Modular clamping system

A modular, clamping device technology, applied in the direction of clamping, large fixed members, support, etc., can solve the problem that the clamping device is not suitable for applications with high stamping pressure tolerance, and achieve the effect of avoiding lateral force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

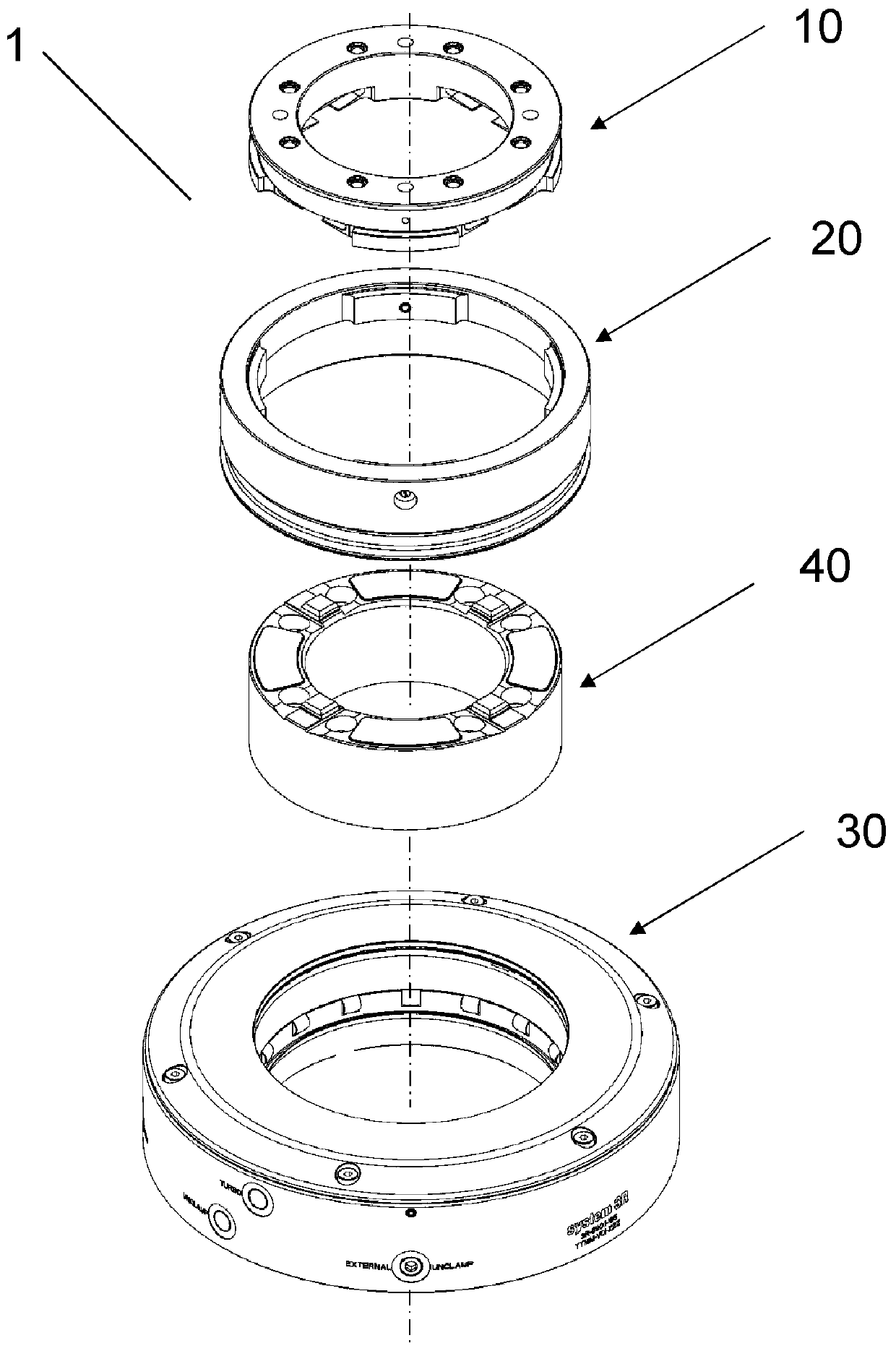

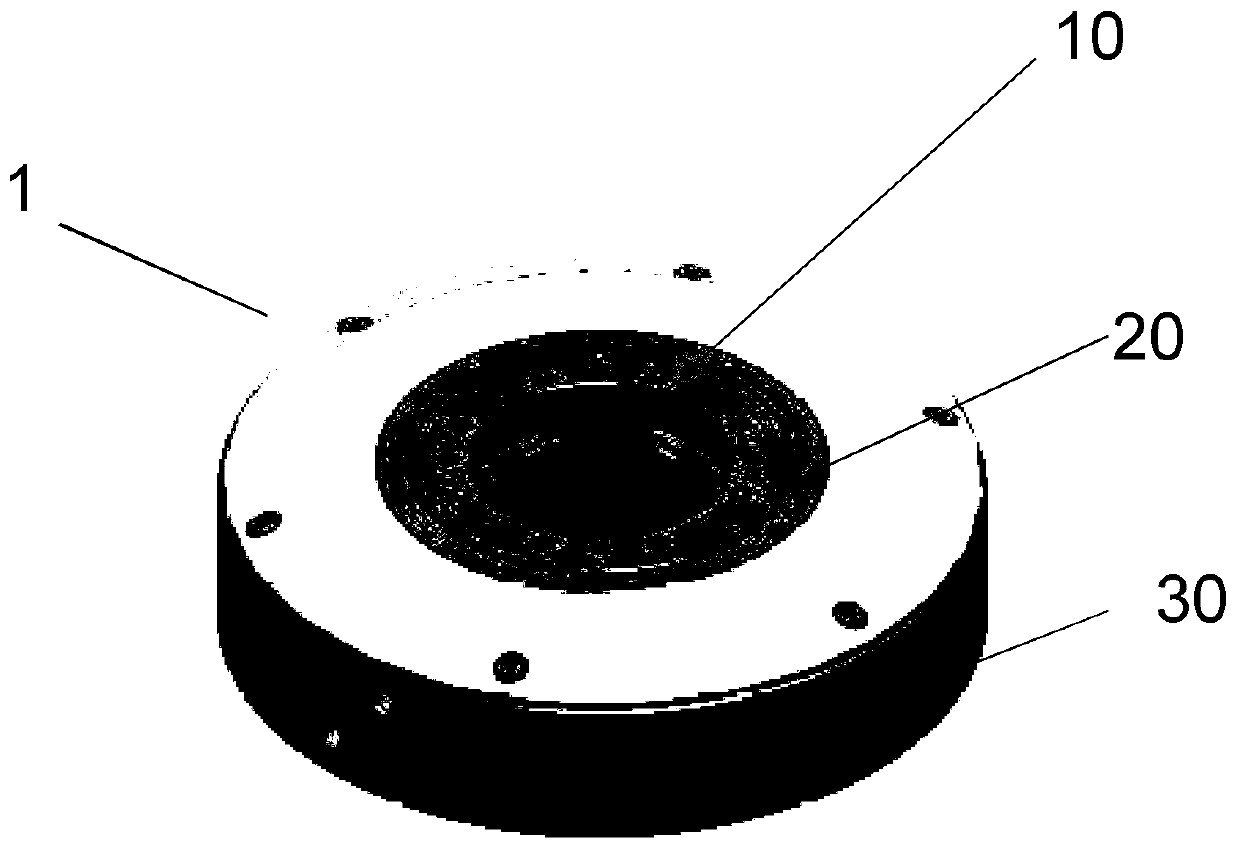

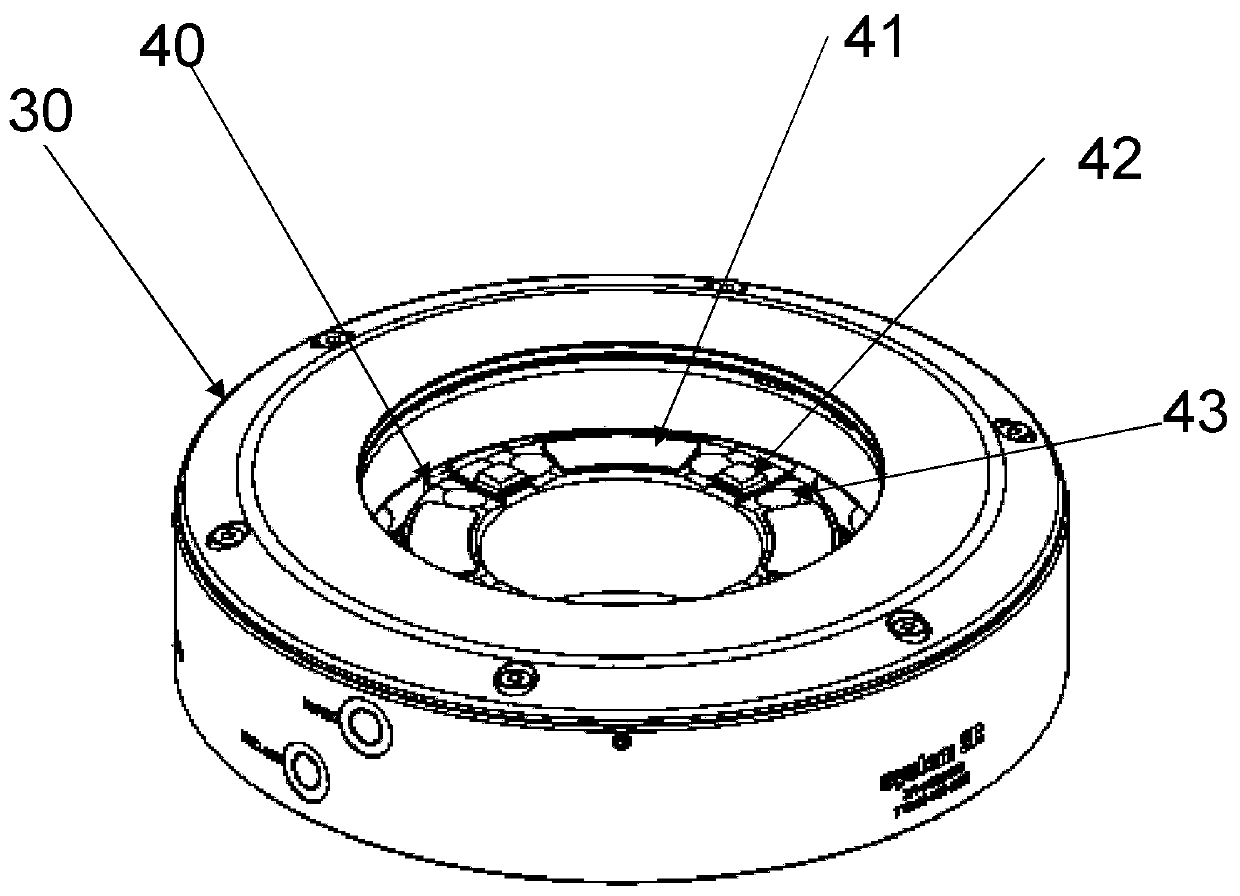

[0039] figure 1 A modular clamping system 1 is shown comprising a bracket 10 , a tubular part 20 , a chuck part 40 and a clamping unit 30 .

[0040] figure 2 The bracket 10 and the tubular portion 20 are shown in an exploded view. The carriage is provided with an x-y reference for positioning in the x-y direction and a z reference in the z direction. In this embodiment, the x-y reference is formed by four pairs of elastic tongues 17 . However, other variants, for example in the form of grooves, are also suitable for the invention. A flat surface 16 on the underside of the bracket forms the z-reference.

[0041] The bracket is mountable into the tubular portion and connected to the tubular portion by a first connection mechanism. exist figure 2 In the embodiment shown in , the bracket is provided with four first bayonet wings 12 for engaging in four corresponding second bayonet wings 22 provided on the tubular portion. The first bayonet wing and the second bayonet wing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com