810MPa grade high-performance weather resistant bridge steel composite welding seam liner pasting single welded butt method

A compound welding seam, 810mpa technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of lower joint performance, large heat-affected zone of weld seam, etc., achieve excellent crack resistance, weld deposit metal The effect of less filling amount and excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

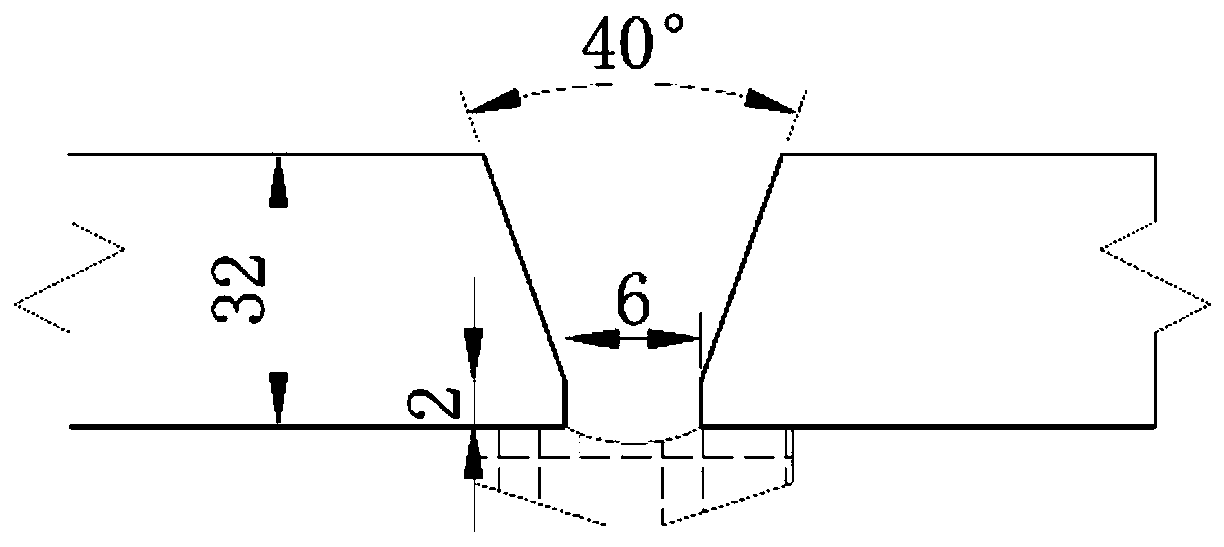

[0039] 1) The base steel type is Q690qENH, its yield strength ReL≥690MPa, tensile strength Rm≥810MPa, elongation A≥14%, -40℃ impact energy KV 2 ≥120J; equal-thickness bridge steel with plate thickness combination of 32mm+32mm;

[0040] The size of the test plate is 800mm×300mm×32mm;

[0041] 2) The groove adopts a single-sided V-shaped groove, the groove angle is 40°, the blunt edge is 2mm, and the gap is 6mm;

[0042] Welding material matching: XY-ER80QNH welding wire is used as the gas shielded welding wire for bottoming, the diameter of the welding wire is Ф1.2mm, and the argon-rich gas is protected, and the composition of the argon-rich gas is 80% Ar+20% CO2 , the mechanical properties of the deposited metal are Rel is 746MPa, Rm is 833MPa, A is 17.5%, -40℃KV 2 The impact energy is 79J;

[0043] Submerged arc automatic welding uses XY-S80QNH welding wire with a diameter of Ф4.0mm and XY-AF85QNH flux combination. The mechanical properties of the deposited metal are Rel is...

Embodiment 2

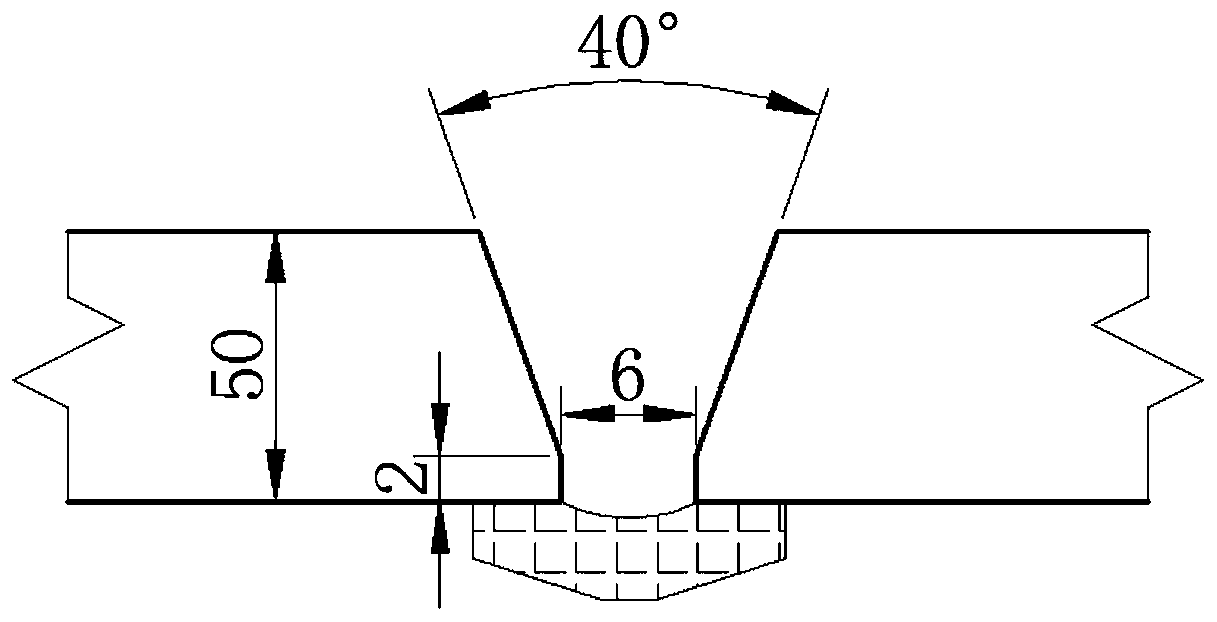

[0049] 1) The base steel type is Q690qENH, its yield strength ReL≥690MPa, tensile strength Rm≥810MPa, elongation A≥14%, -40℃ impact energy KV 2 ≥120J; equal-thickness bridge steel with plate thickness combination of 50mm+50mm;

[0050] The size of the test plate is 800mm×300mm×50mm;

[0051] 2) The groove adopts a single-sided V-shaped groove, the groove angle is 40°, the blunt edge is 2mm, and the gap is 6mm;

[0052] Welding material matching: XY-ER80QNH welding wire is used as the gas shielded welding wire for bottoming, the diameter of the welding wire is Ф1.2mm, and the argon-rich gas is protected, and the composition of the argon-rich gas is 80% Ar+20% CO 2 , the mechanical properties of the deposited metal are Rel is 746MPa, Rm is 833MPa, A is 17.5%, -40℃KV 2 The impact energy is 79J;

[0053] Submerged arc automatic welding uses XY-S80QNH welding wire with a diameter of Ф4.0mm and XY-AF85QNH flux combination. The mechanical properties of the deposited metal are Rel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com