Preparation method of silicon carbide and silicon carbide composite material member

A composite material component and composite material technology, applied in the field of ceramic matrix composite materials, can solve the problems of long preparation cycle and high raw material price, and achieve the effects of less harm, improved densification efficiency, and strong process matching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

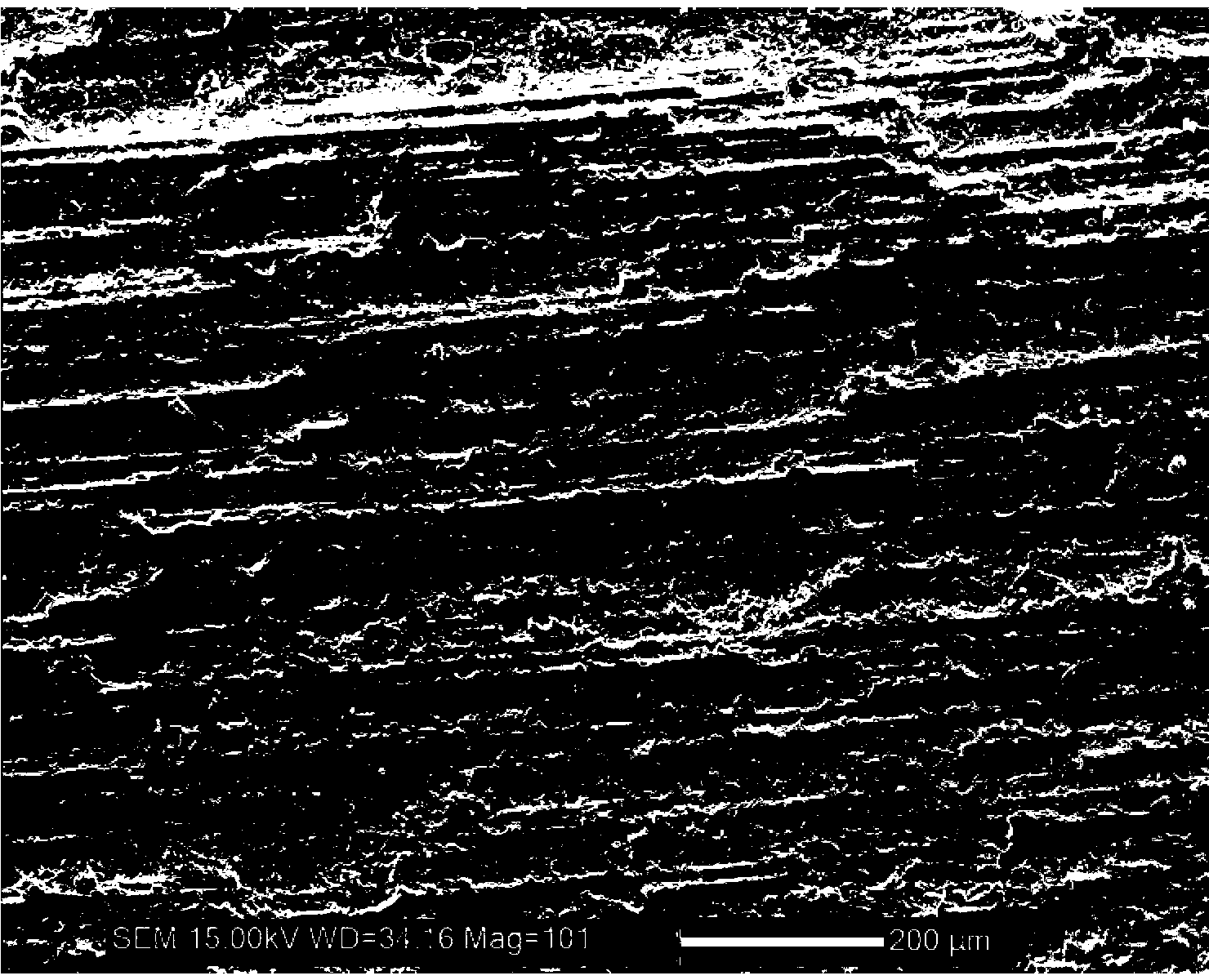

[0021] A method for preparing a silicon carbide / silicon carbide composite component, the steps are:

[0022] 1) Preparation of silicon carbide fiber prefabricated body: the silicon carbide fiber prefabricated body is prepared by two-dimensional silicon carbide cloth layering or three-dimensional weaving process;

[0023] 2) Preparation of pyrolytic carbon interface layer by chemical vapor deposition method: methane, propane, propylene or acetylene gas is used as the deposition carbon source, the dilution gas is argon, and the silicon carbide fiber prefabricated body obtained in step 1) is placed in a carbon deposition furnace Deposition is carried out, and a pyrolytic carbon interface layer is deposited on the surface of the silicon carbide fiber; the process parameters are as follows: the deposition temperature is 850-1400°C, the deposition pressure is 0.1-20KPa, and the deposition time is 1-100 hours. The thickness of the pyrolytic carbon interface layer on the surface of th...

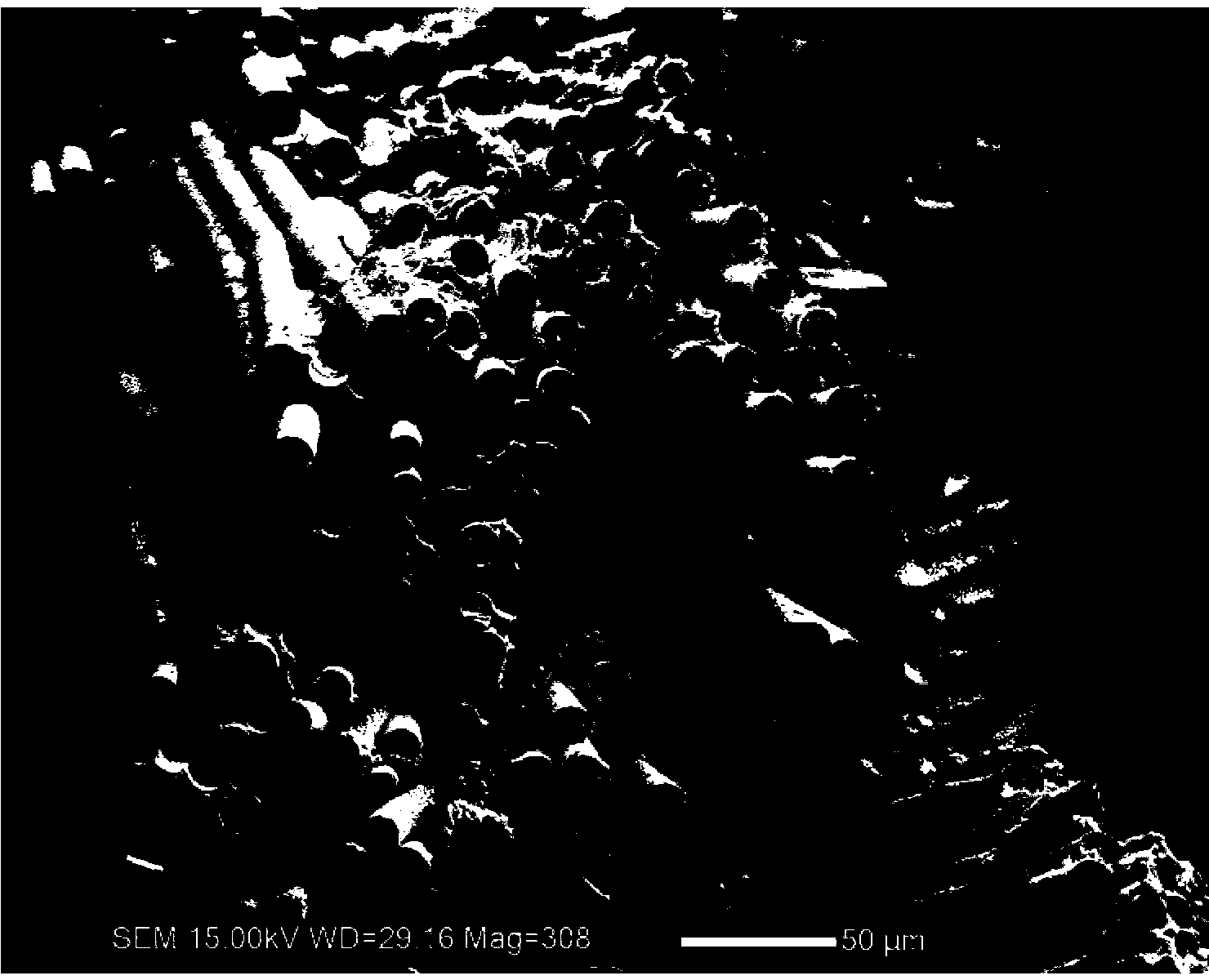

Embodiment 1

[0035] A method for preparing a silicon carbide / silicon carbide composite component, comprising the following steps:

[0036] 1) Using continuous silicon carbide fiber as raw material, it is first woven into plain weave, and then the arc-shaped prefabricated body is made with the aid of graphite tooling by sewing process;

[0037] 2) Using methane as the carbon source gas, the preform obtained in step 1) is placed in a deposition furnace for chemical vapor deposition, and a pyrolytic carbon interface layer is deposited on the surface of the silicon carbide fiber of the preform. The process conditions of the chemical vapor deposition are as follows: the deposition temperature is 900° C., the deposition pressure is 0.15 KPa, and the deposition time is 40 hours. The thickness of the interface layer of pyrolytic carbon is 0.17 μm;

[0038] 3) Using a vacuum-assisted method, the prepared impregnation phase was preheated to 60°C, and then introduced into the silicon carbide fiber pre...

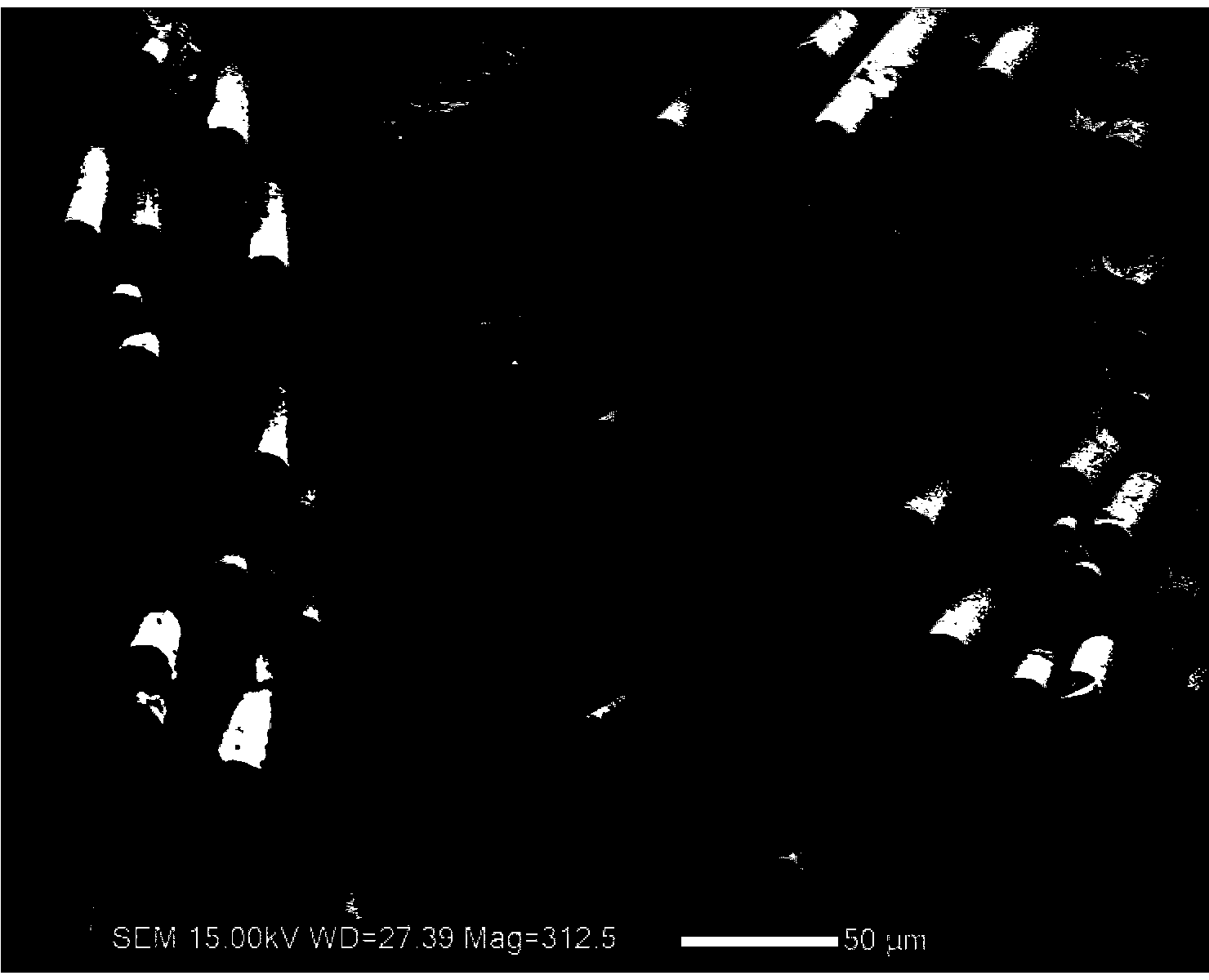

Embodiment 2

[0042] A method for preparing a silicon carbide / silicon carbide composite component, comprising the following steps:

[0043] 1) Using continuous silicon carbide fiber as raw material, weave five pieces of satin cloth first, and then form a T-shaped prefabricated body in graphite tooling by two-dimensional layering;

[0044] 2) Using propane as the carbon source gas, the preform is placed in a deposition furnace for chemical vapor deposition, and a pyrolytic carbon interface layer is deposited on the surface of the silicon carbide fiber of the preform. The process conditions of the chemical vapor deposition are as follows: the deposition temperature is 1200° C., the deposition pressure is 1.0 KPa, and the deposition time is 20 hours. The thickness of the interface layer of pyrolytic carbon is about 0.15 μm;

[0045] 3) The prepared impregnated phase was introduced into the silicon carbide preform deposited with the pyrolytic carbon interface layer by means of vacuum assistanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com