Method for preparing theaflavin

A technology for theaflavin and tea liquid, applied in separation methods, chemical instruments and methods, solid solvent extraction and other directions, can solve the problems of difficulty, serious environmental pollution, low product purity, etc., and achieves reduction of production cost and fermentation synthesis rate. High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

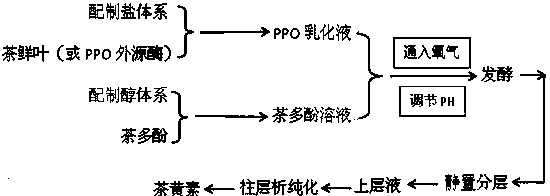

Image

Examples

Embodiment 1

[0028] A method for preparing theaflavins, characterized in that it comprises the steps of:

[0029] 1) Preparation of polyphenol oxidase emulsion: crush fresh tea leaves into mud, add them to the salt solution so that the amount of fresh tea leaves is 10% of the mass of the salt solution, and then add 0.02‰ of the fresh tea leaves Polyvinylpyrrolidone (PVPP), mixed and emulsified for 5 minutes, polyphenol oxidase emulsion;

[0030] The salt solution is prepared by the following method: adding (NH 4 ) 2 SO 4 to (NH 4 ) 2 SO 4 The mass concentration is 10%, stirred to (NH 4 ) 2 SO 4 Completely dissolved, (NH 4 ) 2 SO 4 High solubility in water;

[0031] 2) Preparation of tea polyphenol alcohol solution: add tea liquid to the alcohol liquid so that the amount of tea polyphenols in the tea liquid is 1% of the alcohol liquid mass, and mix evenly to obtain the tea polyphenol alcohol solution;

[0032]The alcohol solution is prepared by the following method: adding etha...

Embodiment 2

[0039] A method for preparing theaflavins, characterized in that it comprises the steps of:

[0040] 1) Preparation of polyphenol oxidase emulsion: crush pineapple, peach and mango into puree at a ratio of 1:1:1, and add it to the salt solution so that the amount of pineapple, peach and mango puree is 60% of the quality of the salt solution. %, add 0.2‰ of cross-linked polyvinylpyrrolidone (PVPP) of pineapple, peach and mango puree, mix and emulsify for 20min, polyphenol oxidase emulsion;

[0041] The salt solution is prepared by the following method: adding K in purified water 2 HPO 4 to K 2 HPO 4 The mass concentration is 50%, stirred to K 2 HPO 4 completely dissolved;

[0042] 2) Preparation of tea polyphenol alcohol solution: add commercially available tea polyphenol solution to the alcohol liquid so that the amount of tea polyphenol is 4% of the alcohol liquid mass, and mix evenly to obtain tea polyphenol alcohol solution;

[0043] The alcohol solution is prepared ...

Embodiment 3

[0049] A method for preparing theaflavins, characterized in that it comprises the steps of:

[0050] 1) Preparation of polyphenol oxidase emulsion: crush potatoes, sweet potatoes, spinach, pumpkin, and yam in the same proportion into a mixed puree, add it to the salt solution, so that the amount of the mixed puree is 30% of the mass of the salt solution, and then add 0.1‰ of cross-linked polyvinylpyrrolidone (PVPP) in fresh tea leaves or plants containing exogenous enzymes, mixed and emulsified for 10 minutes, polyphenol oxidase emulsion;

[0051] The salt solution is prepared by the following method: add NaCl to pure water until the mass concentration of NaCl is 25%, and stir until NaCl is completely dissolved;

[0052] 2) Preparation of tea polyphenol alcohol solution: add tea liquid to the alcohol liquid so that the amount of tea polyphenols in the tea liquid is 2% of the alcohol liquid mass, and mix evenly to obtain the tea polyphenol alcohol solution;

[0053] The alcoho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com