Constant-pressure energy-saving system of blowing and suction type centralized cotton suction device

An energy-saving system, blowing and sucking technology, applied in textiles and papermaking, etc., can solve the problems of power and energy waste, troublesome device control, unfavorable use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

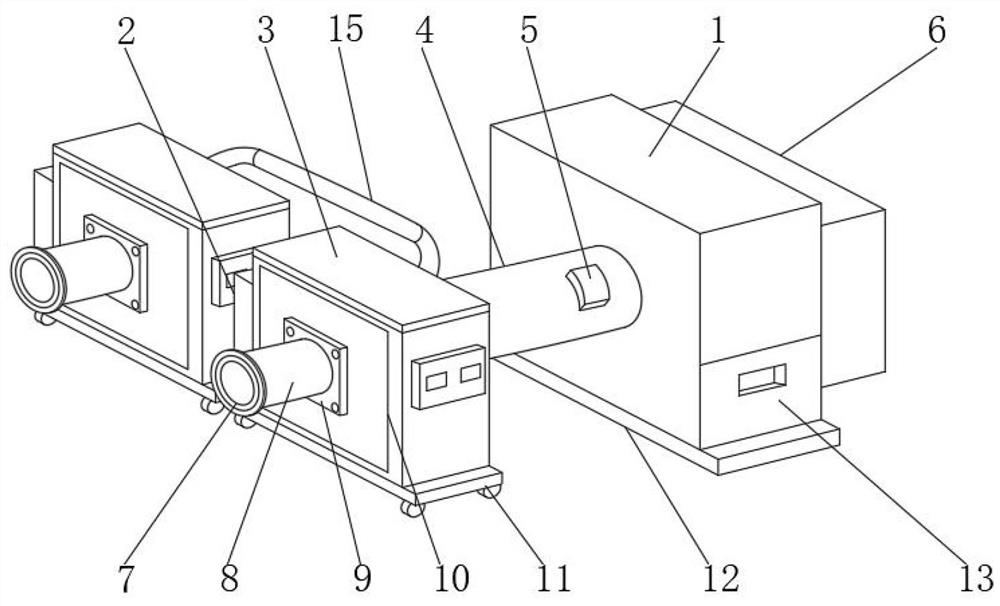

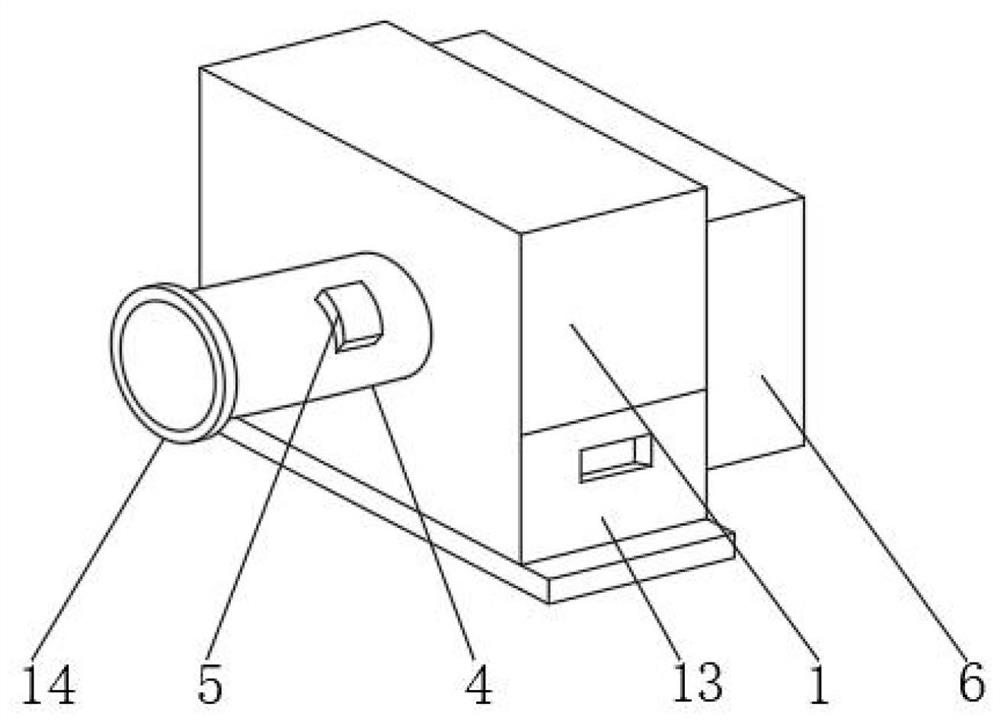

[0028] like Figure 1-3 As shown, the constant pressure energy-saving system of blowing and suctioning centralized cotton suction device includes centralized cotton suction box 1 and itinerant blowing and suction cleaning machine 3, and a cotton suction air duct 4 is installed between the centralized cotton suction box 1 and itinerant blowing and suction cleaning machine 3 With the connection mechanism 14, the rear end of the centralized cotton suction box 1 is equipped with a cotton suction motor 6, the bottom of the centralized cotton suction box 1 is equipped with a positioning base 12, and the outside of the centralized cotton suction box 1 is equipped with a cotton suction collection box 13, the suction The outer wall of the cotton air duct 4 is equipped with a motor drive control system 5 .

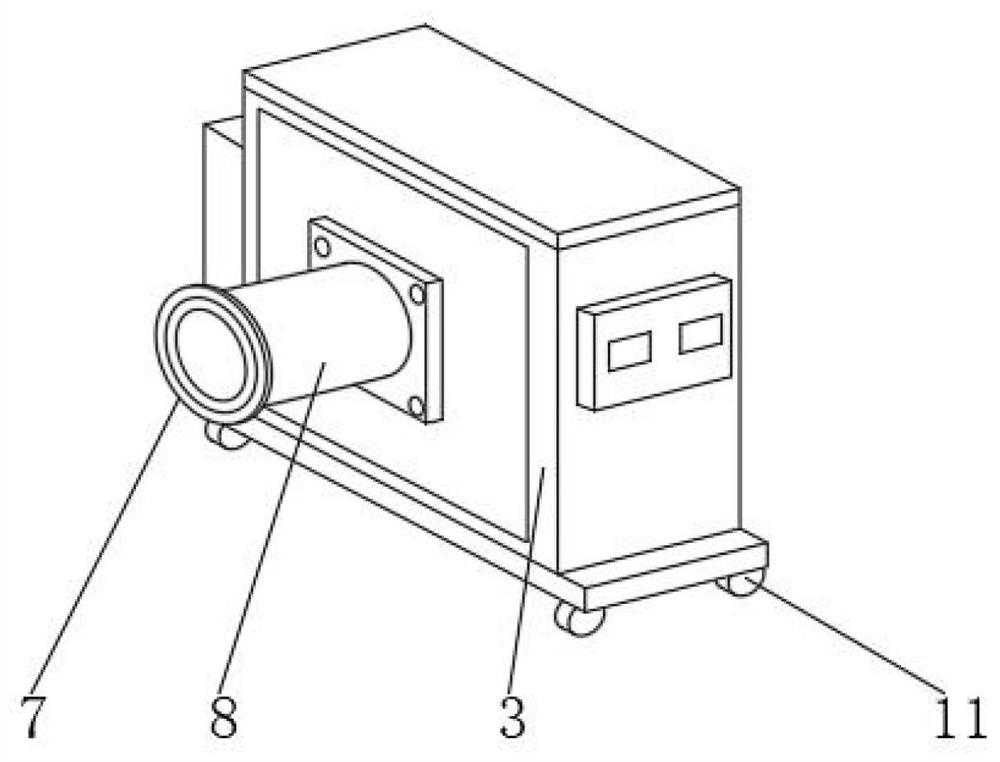

[0029] Further, the itinerant blowing and suction cleaning machine 3 is provided with 10-15 groups, and the outside of the itinerant blowing and suction cleaning machine 3 is equipp...

Embodiment 2

[0033] On the basis of Example 1, as Figure 1-6 As shown, the constant pressure energy-saving system of blowing and suctioning centralized cotton suction device includes centralized cotton suction box 1 and itinerant blowing and suction cleaning machine 3, and a cotton suction air duct 4 is installed between the centralized cotton suction box 1 and itinerant blowing and suction cleaning machine 3 With the connection mechanism 14, the rear end of the centralized cotton suction box 1 is equipped with a cotton suction motor 6, the bottom of the centralized cotton suction box 1 is equipped with a positioning base 12, and the outside of the centralized cotton suction box 1 is equipped with a cotton suction collection box 13, the suction The outer wall of the cotton air duct 4 is equipped with a motor drive control system 5 .

[0034] Further, the interior of the centralized cotton suction box 1 is provided with a circuit breaker, a power supply module, a fast fuse, a power supply ...

Embodiment 3

[0037] On the basis of Example 2, such as Figure 1-6 As shown, the constant pressure energy-saving system of blowing and suctioning centralized cotton suction device includes centralized cotton suction box 1 and itinerant blowing and suction cleaning machine 3, and a cotton suction air duct 4 is installed between the centralized cotton suction box 1 and itinerant blowing and suction cleaning machine 3 With the connection mechanism 14, the rear end of the centralized cotton suction box 1 is equipped with a cotton suction motor 6, the bottom of the centralized cotton suction box 1 is equipped with a positioning base 12, and the outside of the centralized cotton suction box 1 is equipped with a cotton suction collection box 13, the suction The outer wall of the cotton air duct 4 is equipped with a motor drive control system 5 .

[0038] Further, the motor drive control system 5 is equipped with a cleaning machine number detection module, a pressure sensor module, a communication...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com