Double-sided amphiphilic carrier, as well as preparation method and application thereof

An amphiphilic and carrier technology, which is applied to the double-sided amphiphilic carrier and its preparation and application fields, can solve the problems of neglecting the influence and the like, and achieve the effects of improving catalytic activity, improving environmental adaptability and expanding production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

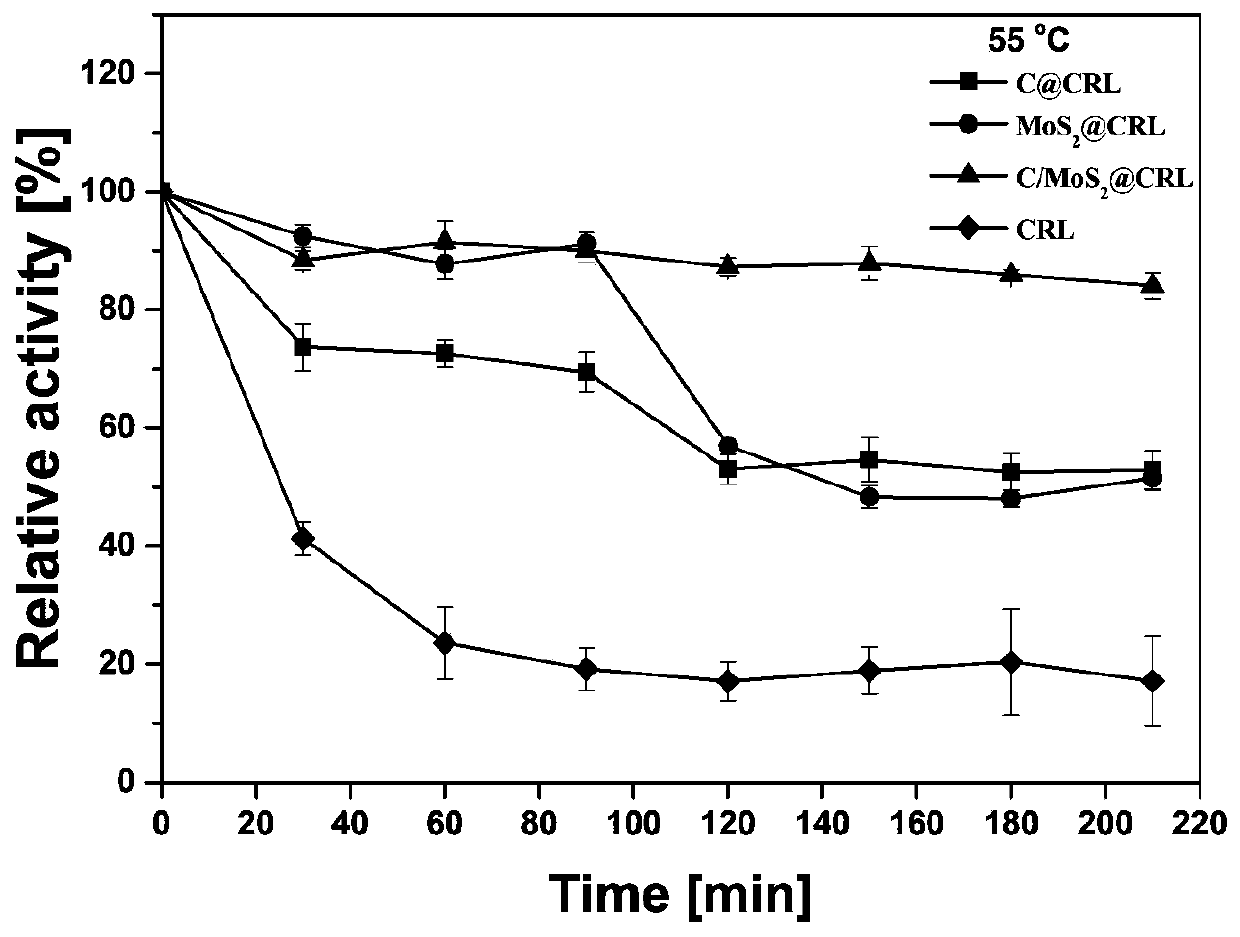

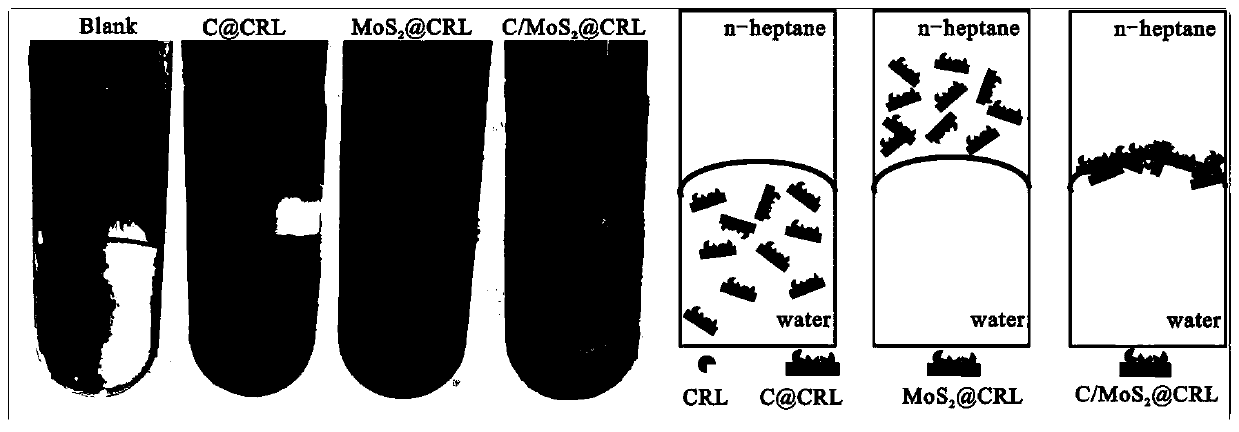

Method used

Image

Examples

Embodiment 1

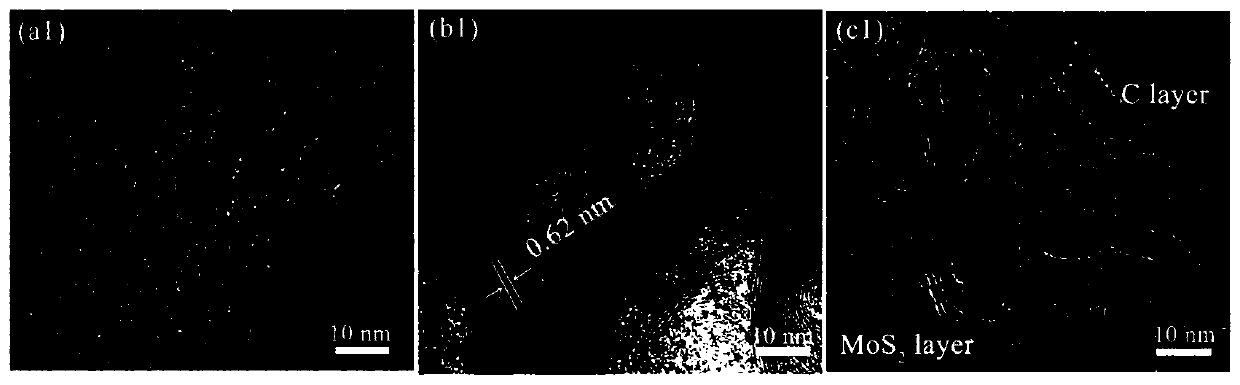

[0033] C / MoS 2 Preparation of carrier material:

[0034] After fully mixing 4g of dicyandiamide and 0.1g of glucose, place it in a tube furnace for calcination. The calcination procedure is to raise the temperature from room temperature to 600°C and then to 800°C in a nitrogen atmosphere, keep it warm for 1 hour, and drop to room temperature to obtain C Material.

[0035] Disperse 0.165g of material C in 165ml of UP water and ultrasonically disperse for 0.5h, then fully dissolve 0.75g of sodium molybdate in the above aqueous dispersion of C, add 3.125g of L-cysteine and ultrasonically disperse for 1h, and place the above mixed solution Put it in a reaction kettle, and react at 220°C for 24h. After the reaction, it will be cooled to room temperature, washed with ethanol for several times, and then dried in a vacuum oven at 60°C to obtain C / MoS 2 . The resulting C / MoS 2 C:MoS in materials 2 The mass ratio is 1:3.

[0036] Preparation of C / MoS 2Immobilized enzyme: 1) Dis...

Embodiment 2

[0043] C / MoS 2 Preparation of carrier material:

[0044] Put 4g of dicyandiamide in a tube furnace for calcination. The calcination procedure is to raise the temperature from room temperature to 550°C in a nitrogen atmosphere and keep it for 4h, then cool down to room temperature naturally. The obtained carbon nitride raw material is placed in an aqueous solution of glucose , sonicated for 4 h and then freeze-dried. The freeze-dried mixture was placed in a tube furnace, heated from room temperature to 800 ° C under a nitrogen atmosphere and kept for 1 h, and then cooled to room temperature to obtain carbon materials.

[0045] Then fully dissolve 0.165g of sodium molybdate in the water dispersion of C, add 0.11g of thiourea and sonicate for 1h, put the above mixed solution in the reaction kettle, and react at 240°C for 18h. After washing with ethanol several times, dry in a vacuum oven at 60°C to obtain C / MoS 2 . The resulting C / MoS 2 C:MoS in materials 2 The mass ratio is...

Embodiment 3

[0048] C / MoS 2 Preparation of carrier material:

[0049] After fully mixing 4g of melamine and 0.5g of glucose, place it in a tube furnace for calcination. The calcination procedure is to raise the temperature from room temperature to 650°C and then to 850°C in a nitrogen atmosphere, keep it warm for 1 hour, and then lower it to room temperature to obtain material C.

[0050] Dissolve 0.6g of ammonium thiosulfate in 20ml of UP water and disperse ultrasonically for 0.5h, then disperse the prepared C material solution in the above solution, disperse ultrasonically for 1h, put the above mixed solution in a reaction kettle, and react at 240°C After 18 hours, after the reaction was completed, it was cooled to room temperature, washed with ethanol for several times, and then dried in a vacuum oven at 60°C to obtain C / MoS 2 . The resulting C / MoS 2 C:MoS in materials 2 The mass ratio is 1:3.

[0051] Preparation of C / MoS 2 Immobilized enzyme: 1) 3g Rhizomucor miehei lipase (RML)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com