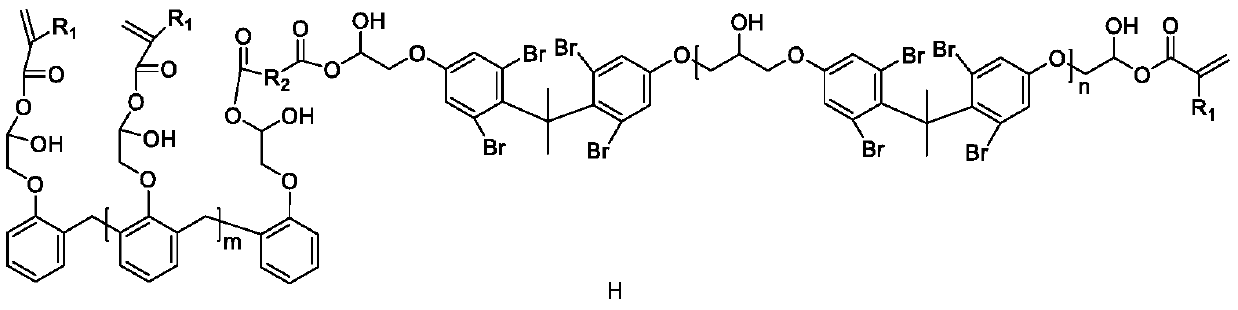

Vinyl ester resin as well as preparation method and application thereof

A vinyl ester resin, resin technology, applied in the field of vinyl ester resin and its preparation, can solve the problems of corrosion resistance, mechanical properties, easy to decompose, affect deep curing, etc., to achieve uniform distribution and avoid yellowing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

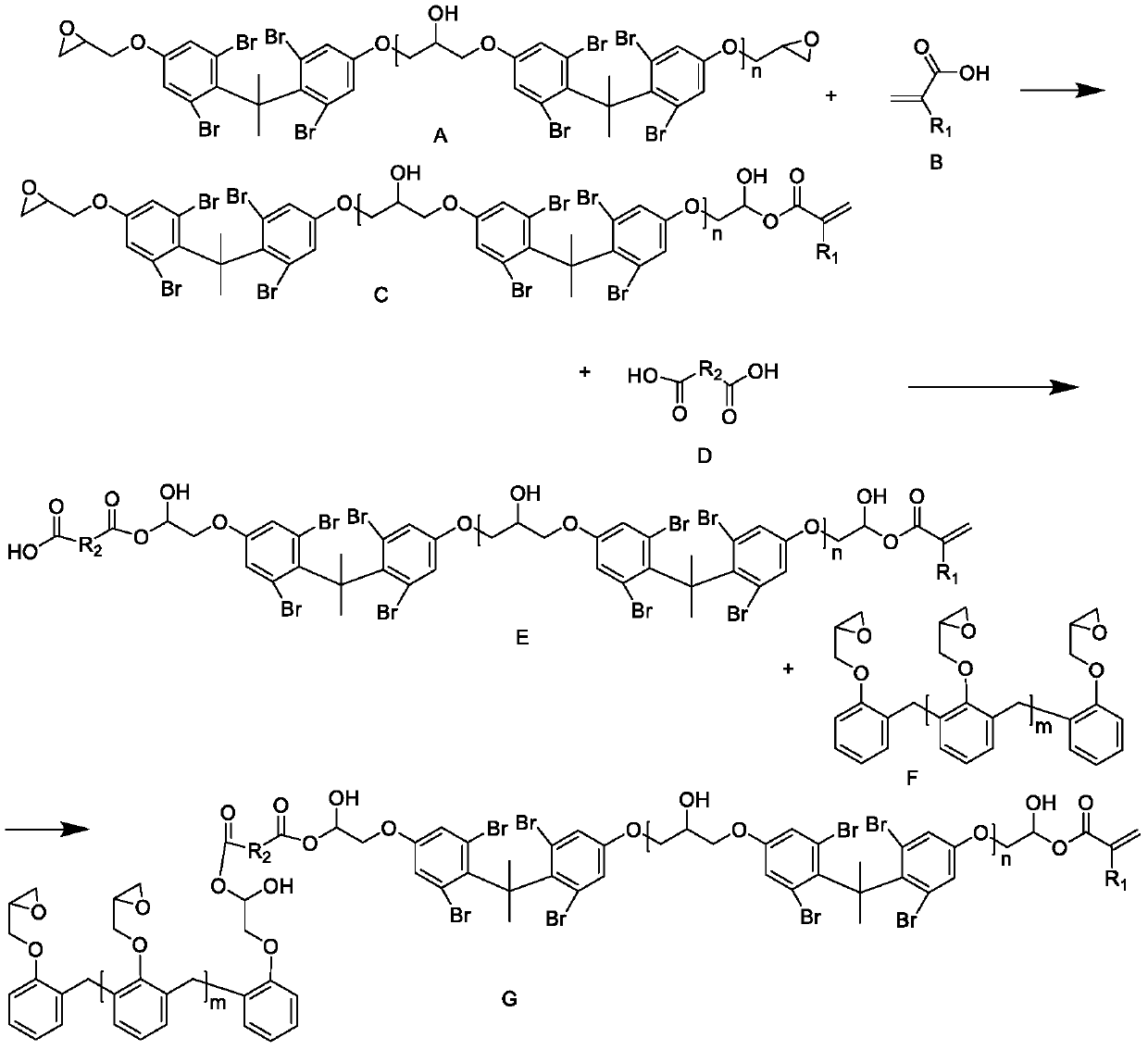

Method used

Image

Examples

Embodiment 1

[0092] The present embodiment provides a kind of method for preparing vinyl ester resin, specifically comprises:

[0093] Get 400g epoxy equivalent and be that the bromine content of 400g / mol is 48% brominated epoxy resin (Changchun Resin Factory Co., Ltd., BEB400 type resin), be warming up to 105 ℃ and feed air 10%+nitrogen 90% (volume percentage ), to which 2.4g of tetradecylbenzylphosphorous chloride, 1.6g of ethyl propyl phosphite, 2.4g of hydroquinone were added successively, and 43g of methacrylic acid was added dropwise to carry out the ring-opening reaction;

[0094] After the acid value is 0KOH mg / g, add 73g of adipic acid.

[0095] When the acid value is below 190KOH mg / g, add 270g of novolac epoxy resin (Changchun Resin Factory Co., Ltd., PNE177 resin) with a relative molecular weight of 540.

[0096] When the acid value is reacted below 5KOH mg / g, 86g of methacrylic acid is added dropwise.

[0097]When the acid value was reacted to 10-15KOH mg / g, the temperature ...

Embodiment 2

[0099] The present embodiment provides a kind of method for preparing vinyl ester resin, specifically comprises:

[0100] Get 400g epoxy equivalent and be the brominated epoxy resin EX-48 (Changchun Resin Factory Co., Ltd., BEB400 type resin) of 400g / mol epoxy equivalent, be warming up to 105 ℃ and feed air 10%+nitrogen 90% (volume percentage) Mixed gas, 2.4g of decylbenzylphosphorous chloride, 1.6g of methyl ethyl phosphite, 2.4g of hydroquinone were added successively therein, and 43g of methacrylic acid was added dropwise to carry out the ring-opening reaction;

[0101] After the acid value is 0KOH mg / g, add 73g of adipic acid.

[0102] When the acid value is below 190KOH mg / g, add 270g of novolac epoxy resin (Changchun Resin Factory Co., Ltd., PNE177 resin) with a relative molecular weight of 540.

[0103] When the acid value is reacted below 5KOH mg / g, 86g of methacrylic acid is added dropwise.

[0104] When the acid value was reacted to 10-15KOH mg / g, the temperature w...

Embodiment 3

[0106] The present embodiment provides a kind of method for preparing vinyl ester resin, specifically comprises:

[0107] Get 400g epoxy equivalent and be the brominated epoxy resin EX-48 (Changchun Resin Factory Co., Ltd., BEB400 type resin) of 400g / mol epoxy equivalent, be warming up to 105 ℃ and feed air 10%+nitrogen 90% (volume percentage) To the mixed gas, 2.4g of tetradecylbenzylphosphorus chloride, 1.6g of ethyl propyl phosphite, 2.4g of hydroquinone were successively added, and 36g of acrylic acid was added dropwise to carry out the ring-opening reaction;

[0108] After the acid value is 0KOH mg / g, add 59.0 g of succinic acid.

[0109] When the acid value is below 190KOH mg / g, add 270g of novolac epoxy resin (Changchun Resin Factory Co., Ltd., PNE177 resin) with a relative molecular weight of 540.

[0110] When the acid value is reacted below 5KOH mg / g, 72g of acrylic acid is added dropwise.

[0111] When the acid value was reacted to 10-15KOH mg / g, the temperature w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com