C/SiC-ZrB2 composite material and preparation method thereof

A technology of sic-zrb2 and composite materials, which is applied in the field of C/SiC-ZrB2 composite materials and its preparation, can solve the problems of uneven distribution of zirconium boride, increase of impregnation cycle, poor densification effect, etc., and achieve improved matrix densification Efficiency, improvement of densification degree, effect of improvement of densification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

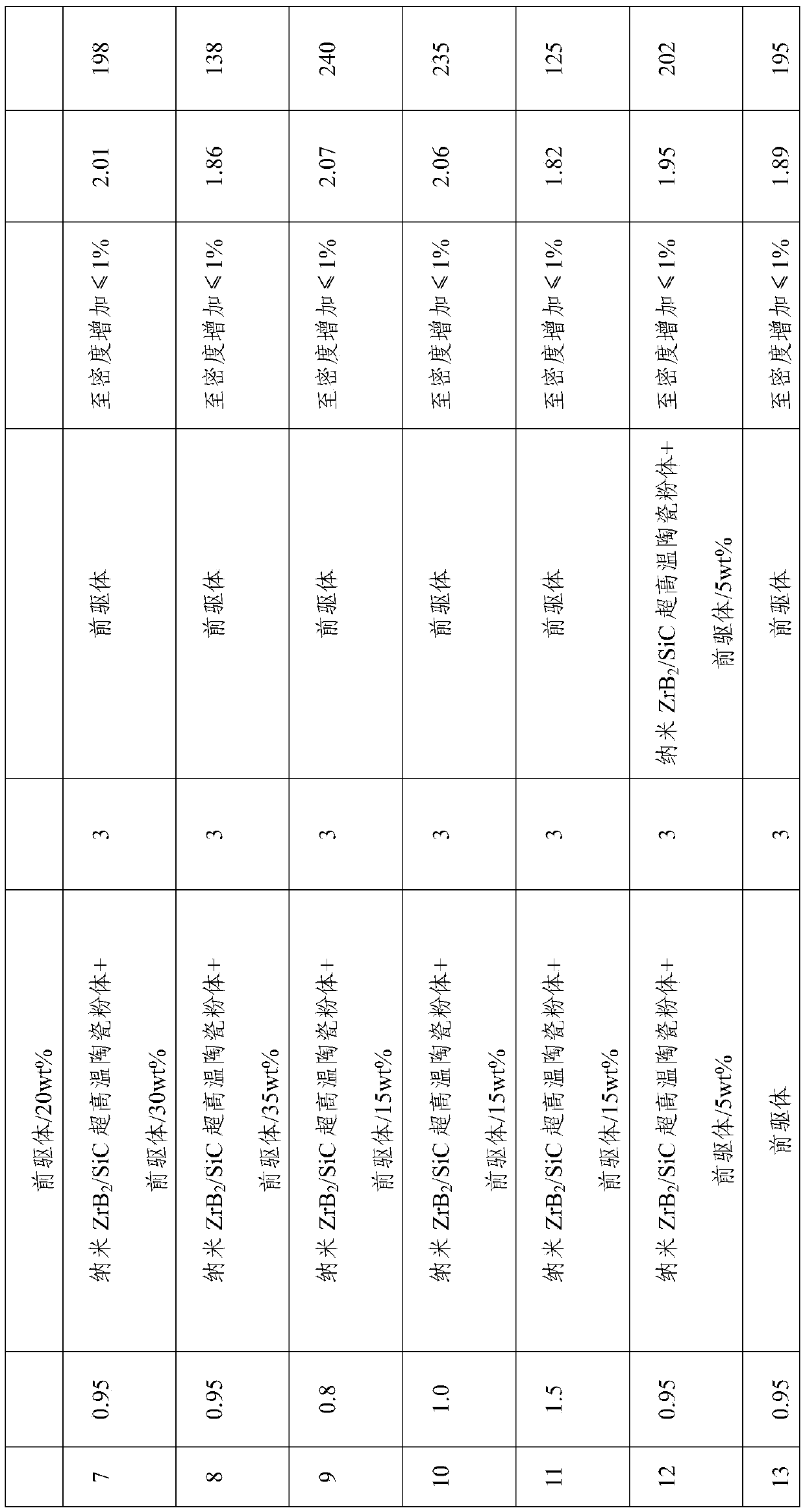

Examples

preparation example Construction

[0032] Specifically, this preparation method provided by the invention comprises the following steps:

[0033] (1) The precursor is solidified and cracked to obtain nano-ZrB 2 / SiC composite phase ultra-high temperature ceramic powder; the precursor is polyborosilazane-polyziroxane copolymer, and the precursor material used in the present invention is an existing material obtained through procurement;

[0034] (2) mixing the ultra-high temperature ceramic powder obtained in step (1) with a precursor to prepare an ultra-high temperature ceramic powder slurry;

[0035] (3) using the slurry obtained in step (2) as an impregnating solution, and performing a pre-densification treatment on the C / C composite material; and

[0036] (4) Using the precursor as the impregnation solution, the composite material after the pre-densification treatment is subjected to post-densification treatment to obtain the C / SiC-ZrB 2 composite material.

[0037] In some preferred embodiments, the presen...

Embodiment 1

[0055] S1. A carbon fiber prefabricated body with a carbon cloth laminated structure is used, and a pyC interface layer is formed on the carbon fiber prefabricated body by a chemical vapor deposition process (CVI), and the density is 0.95g / cm3. 3 low-density C / C composites.

[0056] S2. Solidify the precursor material of polyborosilazane-polyziroxane copolymer at 250°C, and then crack it in an Ar atmosphere at 1700°C for 2 hours to obtain nano-ZrB with a particle size of 200-400nm 2 / SiC ultra-high temperature ceramic powder.

[0057] S3, the nano-ZrB 2 / SiC ultra-high temperature ceramic powder and precursor (same components as S2) are mixed to prepare ultra-high temperature ceramic powder slurry, and the mass percentage of ultra-high temperature ceramic powder in the slurry is 20wt%.

[0058] S4. Using ultra-high temperature ceramic powder slurry as the impregnating liquid, the C / C composite material is densified by the PIP process. The impregnation method is atmospheric ...

Embodiment 2

[0062] The preparation methods of Example 2 and Example 3 are basically the same as those of Example 1, except that in S4, the number of PIP processes in Example 2 and Example 3 is 2 and 5, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com