Rapid activation method of proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in fuel cells, battery electrodes, electrochemical generators, etc., can solve the problems of poor effect, speed up the reaction speed and long time on both sides of the cathode and anode, save activation cost, Shortened activation time and enhanced hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

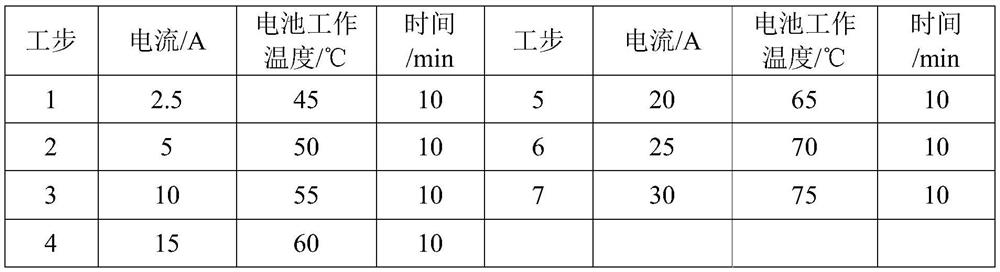

[0018] A rapid activation method of proton exchange membrane fuel cell, 5 × 5 cm 2 The newly prepared CCM film is placed in a plasma treatment device and treated according to the prior art plasma surface treatment process. The plasma treatment device is filled with argon gas, and the flow rate of argon gas is 15ml / s. The power of the plasma treatment device is 100W, The vacuum degree is 50Pa, the temperature is 40℃, and the plasma surface treatment time is 2min; after that, the treated CCM membrane is made into a proton exchange membrane fuel cell according to the existing process, and the proton exchange membrane fuel cell is connected to the battery tester. Press the following Steps to activate:

[0019] (a) First, set the battery operating temperature to 45°C, humidify, and use the metering ratio mode for the supply of reaction gas. According to hydrogen: 1.5, air: 2.5, the initial value of the output current is set to 2.5A, and the battery operating temperature is graduall...

Embodiment 2

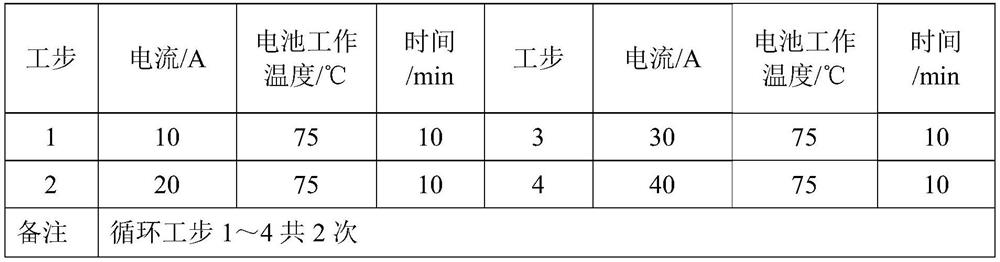

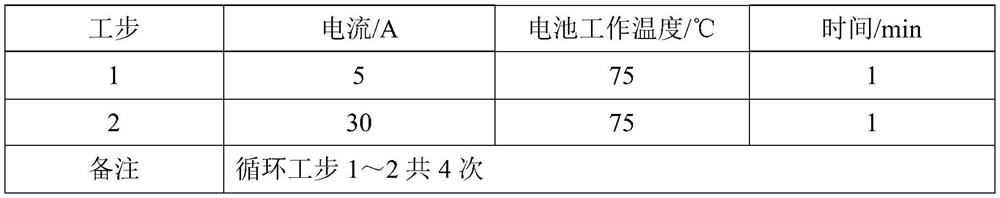

[0030] A rapid activation method of proton exchange membrane fuel cell, 4 × 4 cm 2 The newly prepared CCM film is placed in a plasma treatment device and treated according to the prior art plasma surface treatment process. The plasma treatment device is filled with argon gas, the flow rate of argon gas is 10ml / s, and the power of the plasma treatment device is 100W, The vacuum degree is 50Pa, the temperature is 40℃, and the plasma surface treatment time is 5min; then the treated CCM membrane is made into a proton exchange membrane fuel cell according to the existing process, and the proton exchange membrane fuel cell is connected to the battery tester. Press the following Steps to activate:

[0031] (a) First, set the battery working temperature to 40°C, humidify, use the fixed value mode for the supply of reaction gas, hydrogen is 500mL / min, air is 1500mL / min, the initial value of the output current is set to 1A, and the battery working temperature is gradually increased. Hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com