Silk-like fabric and preparation method thereof

A technology for imitating silk and fabrics, applied in the textile field, can solve the problems of poor moisture absorption and moisture conductivity, poor clothing feel, insufficient softness, etc., and achieve the effects of bright gloss, low cost of raw materials, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

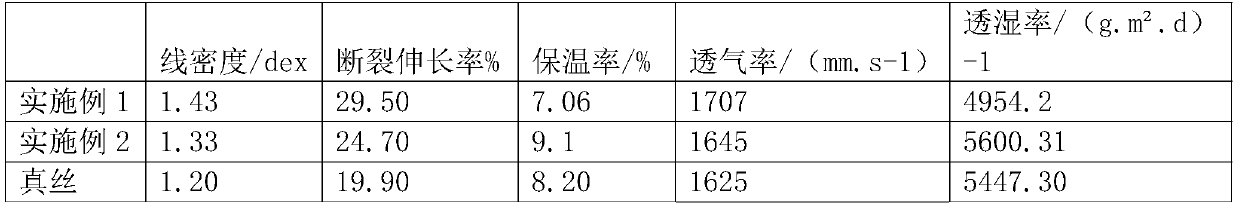

Examples

Embodiment 1

[0026] Step 1. Yarn preparation

[0027] Weft thread: Use a super pulverizer to pulverize cotton linters, the pulverized particle size is less than 2.5mm, dissolve to a mass fraction of 90% NMMO solution, the dissolution temperature is 120°C, and the dissolution reaction is 1 hour. Dehydration by padding, filtration, nano-grinding, incorporation into PET, and melting to make porous triangular polyester with a fineness below 1.0D.

[0028] Warp: Porous fine-denier different-faced polyester made by PET melt-spinning method, with a fineness of less than 1.0D.

[0029] Step 2, warping: Warp the warp yarns in batches, wind them into pulp shafts, and warp at a speed of 500 m / min;

[0030] Step 3, sizing: the warped yarn is soaked in the size tank through the size tank, the mass fraction of the dissolved modified starch in the slurry is 20%, the mass fraction of the polyacrylate size is 25%, the temperature is 95°C, and the sizing rate is 6 -8%; and then dried in a drying room, the...

Embodiment 2

[0036] Step 1. Yarn preparation

[0037] Weft: Use a super pulverizer to pulverize cotton linters with a mass fraction of 90% and sisal hemp with a mass fraction of 10%. The particle size of the pulverized particles is less than 2.5mm, and then dissolved to a NMMO solution with a mass fraction of 90%. The dissolution temperature is 120°C and the dissolution reaction is carried out for 1 hour. Dehydration by padding, filtration, nano-grinding, incorporation into PET, and melting to make porous triangular polyester with a fineness below 1.0D.

[0038] Warp: Porous fine-denier different-faced polyester made by PET melt-spinning method, with a fineness of less than 1.0D.

[0039] Step 2, warping: Warp the warp yarns in batches, wind them into pulp shafts, and warp at a speed of 250-580 m / min;

[0040] Step 3, sizing: the warped yarn is soaked in the size tank through the size tank, the mass fraction of the dissolved modified starch in the slurry is 20%, the mass fraction of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com