Automatic screening device for neodymium iron boron magnetic powder and automatic screening method thereof

An NdFeB automatic screening technology, which is applied in the field of NdFeB magnetic powder automatic screening device, screening device, and NdFeB magnetic powder automatic screening, can solve the problems of low screening efficiency and poor screening effect, and achieve Improve screening efficiency and screening quality, ensure screening effect, and ensure the effect of dispersion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

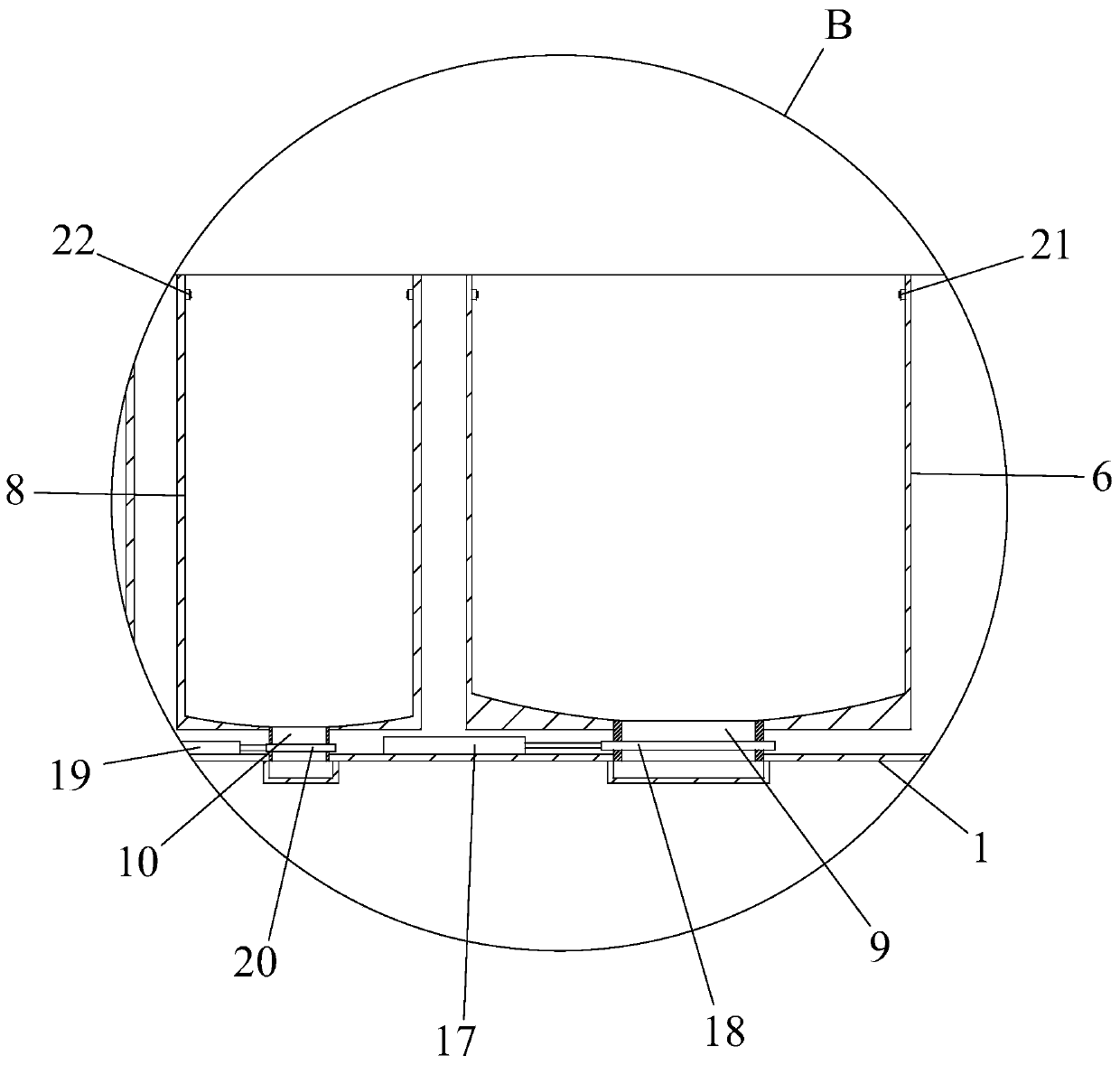

[0056] see Figure 1-5 , This embodiment provides an automatic screening device for NdFeB magnetic powder, which is capable of screening externally fed NdFeB magnetic powder to screen out magnetic powders with different particle sizes and non-magnetic impurities. Wherein, the NdFeB magnetic powder automatic screening device includes a screening barrel 1, a dispersing mechanism, an offset mechanism, a collecting mechanism, a detecting mechanism and a controller.

[0057] The screening barrel 1 can adopt a round barrel or a square barrel, and can also adopt barrels of other shapes. In this embodiment, in order to prevent the NdFeB magnetic powder from being adsorbed on the inner wall of the screening bucket 1, the screening bucket 1 is made of non-metallic materials, such as plastic and wood materials. Screening barrel 1 is used as the place for screening NdFeB magnetic powder in this embodiment, and its size can be set according to the screening amount of NdFeB magnetic powder...

Embodiment 2

[0070] This implementation provides an automatic screening device for NdFeB magnetic powder, which is similar to the device in Embodiment 1, the only difference is that the magnet 5 in this embodiment is an electromagnet, and the functions of the controller are increased. The controller is also used to adjust the magnetic force of each magnet 5 according to the particle size range of the NdFeB magnetic powder, by querying the data correspondence in a preset particle size-magnetic force comparison table. Among them, there is a one-to-one data correspondence between the particle size range and the magnetic force in the particle size-magnetic force comparison table. In this way, in practical applications, the controller can obtain the magnetic force required by each magnet 5 by querying the particle size range of the NdFeB magnetic powder, so as to adjust each magnet 5, so that the NdFeB magnetic powder will be adjusted according to the magnetic force. Offset, so that the magneti...

Embodiment 3

[0072] see Figure 6 , this embodiment provides an automatic sieving device for NdFeB magnetic powder, on the basis of Embodiment 1, a part of the structure belonging to the offset mechanism is added. Wherein, the offset mechanism also includes a plurality of air nozzles 11 and a plurality of electronic air valves 12 . A plurality of air nozzles 11 correspond to a plurality of magnets 5 respectively, and each air nozzle 11 blows air toward the corresponding magnet 5 to increase the deflection of the NdFeB magnetic powder in the corresponding particle size range. The plurality of electronic air valves 12 correspond to the plurality of air nozzles 11 respectively, and each electronic air valve 12 is installed on the corresponding air nozzle 11 and is used to adjust the intake air volume of the corresponding air nozzle 11 . Among them, the controller is also used to query the data correspondence in a preset particle size-intake amount comparison table according to the particle s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com