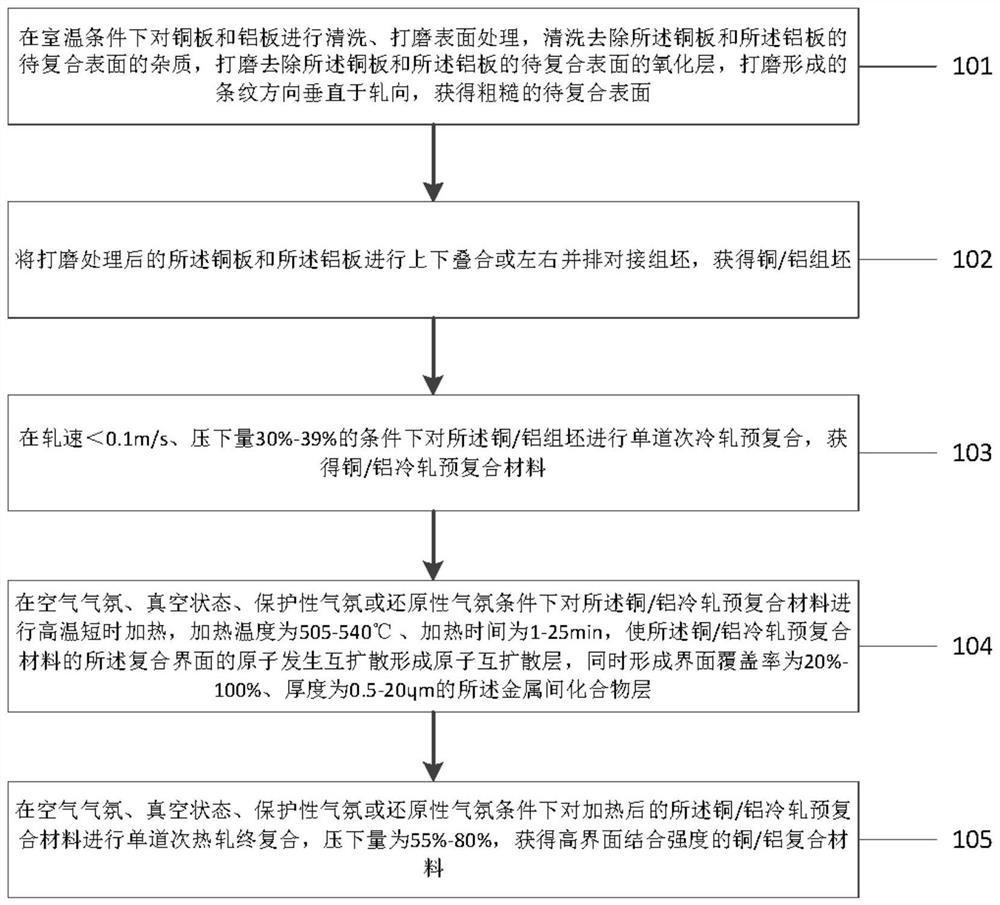

A forming method of copper/aluminum composite material with high interfacial bonding strength

A technology of interface bonding strength and aluminum composite materials, which is applied in metal rolling, metal processing equipment, auxiliary arrangements, etc., can solve problems such as low bonding strength and high interface bonding strength, achieve large interface friction and improve interface bonding strength , The effect of reducing the requirement of rolling mill capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of T2 pure copper / 1060 pure aluminum composites with high interfacial bonding strength.

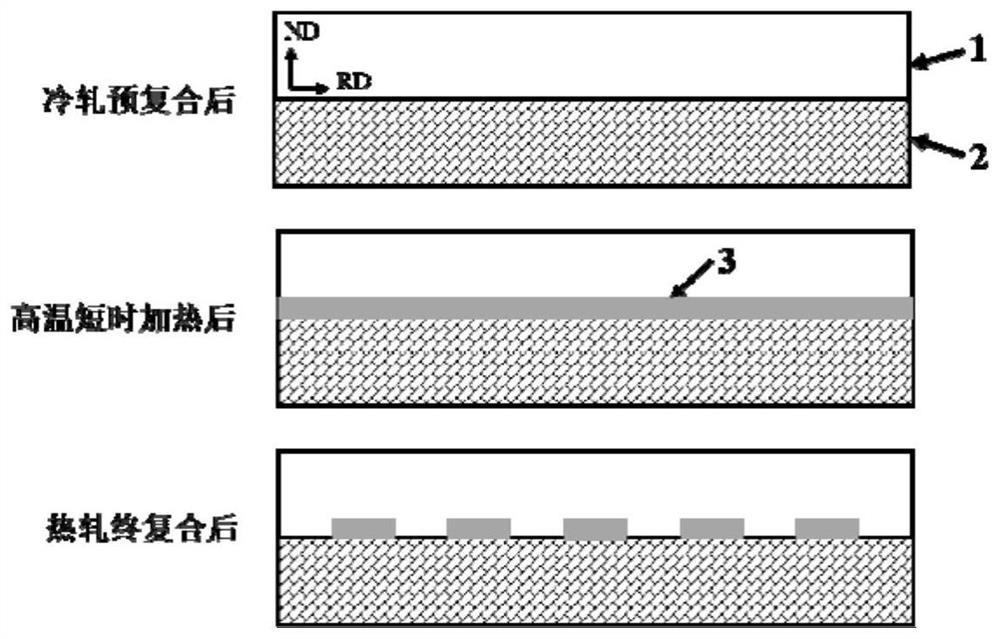

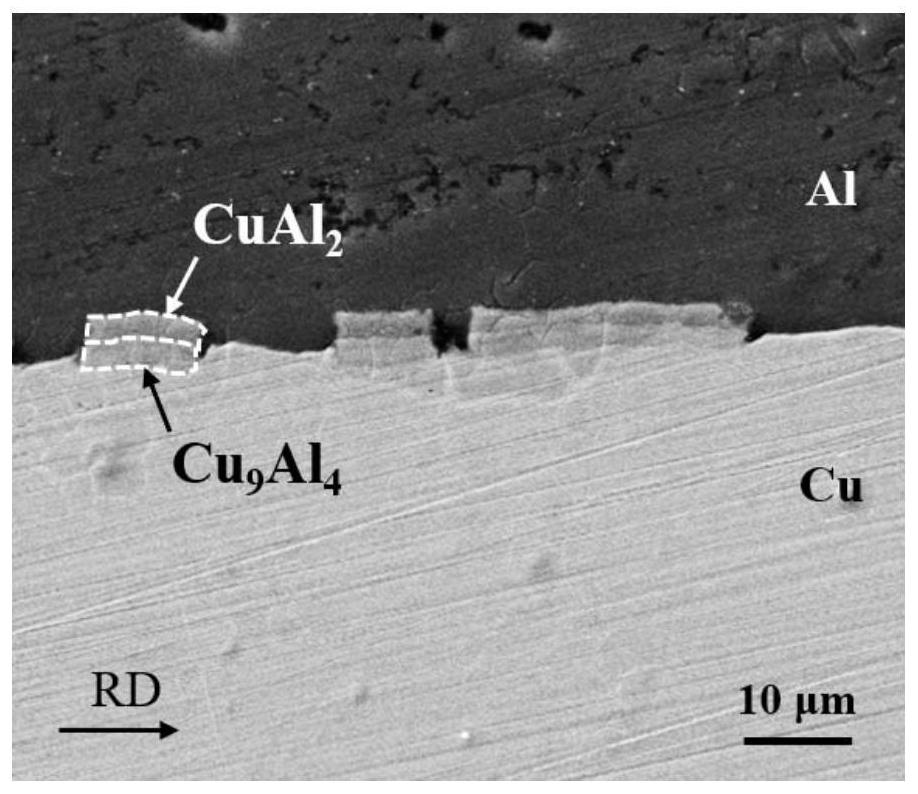

[0041] At room temperature, the annealed soft state T2 pure copper plate (thickness 5mm) and the annealed soft state 1060 pure aluminum plate (thickness 3mm) were cleaned with alcohol and surface treated by louver grinding. Composite surface; the surface-treated pure copper plate and pure aluminum plate are stacked up and down to obtain a copper / aluminum billet; then a single-pass pre-cold rolling is carried out under the conditions of a rolling speed of 0.08m / s and a reduction of 35%. Composite to obtain the copper / aluminum cold-rolled pre-composite material; then, in the air atmosphere and under the conditions of heating temperature 505 ° C and heating time 15 minutes, the copper / aluminum cold-rolled pre-composite material is heated at a high temperature and short time to make the copper / aluminum cold-rolled pre-composite material The composite interface atoms of the ...

Embodiment 2

[0043] Preparation of T1 pure copper / 1060 pure aluminum composites with high interfacial bonding strength.

[0044] At room temperature, the annealed soft state T1 pure copper plate (thickness 2mm) and the annealed soft state 1060 pure aluminum plate (thickness 3mm) were cleaned with alcohol and surface treated by louver grinding. Composite surface; and the surface treated pure copper plate and pure aluminum plate are docked side by side to obtain a copper / aluminum billet; then a single pass pre-cold rolling is carried out under the conditions of a rolling speed of 0.05m / s and a reduction of 39%. Composite to obtain the copper / aluminum cold-rolled pre-composite material; then, in the air atmosphere and under the conditions of heating temperature 540 ° C and heating time 2 minutes, the copper / aluminum cold-rolled pre-composite material is heated at a high temperature for a short time to make the copper / aluminum cold-rolled pre-composite material The composite interface atoms of...

Embodiment 3

[0046] Preparation of T1 pure copper / 3003 aluminum alloy composites with high interfacial bonding strength.

[0047] At room temperature, the annealed soft state T1 pure copper plate (thickness 2mm) and the annealed soft state 3003 aluminum alloy plate (thickness 6mm) were cleaned by alcohol and polished by grinding wheel. Composite surface; and the surface-treated pure copper plate and aluminum alloy plate are butted side by side to obtain a copper / aluminum billet; then single-pass cold rolling is carried out under the conditions of a rolling speed of 0.04m / s and a reduction of 37%. Pre-composite to obtain the copper / aluminum cold-rolled pre-composite material; then, in the air atmosphere and under the conditions of a heating temperature of 520 ° C and a heating time of 10 minutes, the copper / aluminum cold-rolled pre-composite material is heated at a high temperature for a short time to make the copper / aluminum cold-rolled The composite interface atoms of the pre-composite ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com