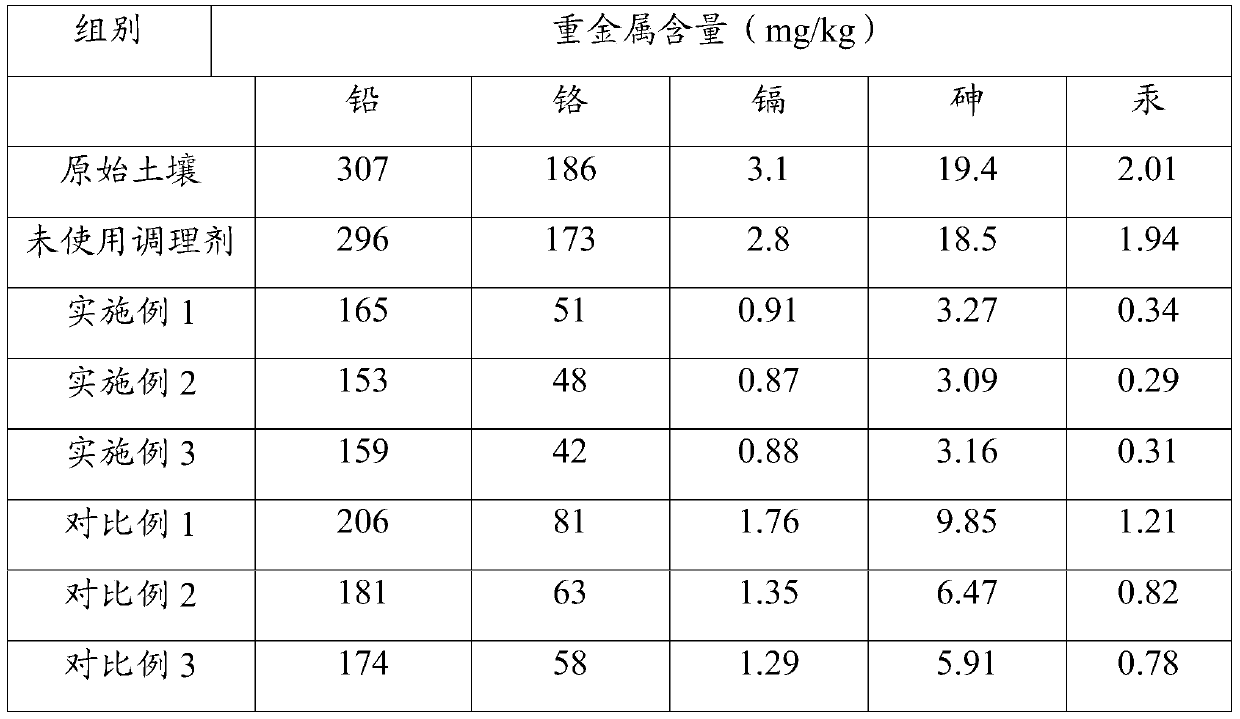

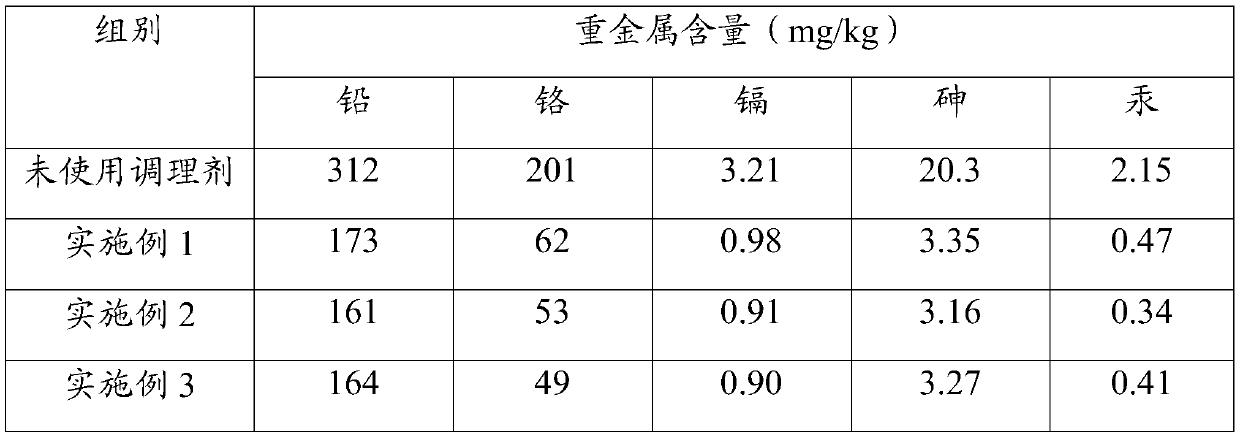

Examples

Embodiment 1

[0032] The present embodiment provides a conditioner for heavy metal-contaminated soil, which consists of the following raw materials by mass:

[0033] 55 parts of modified activated carbon, 20 parts of humic acid, 8 parts of compound microbial inoculum, 12 parts of sodium sulfide, 15 parts of potassium dihydrogen phosphate, 14 parts of diatomaceous earth, 9 parts of calcium oxide, 15 parts of modified zeolite, organic fertilizer 18 servings;

[0034] The composite microbial inoculum consists of the following raw materials by mass: 2.5 parts of Bacillus, 2 parts of Acetobacter, and 2.5 parts of EM bacteria.

[0035] The present embodiment also provides a preparation method of the above conditioning agent, comprising the following steps:

[0036] Step 1: Mix the crop straw and potassium hydroxide in a mass ratio of 1:0.2, pyrolyze at 700 °C for 2 hours under the protection of argon, and cool to obtain activated carbon; the activated carbon is mixed with 4mol / L sulfuric acid in...

Embodiment 2

[0043] The present embodiment provides a conditioner for heavy metal-contaminated soil, which consists of the following raw materials by mass:

[0044] 50 parts of modified activated carbon, 15 parts of humic acid, 4 parts of compound microbial inoculum, 9 parts of sodium sulfide, 12 parts of potassium dihydrogen phosphate, 8 parts of diatomaceous earth, 6 parts of calcium oxide, 10 parts of modified zeolite, organic fertilizer 15 servings;

[0045] The composite microbial inoculum consists of the following raw materials by mass: 1 part of Bacillus, 1 part of Acetobacter, and 3 parts of EM bacteria.

[0046] The present embodiment also provides a preparation method of the above conditioning agent, comprising the following steps:

[0047] Step 1. Mix peanut shells and potassium hydroxide in a mass ratio of 1:0.3, and pyrolyze them at 600 °C for 3 hours under the protection of argon, and cool to obtain activated carbon; the activated carbon is mixed with 4 mol / L nitric acid in ...

Embodiment 3

[0054] The present embodiment provides a conditioner for heavy metal-contaminated soil, which consists of the following raw materials by mass:

[0055] 60 parts of modified activated carbon, 24 parts of humic acid, 12 parts of compound microbial inoculum, 15 parts of sodium sulfide, 19 parts of potassium dihydrogen phosphate, 20 parts of diatomaceous earth, 12 parts of calcium oxide, 20 parts of modified zeolite, organic fertilizer 20 servings;

[0056] The composite microbial inoculum consists of the following raw materials by mass: 4 parts of Bacillus, 3 parts of Acetobacter, and 2 parts of EM bacteria.

[0057] The present embodiment also provides a preparation method of the above conditioning agent, comprising the following steps:

[0058] Step 1. Mix the crop straw and potassium hydroxide in a mass ratio of 1:0.5, pyrolyze at 800 °C for 1 h under argon protection, and cool to obtain activated carbon; the activated carbon is mixed with 2 mol / L chlorine in a ratio of 100 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com