Nanosecond laser ablation and chemical thermal decomposition compound preparation method for stainless steel surface super-hydrophobic micro-nano structures

A technology of micro-nano structure and laser ablation, which is applied in the direction of nanotechnology for materials and surface science, laser welding equipment, and devices for coating liquid on the surface, etc. It can solve the problems of reducing surface energy, high cost, and stainless steel superhydrophobic Long preparation period of micro-nano structure and other issues, achieve low cost, low cost, and shorten the preparation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

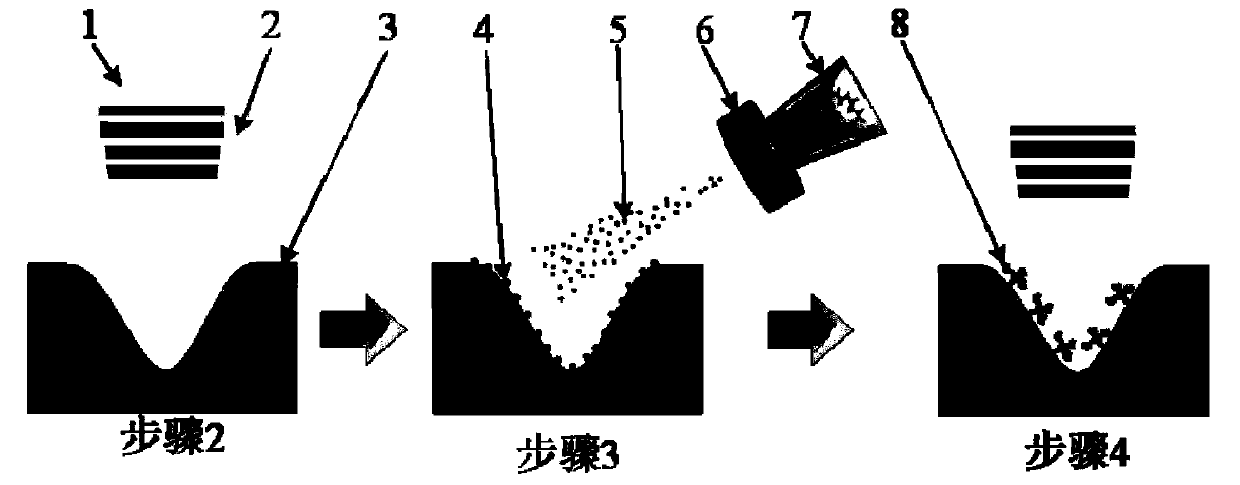

[0037] As introduced in the background art, the current methods for preparing surface superhydrophobic micro-nano structures have the problems of long cycle time or environmental pollution. Therefore, the present invention proposes a composite preparation method of nanosecond laser ablation and chemical thermal decomposition of a super-hydrophobic micro-nano structure on the surface of stainless steel, comprising the following steps:

[0038] Step (1): pretreatment, the stainless steel sample is ultrasonically cleaned with absolute ethanol to remove surface oil and impurities, and air-dried at room temperature.

[0039] Step (2): Place the cleaned and air-dried workpiece in step 1 on the infrared nanosecond laser processing platform; adjust the laser focus to the upper surface of the workpiece, and carry out equidistant linear scanning.

[0040] Step (3): Configure ethanol solution of stearic acid, pour the solution into the ultrasonic atomizer, start the ultrasonic atomizer,...

Embodiment 1

[0050] (1) Pretreatment, the 10mm×10mm×2mm stainless steel sample was ultrasonically cleaned in absolute ethanol for 5 minutes to remove surface oil and impurities, and air-dried at room temperature.

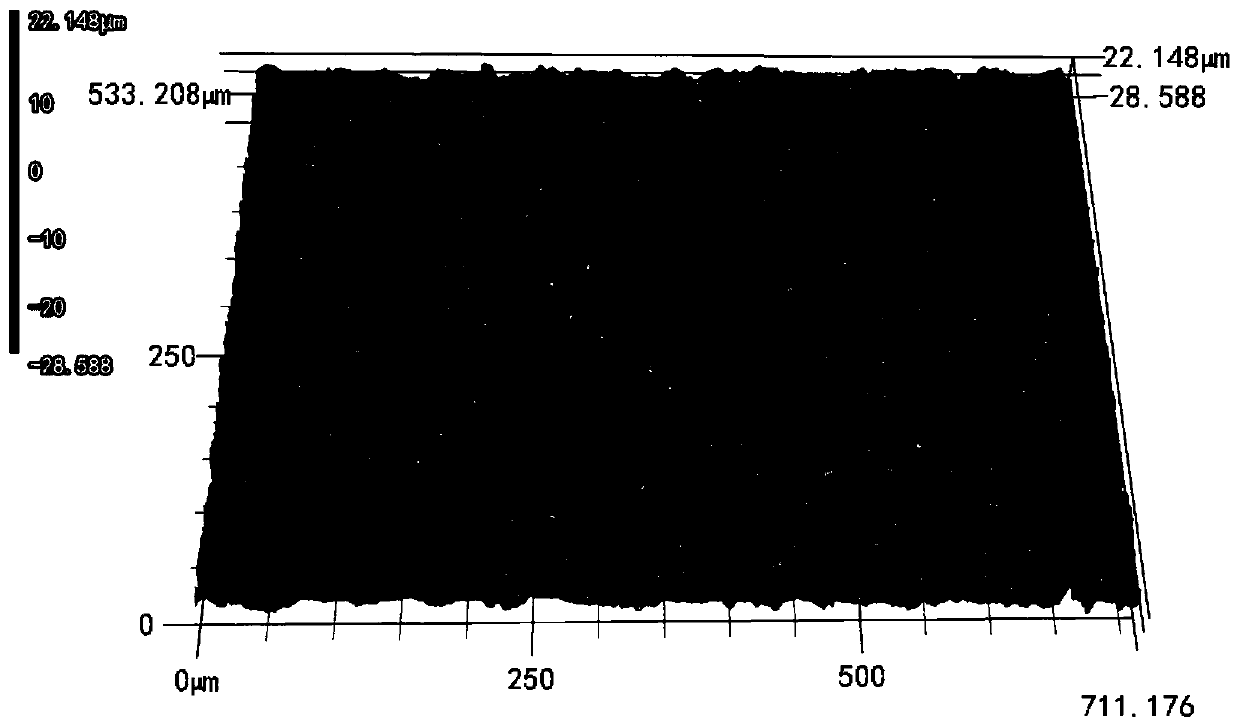

[0051] (2) Infrared nanosecond laser ablation for the first time: see attached figure 1 , place the pretreated workpiece on the infrared nanosecond laser processing platform; adjust the laser focus to the upper surface of the workpiece, set the average laser power to 20W, the pulse frequency to 100kHz, the scanning speed to 2000mm / min, and the laser scanning distance to 25μm .

[0052] (3) Stearic acid particle deposition: see attached figure 1 , use the ultrasonic atomization device to atomize the absolute ethanol solution of stearic acid with a mass ratio of 3%, and spray a layer of stearic acid ethanol solution micro-droplets evenly on the surface of the sample. The moving speed of the ultrasonic atomization device is 2000mm / min, 30mm away from the surface of the workpiece,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com