A ceramic tile screening and polishing integrated processing device

A processing device and ceramic tile technology, which is applied to metal processing equipment, machine tools suitable for grinding workpiece edges, grinding heads, etc., can solve problems such as low work efficiency, manual collection, and inability to remove tiles, so as to achieve rapid grinding and polishing, and solve burrs Defects, the effect of fast sorting without cascading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

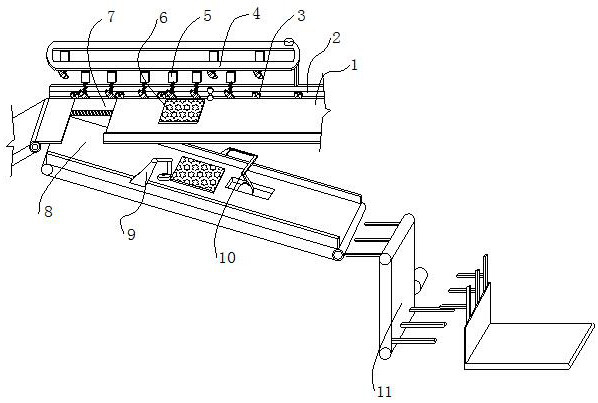

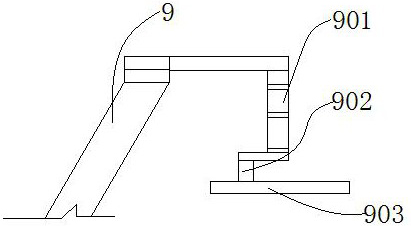

[0035] see Figures 1 to 10 A schematic diagram of a planar structure and a schematic diagram of a three-dimensional structure of a ceramic tile screening and polishing integrated processing device.

[0036] A ceramic tile screening and polishing integrated processing device, including a picking mechanism, a polishing mechanism, a limit mechanism and a recycling mechanism, the picking mechanism is located above the polishing mechanism, the limiting mechanism and the recycling mechanism, and the polishing mechanism, the limiting mechanism and the recycling mechanism sorted from left to right;

[0037] The picking mechanism includes a feeding conveyor belt 1, a feeding guide rail 2, a pressing block transportation track 4, and a telescopic pressing block 5. Evenly distributed ceramic tiles 6 are placed on the feeding conveyor belt 1, and the feeding guide rail 2 is movable and inlaid with limited blocks. 3. A telescopic binder 5 is inlaid on the side of the binder transport tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com