A kind of cold seal adhesive and its preparation method and a kind of preparation method of adhesive tape

An adhesive and cold-close type technology, which is applied in the direction of adhesive types, ester copolymer adhesives, film/sheet adhesives, etc., can solve the problem of limited effect, uneven monomer concentration, sticky Solve problems such as uneven surface viscosity of the joint belt, achieve the effects of uniform viscosity distribution and thickness, improved heat resistance, and improved high-temperature adhesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

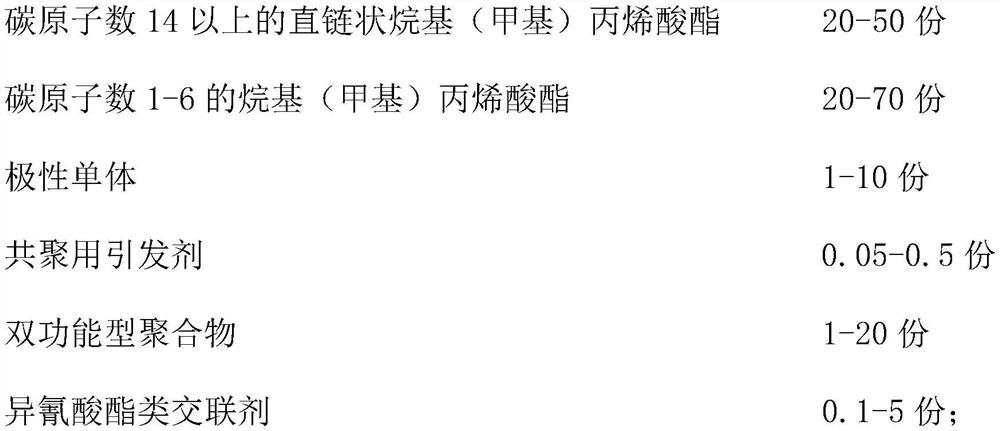

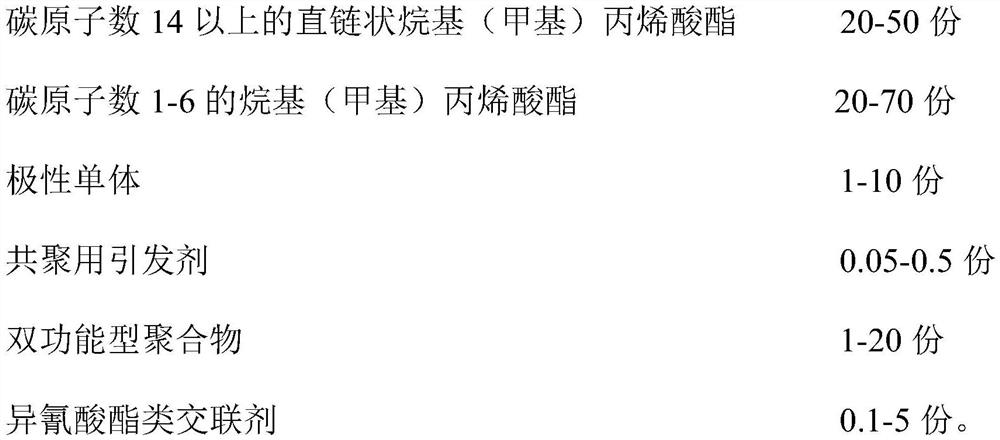

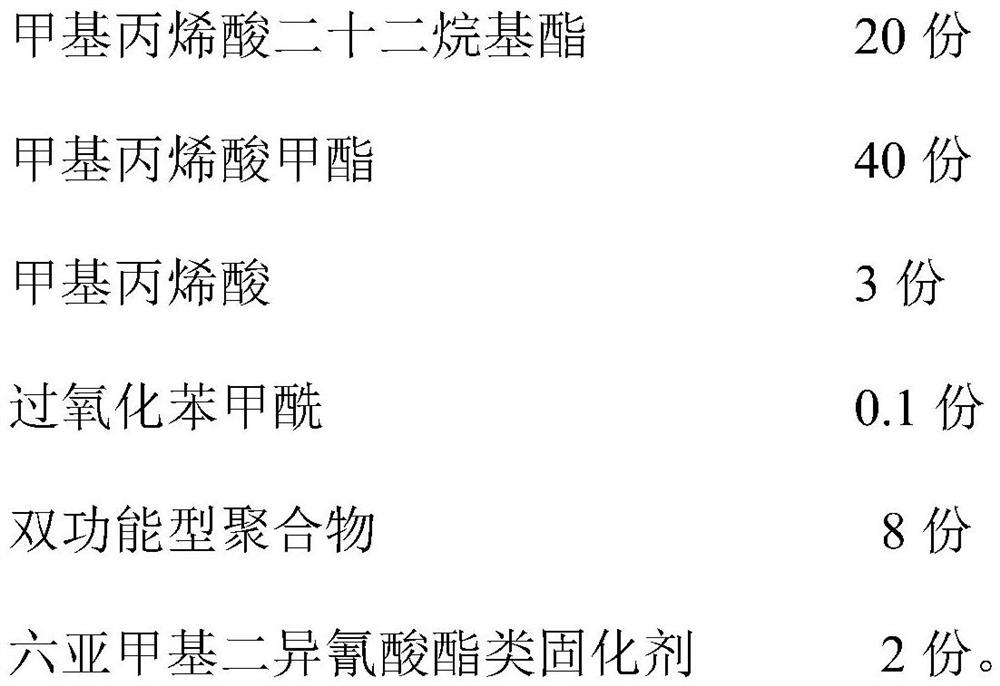

[0024] A cold-sealing adhesive, comprising the following raw materials in parts by mass:

[0025]

[0026] A kind of preparation method of cold seal type adhesive, comprises the following steps:

[0027] Step 1, add 20 parts of behenyl methacrylate, 40 parts of methyl methacrylate and 3 parts of methacrylic acid in 20 parts of toluene, and stir evenly in N2 bubbling, add 0.1 part of initiator Oxidize benzoyl to obtain a crystalline prepolymer with a side chain;

[0028] Step 2: Add 8 parts of bifunctional polymer and 2 parts of hexamethylene diisocyanate curing agent to the crystalline prepolymer with side chains prepared in Step 1, and stir well to obtain the cold-seal adhesive mixture.

[0029] The hydroxyl value of the bifunctional polymer is 35 mg KOH / g, and the molecular weight is below 5000.

[0030] An adhesive tape made of cold seal adhesive, made by the following method: add 1 part of 2,2-diethoxybenzophenone to the adhesive in the dark, mix it evenly Coated on...

Embodiment 2

[0032] A cold-sealing adhesive, comprising the following raw materials in parts by mass:

[0033]

[0034] A kind of preparation method of cold seal type adhesive, comprises the following steps:

[0035] Step 1, add 30 parts of stearyl methacrylate, 40 parts of methyl methacrylate and 5 parts of (meth)acrylic acid-2-2 hydroxypropyl ester in 20 parts of toluene, and stir in N2 bubbling Evenly, add 0.1 part of initiator azobisisobutyronitrile to obtain a crystalline prepolymer with a side chain;

[0036] Step 2: Add 10 parts of bifunctional polymer and 2.5 parts of toluene diisocyanate curing agent to the crystalline prepolymer with side chains prepared in Step 1, and stir thoroughly to obtain a cold-close adhesive.

[0037] The hydroxyl value of the bifunctional polymer is 30 mg KOH / g, and the molecular weight is below 5000.

[0038] A kind of adhesive tape made of cold seal adhesive is made by the following method: add 0.2 part of photoinitiator TPO and 0.1 part of photoi...

Embodiment 3

[0040] A cold-sealing adhesive, comprising the following raw materials in parts by mass:

[0041]

[0042] A kind of preparation method of cold seal type adhesive, comprises the following steps:

[0043] Step 1, add 30 parts of myristyl methacrylate, 60 parts of ethyl methacrylate and 5 parts of (meth)acrylic acid-2-2 hydroxypropyl ester in 20 parts of toluene, and stir in N2 bubbling Evenly, add 0.15 parts of initiator azobisisobutyronitrile to obtain a crystalline prepolymer with a side chain;

[0044] Step 2: Add 8 parts of bifunctional polymer and 8 parts of toluene diisocyanate curing agent to the crystalline prepolymer with side chains prepared in Step 1, and stir thoroughly to obtain a cold-close adhesive.

[0045] The hydroxyl value of the bifunctional polymer is 35 mg KOH / g, and the molecular weight is below 5000.

[0046] A kind of adhesive tape made of cold seal adhesive is made by the following method: add 0.15 parts of photoinitiator TPO to the adhesive in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com