Pole piece edge burr cleaning nozzle and device with same

An edge and pole piece technology, which is applied in the field of pole piece edge burr cleaning nozzles and devices containing the nozzle, can solve the problems of pole piece edge burrs that cannot be removed, battery short circuit, and burrs, so as to improve battery yield and improve battery yield. Safety, the effect of reducing the K value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

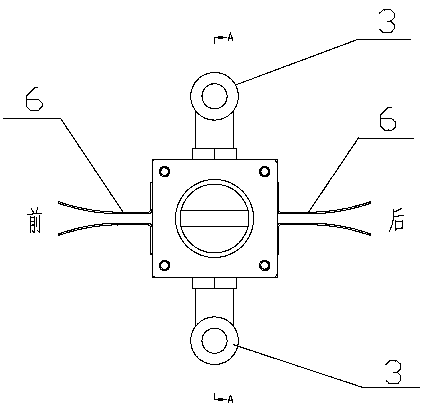

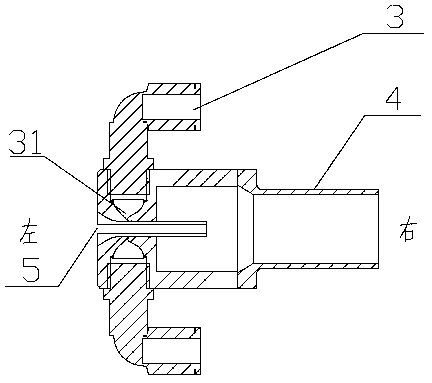

[0031] A nozzle for cleaning the burr on the edge of a pole piece, characterized in that it includes an upper plate 1, a lower plate 2, two air pipes 3 and a vacuum pipeline 4, the upper plate 1 and the lower plate 2 are all horizontally arranged and the upper plate 1 and the lower plate There is a gap 5 between the two, and the two air pipes 3 are installed on the upper plate 1 and the lower plate 2 respectively, and the nozzles 31 of the two air pipes are respectively located on the lower surface of the upper plate 1 and the upper surface of the lower plate 2 and are oppositely arranged. The two air pipes 3 are connected with the air pump, the left end of the vacuum pipe 4 is connected with the right end of the gap 5, and the right end of the vacuum pipe 4 is connected with a vacuum machine.

[0032] Further, the pole piece edge cleaning spray head also includes four guide pieces 6, and the four guide pieces 6 are installed horizontally on the front side and the back side of ...

specific Embodiment approach 2

[0040] A pole piece edge burr cleaning device comprising the pole piece edge burr cleaning nozzle described in Embodiment 1, including a guide column 7, two sliders 8 and two pole piece edge burr cleaning nozzles, two described The burr cleaning nozzles on the edge of the pole piece are arranged oppositely and installed on two sliders 8 respectively. The tape running directions of the column 7 and the pole piece 9 are perpendicular to each other, and both ends of the guide column 7 are fixed on the external fixing member.

[0041] Further, the pole piece edge deburring device further includes bolts, and the bolts pass through the threaded holes provided on the slider 8 to fix the slider 8 on the guide column.

[0042] Specific working principle:

[0043] During the transportation process, the pole piece 9 passes through the gap 5 between the upper plate 1 and the lower plate 2 from between the two guide pieces 6, and the air pump transports high-pressure gas (compressed air) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com