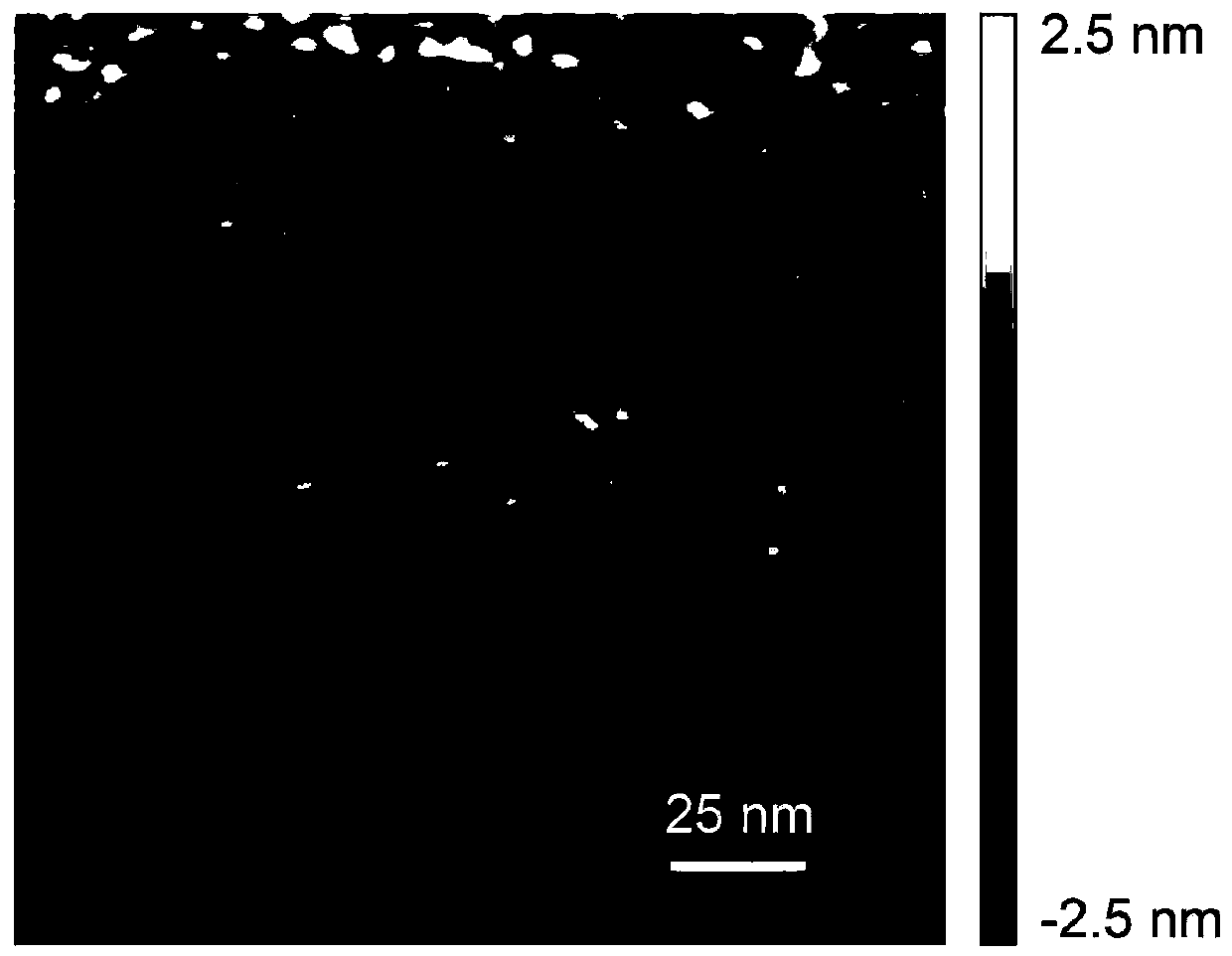

Molybdenum disulfide with atomic layer steps and preparation method thereof

A molybdenum disulfide and atomic layer technology, applied in the fields of molybdenum sulfide, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of insufficient boundary of molybdenum disulfide and low catalytic performance of hydrogen evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

[0027] The concrete steps of this embodiment are as follows:

[0028] ① Pretreatment of raw materials: use molybdenum disulfide with a purity of 99.99%, grind; perform ultrasonic peeling in a warm water bath, peeling time is 2 hours, and the temperature of the water bath is 60°C;

[0029] ② Centrifugal cleaning: Disperse the sample obtained by stripping in step ① in deionized water, then place it in a centrifuge and centrifuge at a speed of 8000 rpm; pour off the supernatant, and redisperse the cleaned sample in deionized water , repeat the above operation 3 times; dry in a blast drying oven at a drying temperature of 40°C for 2 hours;

[0030] ③ Prepare the dispersion solution: add 25 ml of deionized water to the beaker; add 20 ml of ethanol to the beaker; add 5 ml of PVP to the beaker; stir the mixed solution evenly with a glass rod, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com