Carbon dioxide separation membrane and production method therefor

A carbon dioxide and separation membrane technology, applied in the direction of separation methods, chemical instruments and methods, gardening methods, etc., can solve the problems of no ionic liquid, etc., achieve the effects of suppressing stickiness, excellent operability, and realizing miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0087] The method for producing such a porous film of thermoplastic resin is not particularly limited, and conventional methods, such as a method using phase separation of a resin solution, a method of stretching a resin film, or irradiating a resin film with high-energy rays such as α-rays, can be used. method etc. to prepare.

[0088] In addition, in order to adjust the wettability (or contact angle) of the liquid (A) containing the ionic liquid, the IL-incompatible porous layer (B) can be subjected to a conventional surface treatment (for example, JP-A-6-9810 The treatment described in , that is, the treatment of attaching a cross-linked body derived from an ethylenically unsaturated monomer having a fluoroalkyl group, etc.).

[0089] Commercially available products can be used as the IL-incompatible porous layer (B), and examples thereof include "C-pore" manufactured by Ube Maxell Co., Ltd., "U-Pore" manufactured by Ube Industries Co., Ltd., and "U-Pore" manufactured by Me...

Embodiment 1

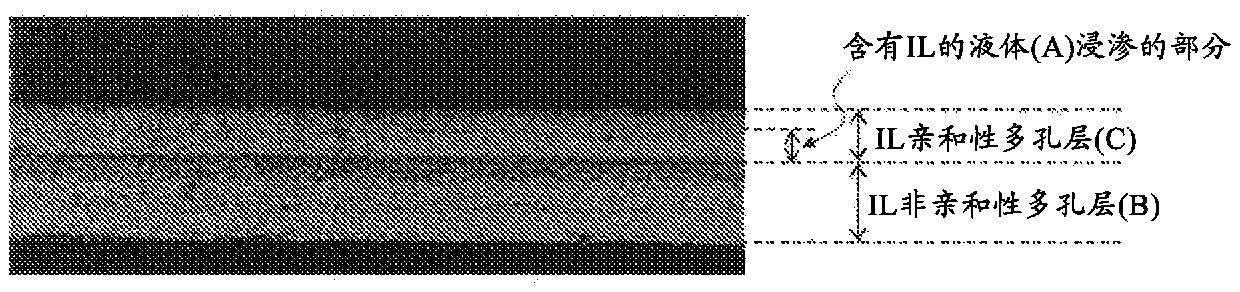

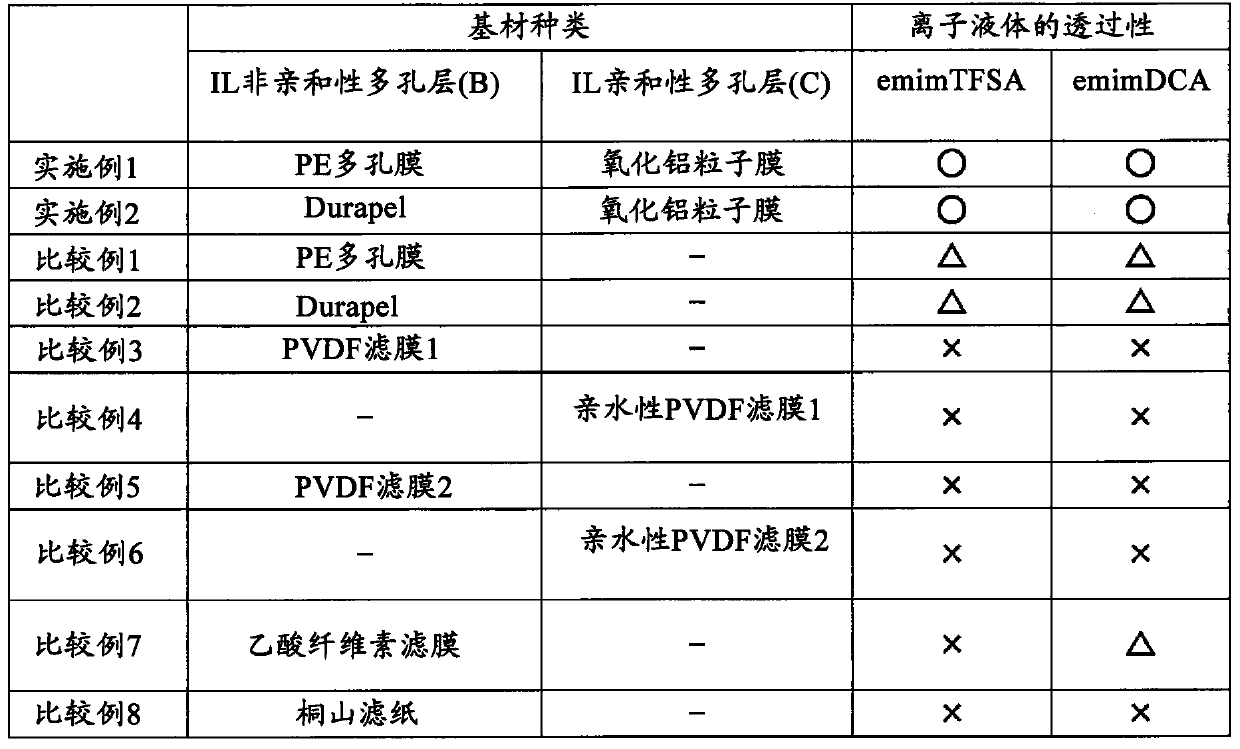

[0161] The above-mentioned alumina particles were mixed with water to prepare an alumina particle dispersion (alumina particle slurry) having a concentration of 8 to 10% by weight. On the PE porous membrane as the IL non-affinity porous layer (B), the obtained alumina particle slurry was coated by wire bar coating, and dried at 100°C for 1 minute to form an IL affinity layer (B). And the porous layer (C). The alumina particle slurry was applied so that the dried IL-affinity porous layer (C) had a thickness of 5 μm. The permeability of the ionic liquid was evaluated using the IL-free laminate. It should be noted that the ionic liquid was dripped on the IL-affinity porous layer (C) side of the fixed IL-free laminate, and on the opposite side of the dripped surface (IL-non-affinity porous layer (B) side) was decompressed.

Embodiment 2

[0163] In addition to adding 1% by weight of isopropyl alcohol (IPA) to the aluminum oxide particle dispersion liquid, and using Durapel as the IL non-affinity porous layer (B), the same as the example 1 A laminate not containing IL was prepared in the same manner, and the permeability of the ionic liquid to the obtained laminate not containing IL was evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com