Artificial graphite negative-pole material, preparation method therefor and lithium-ion battery

An artificial graphite negative electrode and graphitization technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of high preparation cost, low energy density, poor coating uniformity, etc., and improve the degree of anisotropy. High performance, excellent electrochemical performance, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

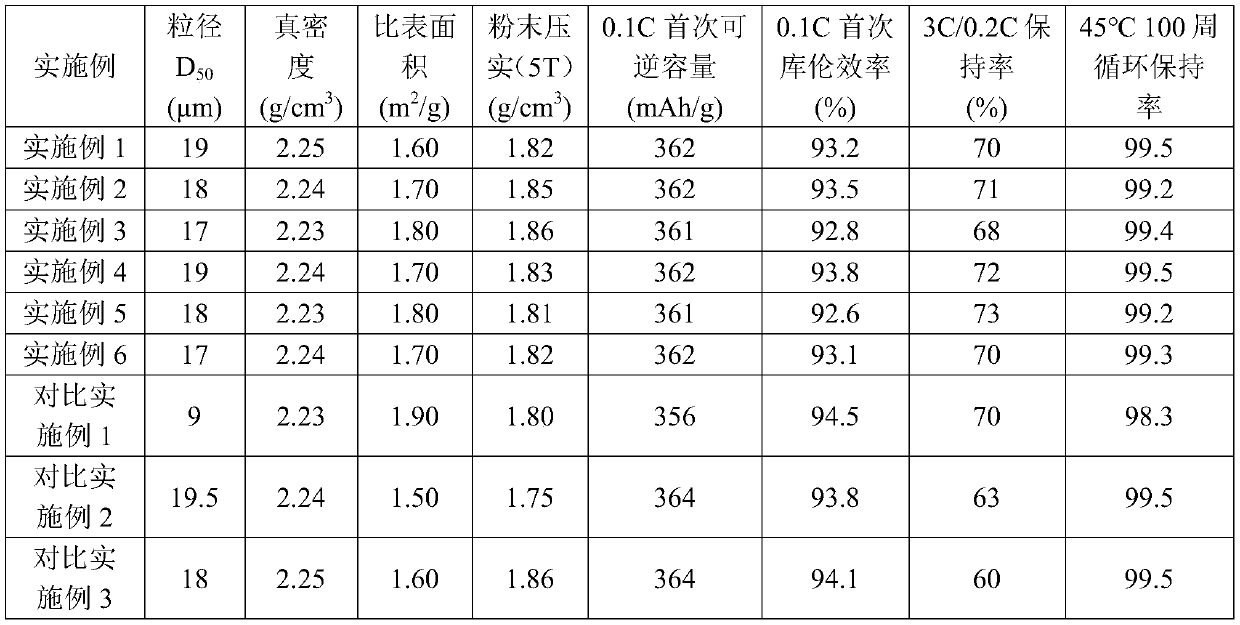

Examples

Embodiment 1

[0029] The needle coke with a volatile content of 0.5% was pulverized and shaped by a roll mill-shaper integrated machine to obtain primary particles A, and the average particle diameter D50 of the primary particles A was controlled to be 8 μm. Take part of the primary particles A and the cracking oil coating agent and put them into the vacuum kneader according to the mass ratio of 100:8, first knead at 120°C for 2 hours at normal pressure, then switch to vacuum mode and knead at 250°C for 4 hours, and put the kneaded material into the vertical kneader In the reaction kettle, under the protection of nitrogen, the temperature was raised to 400°C at 5°C / min for 2 hours, and then the temperature was raised to 550°C at 3°C / min for 4 hours. After cooling, sieve to obtain particle B once; Particle A and petroleum asphalt with a softening point of 250°C and an average particle size of 7 μm were mixed evenly at a mass ratio of 100:10 and put into a drum furnace. Under nitrogen protecti...

Embodiment 2

[0031]The needle coke with a volatile content of 1% was pulverized and shaped by a roll mill-shaper integrated machine to obtain primary particles A, and the average particle diameter D50 of the primary particles A was controlled to be 8 μm. Take part of the primary granules A and the sucrose coating agent and put them into the vacuum kneader according to the mass ratio of 100:5, first knead at 120°C for 2 hours at normal pressure, then transfer to the vacuum mode and knead at 250°C for 4 hours, put the kneaded material into the vertical kneader In the reaction kettle, under the protection of nitrogen, heat at 5°C / min to 400°C for 2 hours, then heat at 3°C / min to 600°C for 2 hours, and sieve after cooling to obtain primary particles B; take part of the primary particles A and petroleum asphalt with a softening point of 150°C and an average particle size of 7 μm are mixed evenly at a mass ratio of 100:15 and put into a drum furnace. Under nitrogen protection, the temperature is ...

Embodiment 3

[0033] The needle coke with a volatile content of 5% is coarsely crushed to below 5 mesh, then modified at 900°C for 4 hours at high temperature, and then crushed and shaped by a roller mill-shaping machine to obtain primary granules A, and the primary granules A are controlled The average particle diameter D50 is 8 μm. Take part of the primary particles A and phenolic resin oil coating agent and put them into the vacuum kneader according to the mass ratio of 100:8, first knead at 120°C under normal pressure for 2 hours, then transfer to vacuum mode and knead at 250°C for 4 hours, put the kneaded material into In a vertical reactor, under the protection of nitrogen, heat at 5°C / min to 400°C for 2 hours, then heat at 3°C / min to 600°C for 2 hours, and sieve after cooling to obtain primary particle B; Primary particle A and petroleum resin with a softening point of 150°C and an average particle size of 9 μm are mixed evenly at a mass ratio of 100:12 and put into a roller furnace....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com