Preparation method and application of nano cubic bimetal selenide material

A nano-cube and bimetallic technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor cycle performance and small specific capacity of batteries, and achieve improved cycle performance and life, Improve the specific capacity of the battery and the effect of simple and controllable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of a nano-cube double metal selenide material, the steps are as follows:

[0033] Weigh 1.5g of potassium stannate and dissolve in 5mL of deionized water, weigh 1.4g of zinc sulfate and dissolve in 45mL of deionized water, mix after fully dissolving, place on a magnetic stirrer and stir at 25°C for 4 hours to obtain a white suspension The turbid liquid is centrifuged, washed with water and washed with alcohol to obtain white cubic ZnSn(OH) 6 ;

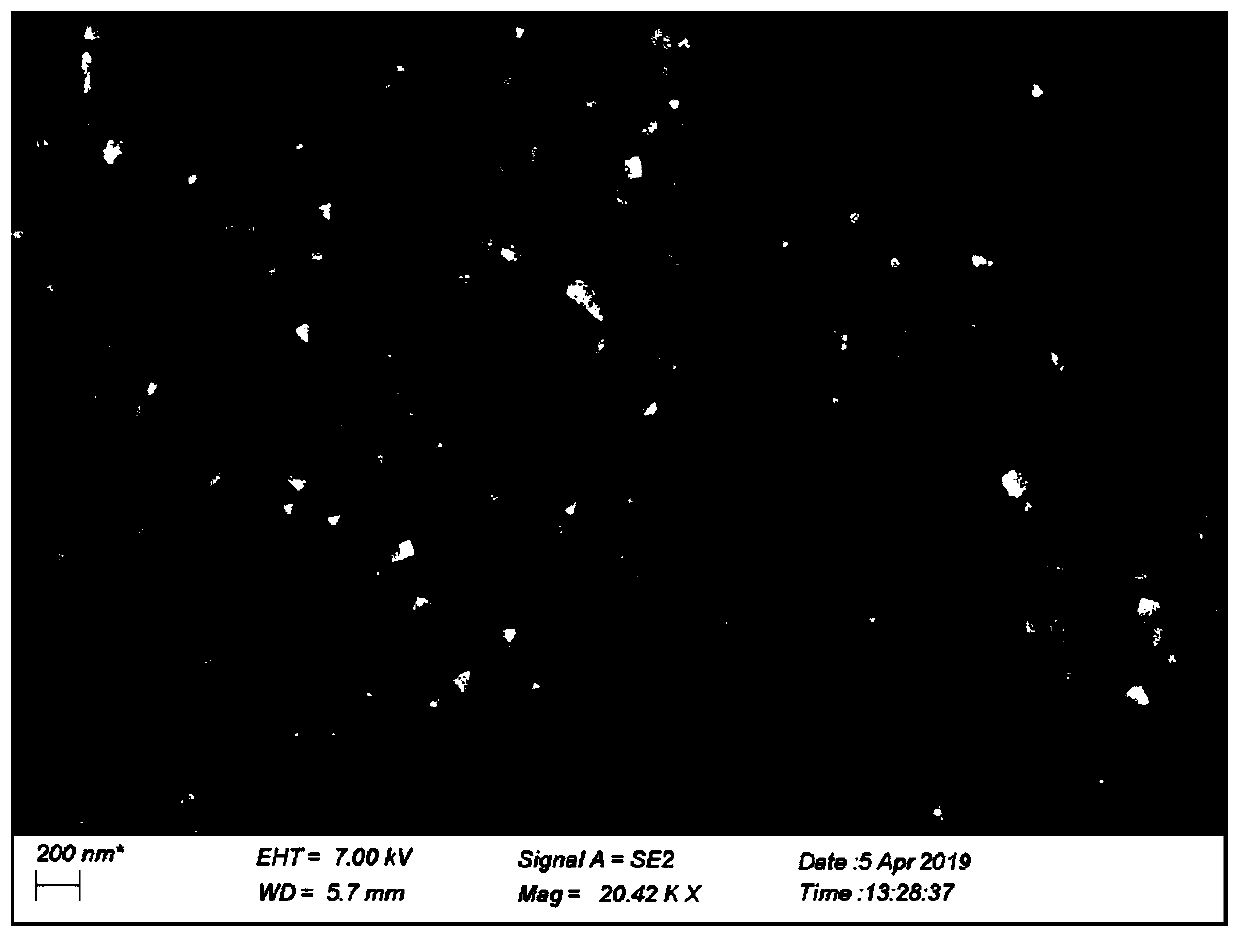

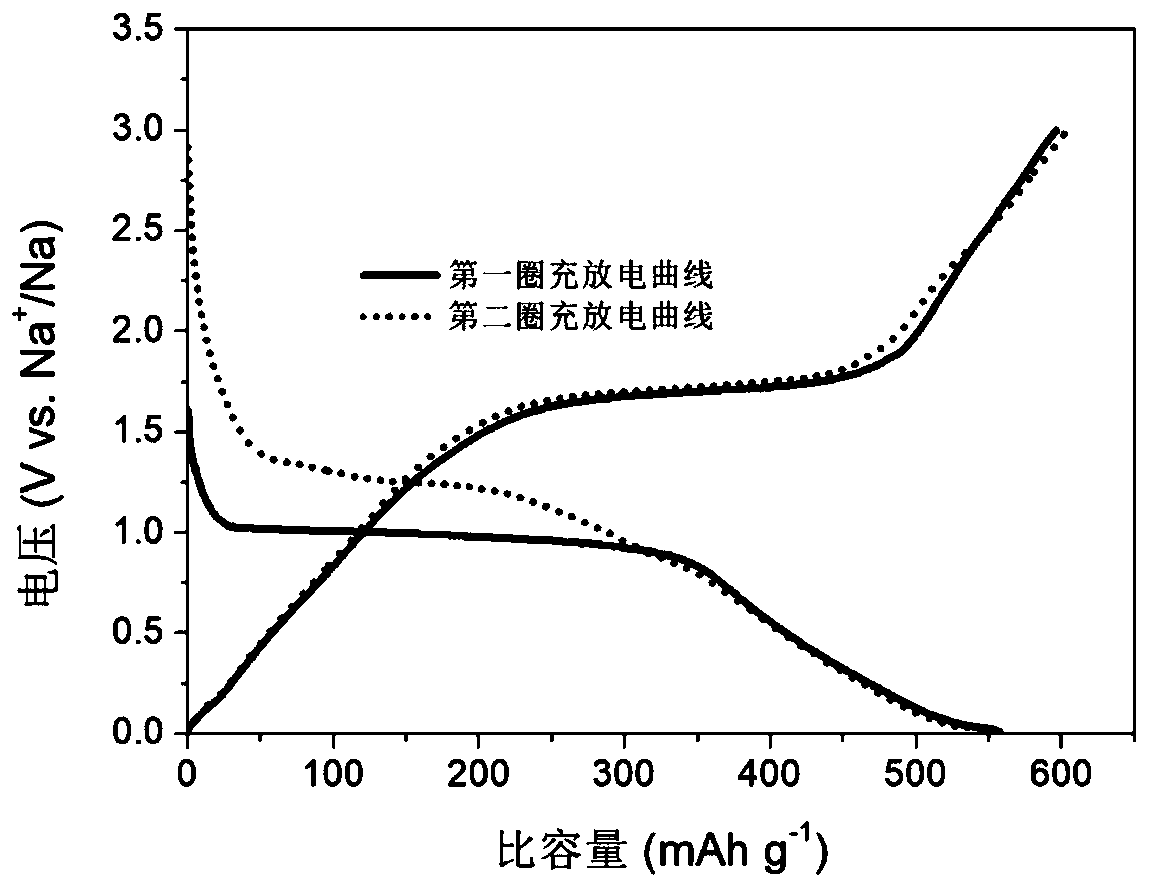

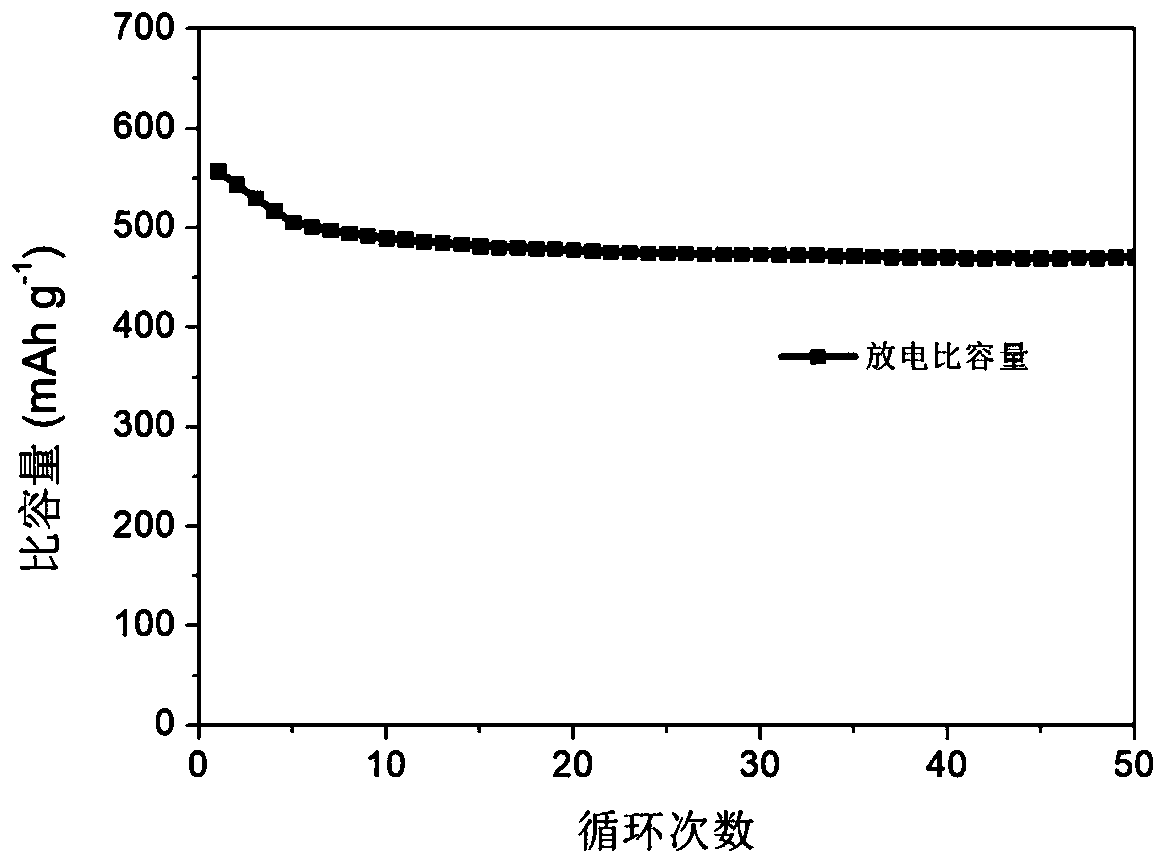

[0034] Weigh 1g of the prepared ZnSn(OH) 6 and 2g selenium powder were placed in two arks respectively, under 5% H 2 Calcination treatment in tube furnace under / 95% Ar atmosphere, heating rate 2 ℃ / min, naturally cool to room temperature after 400 ℃ of insulation 3 hours, obtain nano-cube zinc selenide material, and described nano-cube zinc selenide The tin material was characterized by scanning electron microscopy, and the specific scanning electron microscopy picture is as follows figure 1 As shown, it...

Embodiment 2

[0040] A preparation method of a nano-cube double metal selenide material, the steps are as follows:

[0041] Weigh 1.5g of copper nitrate and dissolve in 10mL of deionized water, weigh 1.4g of zinc sulfate and dissolve in 30mL of deionized water, mix after fully dissolving, place on a magnetic stirrer and stir at room temperature for 5 hours to obtain a suspension, and centrifuge , washed with water, and washed with alcohol to obtain cubic ZnCu(OH) 4 ;

[0042] Weigh 1g of the prepared ZnCu(OH) 4 and 3g selenium powder were placed in two arks respectively, in 5%H 2Calcination treatment in a tube furnace under an atmosphere of 95% Ar, the heating rate is 5°C / min, and the temperature is kept at 500°C for 2 hours, and then naturally cooled to room temperature to obtain the nano-cubic zinc-copper selenide material, which can be used as a sodium-ion battery Negative electrode materials for the preparation of sodium-ion batteries.

Embodiment 3

[0044] A preparation method of a nano-cube double metal selenide material, the steps are as follows:

[0045] Weigh nickel nitrate and zinc sulfate with a molar ratio of 0.5:1 and dissolve them in deionized water respectively. The dispersion concentrations of nickel nitrate and zinc sulfate in deionized water are both 0.15 g·mL -1 , after fully dissolving, mix evenly, place on a magnetic stirrer and stir at 10°C for 1 hour to obtain a suspension, centrifuge, wash with water, and wash with alcohol to obtain a nanocube double metal hydroxide;

[0046] Take by weighing nano cube double metal hydroxide and selenium dioxide and be dispersed in deionized water (the mol ratio of described nano cube double metal hydroxide and selenium dioxide is 0.001:1), then place polytetrafluoroethylene reactor , add sodium hydroxide and sodium borohydride to carry out selenization reaction, the reaction temperature is 150 ° C, the reaction time is 1 hour, and naturally cool to room temperature to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com