Random vibration drive ring-down cavity calibration-free gas concentration measurement system and method

A technology of gas concentration measurement and random vibration, which is applied in the direction of measuring device, color/spectral characteristic measurement, and material analysis through optical means, which can solve problems such as fluctuations, simplify experimental operations and measuring devices, simplify system structure, and suppress effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

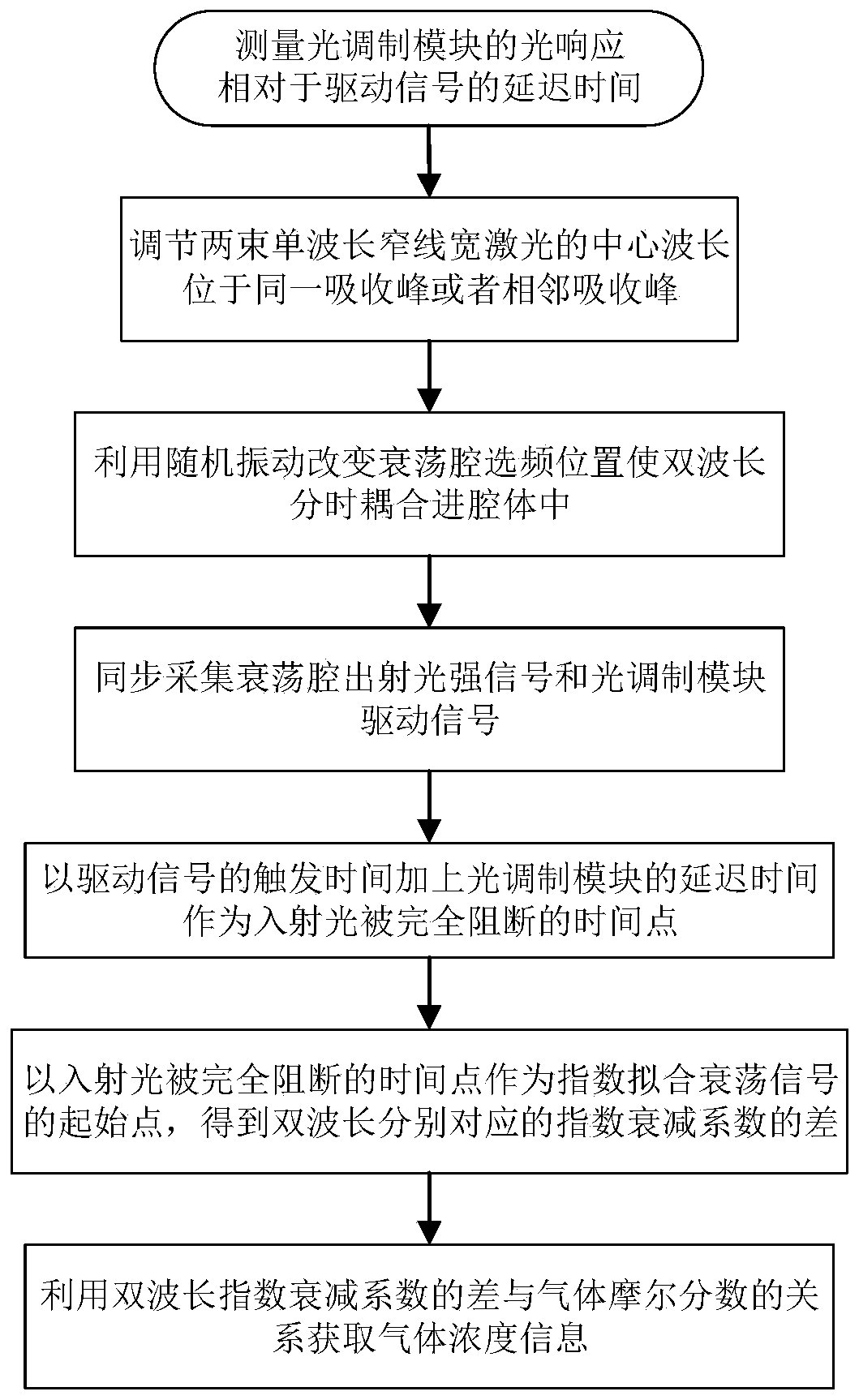

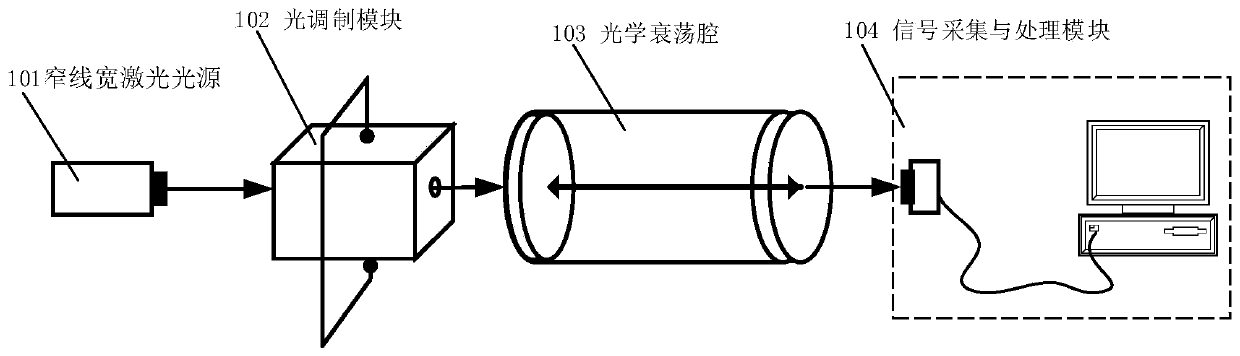

[0023] This paper invents a vibration-resistant and calibration-free gas concentration measurement system and method based on a ring-down cavity. The structure of the system is as follows: figure 2 Among them, the narrow-linewidth laser light source (101) emits two beams of narrow-linewidth laser beams with different wavelengths, which pass into the light modulation module (102) and are periodically turned off, and then incident on a set of high-reflectivity reflectors driven by random vibrations. In the optical ring-down cavity (103) composed of mirrors, the light intensity exponential attenuation signal at the exit end is introduced into the signal acquisition and processing module (104), and finally realizes the random vibration-driven ring-down cavity free of calibration gas concentration measurement.

[0024] Based on the above-mentioned device, the specific implementation of the system is described as follows:

[0025] Step 1: Measure the delay time t of the optical res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com