Technological control method for iron casting shrinkage porosity defect

A technology of process control and iron castings, which is applied in the field of process control of shrinkage defects of iron castings, can solve the problems of high scrap rate and achieve the effect of reducing scrap rate, good effect and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

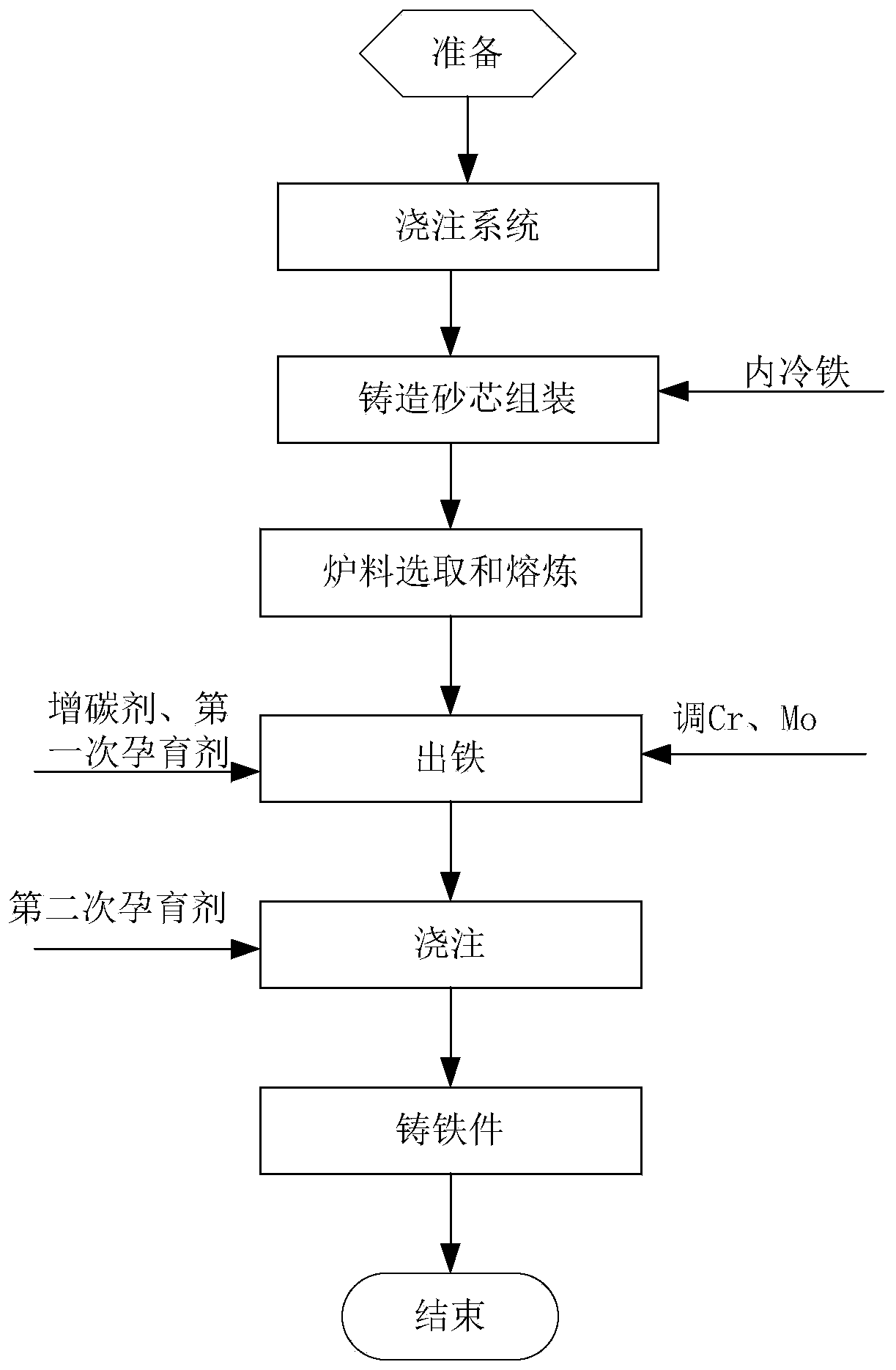

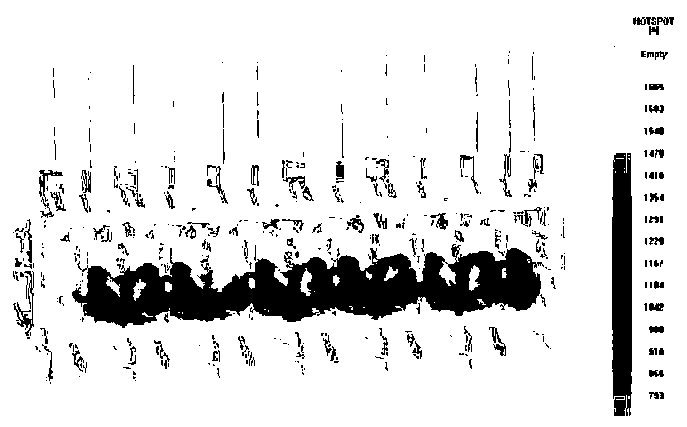

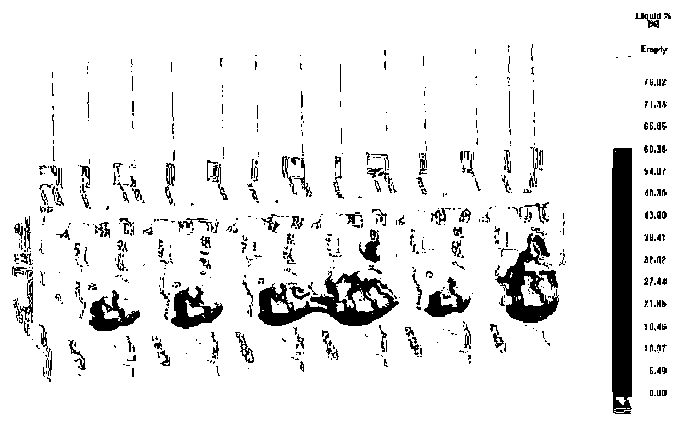

[0061] Embodiment 1: A process control method for shrinkage defects of a high-strength TCD cylinder head, comprising the following steps:

[0062] In the first step, a combination of vertical pouring and stepped pouring is used to set gates at the bottom and middle of the mold, and to set gates and runners evenly according to structural characteristics. The shape of the gate is set as ellipse.

[0063] The second step, sand core assembly: the internal cooling iron is set in the area of the row of bolt holes closest to the isolated thermal phase area. The internal cooling iron adopts the open cylindrical shape of 1mm tinned A3 steel.

[0064] In the third step, the furnace charge is made of 65% scrap steel and 35% returned iron; the composition and content of the charge, according to the percentage of the total mass of the charge, include: C%=3.23%, Si%=1.80%, Mn%=0.5% , P%≤0.06%, S%=0.11%, Cu%=0.85%, Mo%=0.10%, Sn%=0.08%, Cr%=0.05%, and the balance is Fe.

[0065] The med...

Embodiment 2

[0080] The invention provides a process control method for the shrinkage defect of a cylinder head for an automobile, said method comprising the steps of:

[0081] The first step is to use vertical step casting combined with pouring process.

[0082] The shape of the flat gate near the isolated thermal phase area is a long strip shape, and the gate is realized by compressing one side of the circular gate in a direction away from the isolated thermal phase area, so the shape of the gate changes, but the circumference The sum area remains the same, but the distance between the overall gate and the isolated thermal phase area increases, and the shape of the gate changes accordingly.

[0083] The second step, sand core assembly: Use 0.8mm tin-plated A3 steel open cylindrical internal cooling iron to locally chill the three rows of bolt holes with the most poor feeding.

[0084] In the third step, the charge is made of 75% scrap steel and 25% returned iron, and the charge composit...

Embodiment 3

[0094] The invention provides a process control method for the shrinkage defect of a cast iron cylinder head, and the method comprises the following steps:

[0095] In the first step, the pouring system adopts the vertical step pouring process;

[0096] The shape of the flat gate is long, and the position of the gate is far away from the isolated thermal phase area relative to the round gate.

[0097] The second step, sand core assembly: use 1.2mm tin-plated A3 steel open cylindrical inner cooling iron to locally chill the row of bolt holes with poor feeding.

[0098] In the third step, the furnace charge is made of 70% scrap steel and 30% returned iron, and the charge composition is adjusted as follows: C%=3.21%, Si%=1.85%, Mn%=0.6%, P%≤0.06%, S% = 0.11%, Cu% = 0.90%, Mo% = 0.15%, Sn% = 0.08%, Cr% = 0.10%, and the balance is Fe.

[0099] The intermediate frequency coreless induction furnace is adopted, and the temperature is controlled at 1540°C for high temperature melting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com